Established in 2013, Shanghai VSUN Technology Co., Ltd. is a high-tech enterprise with R&D, production, sales, GMP verification, sales for pharmaceutical machinery, automation equipment control system research and upgrading.

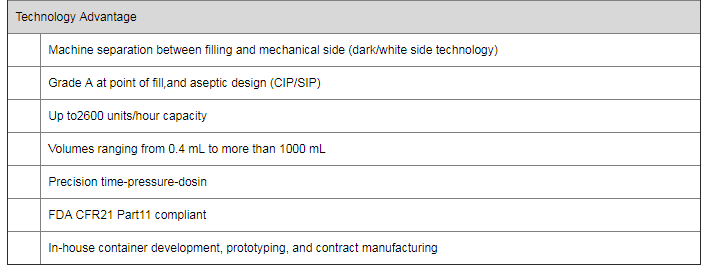

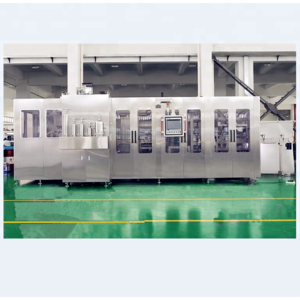

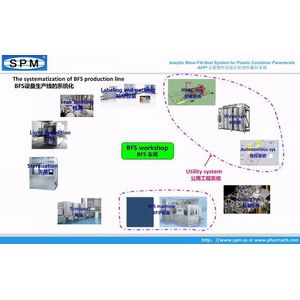

VSUN are able to provide the total solution of pharmaceutical machinery for both international and domestic market. With our more than ten year of pharmaceutical experience, we can successfully provide pharmaceutical engineering project program in compliance with GMP standard for global customers. VSUN owns the first BFS technology R&D team in China and succeeded in manufacturing aseptic Blow-Fill-Seal 3 in 1 machine learned from Italian design in 2015. The main features of BFS machine are high integration, small space area and low energy consumption. All processes can be completed under aseptic conditions. It has high performance and high utilization rate of raw material. Meantime we can provide total solution for BFS technology and accept turn key projects.

VSUN will continue to promote quality system for pharmaceutical machinery, expand sale channel, actively develop markets for our own brand, independently create new design, follow the philosophy of “Best service & Quality provided” and keep our promises to serve global customers. VSUN will abide the philosophy of “Credibility, Innovation, Win-win and Excellence”, strengthen core competitiveness, make progress and move forward to the monument of “Chinese best pharmaceutical industry” all the time.

The Blow-Fill-Seal Technique has been developed so that formation of the container, filling and sealing takes place in a single machine under a controlled environment that enables the packaging of a pharmaceutical liquid in an aseptic manner.

As the container is made, filled and sealed within a single machine and the process is protected using a sterile air shower and additionally, all process media (solution, air etc.) are sterile filtered, the chance of contamination is very remote. Adding to the fact that during the whole cycle, open containers remain exposed to the clean room air for less than 1.5 seconds, the Blow-Fill-Seal technology becomes the process of choice where contamination of particle matter and microbial contamination is a primary concern.

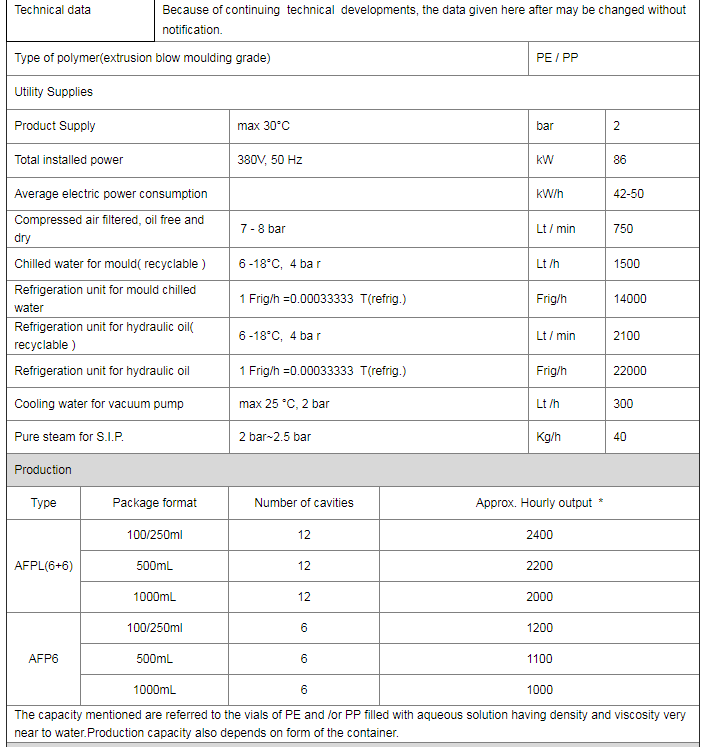

Technical Date:

Extrusion

continuously extruded in a tubular shape. Aseptic air blows

to the plastic tube parison,and the parison goes through

the forming mould.

Blowing

The main forming mould closes and the bottom of plastic parison is

sealed. The cutting knife cut the parison.The top of plastic parison is

located by the open protecting clamp.Aseptic air continuously protects the open tube parison.

The plastic material is formed into containers as determined by the

design of the mould by vacuum and/or aseptic compressed air.

