Product Description:

ITEM | UNIT | DATA | |||

Injection | Screw Diameter | mm | 45 | 50 | 55 |

Screw L/D Ratio | L/D | 23.1 | 20.6 | 18.7 | |

Injection Volume | cm3 | 374 | 461 | 558 | |

Shot Weight | g | 340 | 420 | 508 | |

Injection Pressure | Mpa | 210 | 170 | 141 | |

Clamping | Clamping Force | KN | 2080 | ||

Opening Stroke | mm | 475 | |||

Mould Thickness(Min-Max) | mm | 200-520 | |||

Space Between Tie-Bars | mm | 515×515 | |||

Ejector Force | KN | 62 | |||

Ejector Stroke | mm | 165 | |||

General | Motor Power | KW | 18.5 | ||

Heater | KW | 18.6 | |||

Pump Pressure | Mpa | 16 | |||

Machine Dimension | m | 5.7×1.4×2.3 | |||

Machine Weight | T | 6.6 | |||

Mould Orientation Ring Diameter | mm | Φ160 | |||

Nozzle Radius | mm | SR15 |

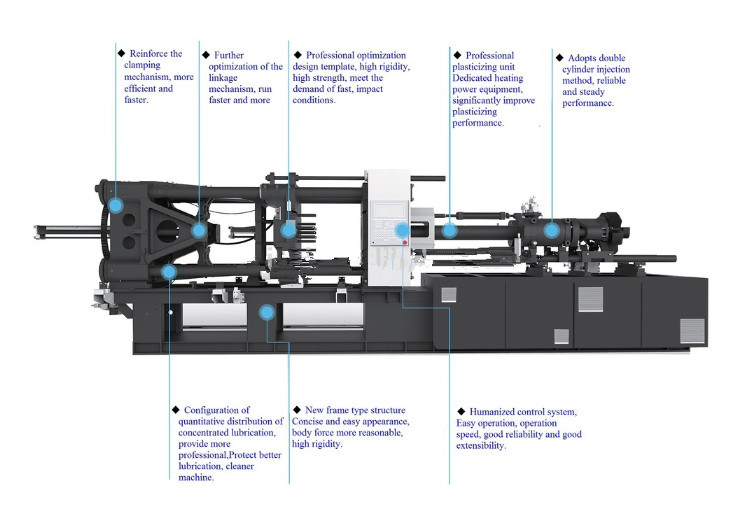

Improve The Production Efficiency

Quick Response And High Efficiency

Injection molding machine to achieve maximum output in 0.05 s

50 rpm can be up to 140 bar

High Repeat Precision, Save Raw Materials

Repeated injection precision can reach <=3%

Pressure Is Stable, Improve the Quality Of Molding

Pressure fluctuation quantity is less than + / - 0.5 bar

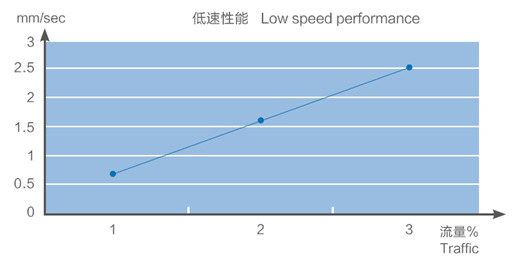

Stable At Low Speed

Closedloop control pressure and flow, at low pressure and low flow operation performance is particularly

outstanding, shoot rubber speed in less than 1 mm/SEC without crawling, pulse, high stability. System according to the actual product process requirements, set arbitrary pressure and flow, avoid excess heat generation, the oil temperature relative to the traditional injection molding machine is stable. In addition, the pressure

flow automatic compensation when motion, maintain the stability of the pressure and flow rate, high control accuracy and repeat precision.

Machine Service Life Longer And Cleaner Working Environment

Less Noise Emissions

Low Heat And Cooling Energy Demand Is Low,

More Suitable For Production Environment With Air Conditioning

Injection molding machine boot into the steady-state oil temperature rise of 8°C to 10°C

China

China