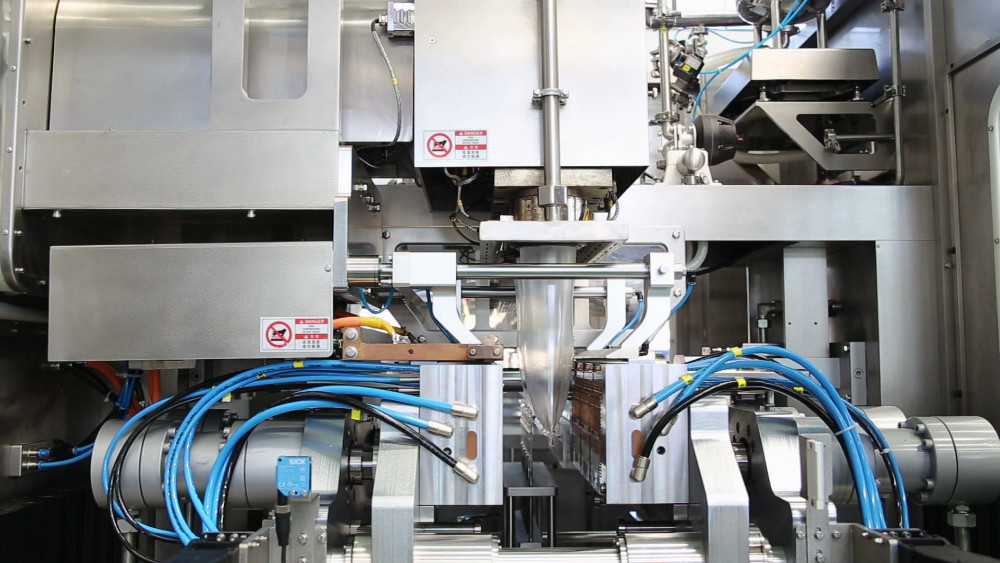

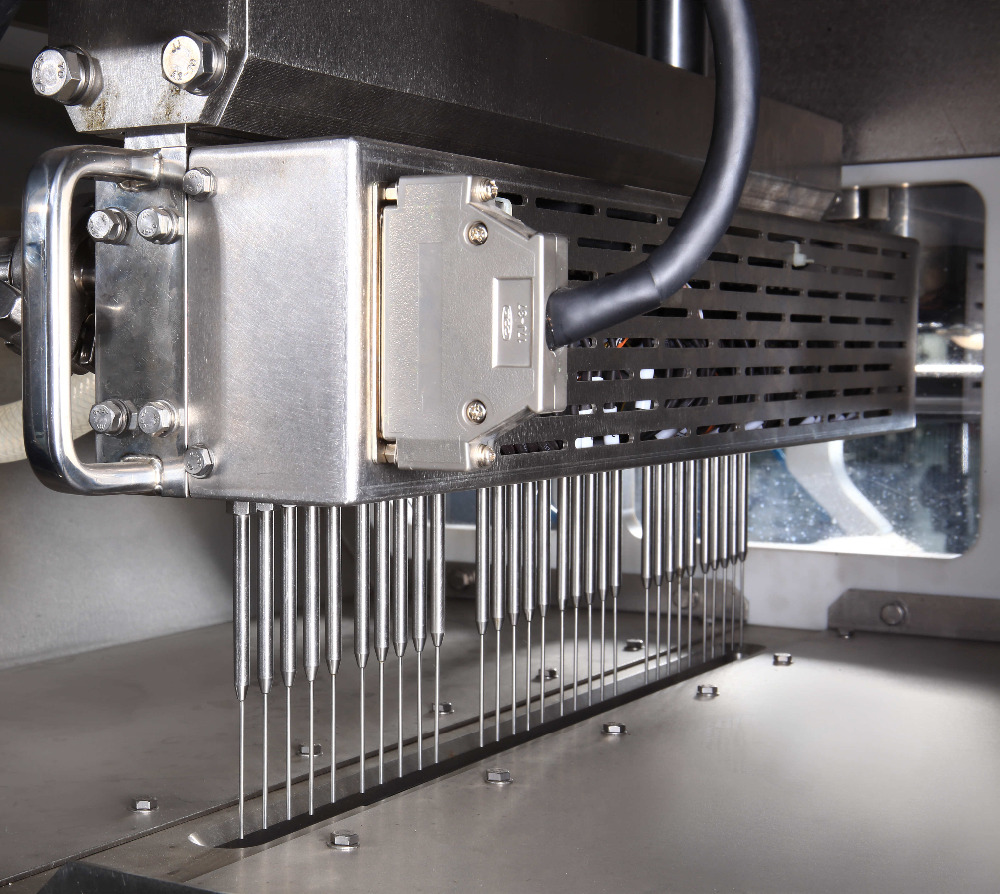

Filling

The containers are filled immediately and the air in the container is

displaced .In the filling process,the containers are protected by the

aseptic air as Grade A.

Sealing

At the same time,the tube parison between top of plastic mould and

the open protecting clamp remains semi-melting condition,and then

the sealed mould closes and forms the top of the container and keeps

the container sealed.

Outfeeding

After sealed,the mould is opened,and the containers are totally formed,filled,sealed and is ready to outfeed.Then the machine starts the next cycle.

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

Packaging

China

China