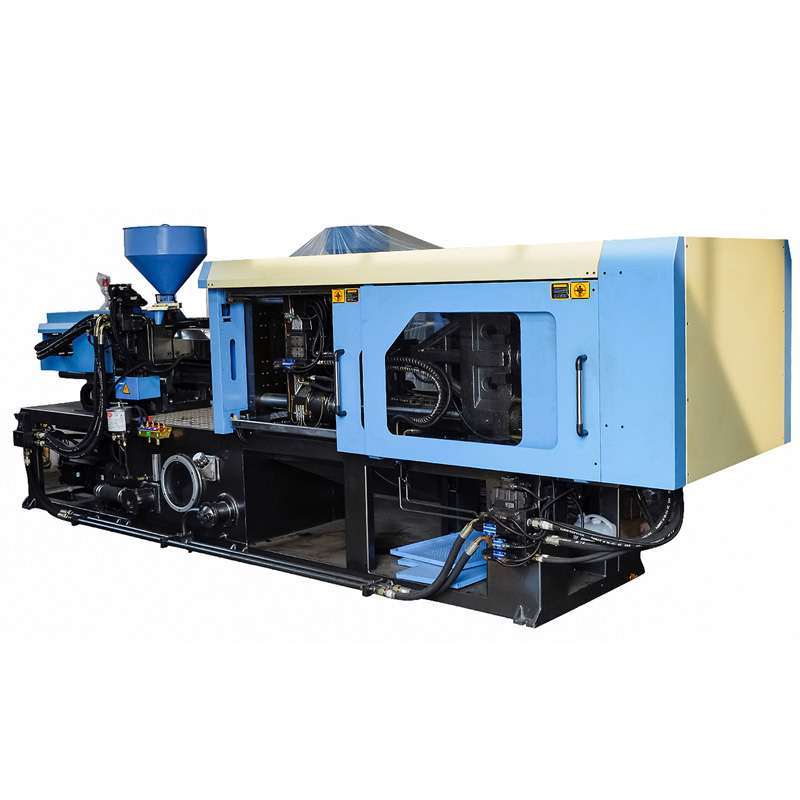

We are PVC pipe fittings injection molding machine in China , our machine can production PVC products with all kinds of design, our machines are known for the features like durability & sturdy construction.

PVC pipe fittings injection molding machine is the most mature product of all our machinery,even we could design the machine according customer's requirement,for example,for PVC pipe there are water-supply pipe and drain pipe,if you need to make water-supply pipe fittings,we could supply you with big injection unit+small clamp unit type ,which could lower your cost,improve efficiency,further reduce the single product cost,if you visit us ,we will show you all kinds of PVC products which made by our machines,and help you solve all technical problems regarding PVC products .and provide you very accurate solution.

we are specialized in making injection machine and engineering ,with 20 years experience ,hope we could become your good friend in China,no matter you buy our machine or not .

Our PVC pipe fittings injection molding machine Advantages;

Faster response stable high rigidity

Accurate flexible low rejection rate

Molding data memory system

Energy saving, Durable

High rigidity, long working life

Energy saving 20% to 80%

Timely after-sales services

Some of the important features:

Clamping system: Faster response, steable and high rigidity

Injection system: Accurate and flexible, lower rejection rate

Control system: Computer and simple operation, molding data memory system

Power system: Energy saving, high efficient and precise

Metal parts: The thickness of our frame, metal plate and wallboard are thicker than other company.

Other Information

Ceramic heating loop: Uniform heating, better thermal insulation properties so good for production

Visiable lubrication system: On time clean, avoid cast steel parts abrasion and broken.

Oil treasure: Filter of hydraulic oil, good for pump and valves

Long working life: Imported spare parts and updated version

Aftersales service: Professional & timely

Delivery time: 30-60 days

Port of dispatch: Shanghai

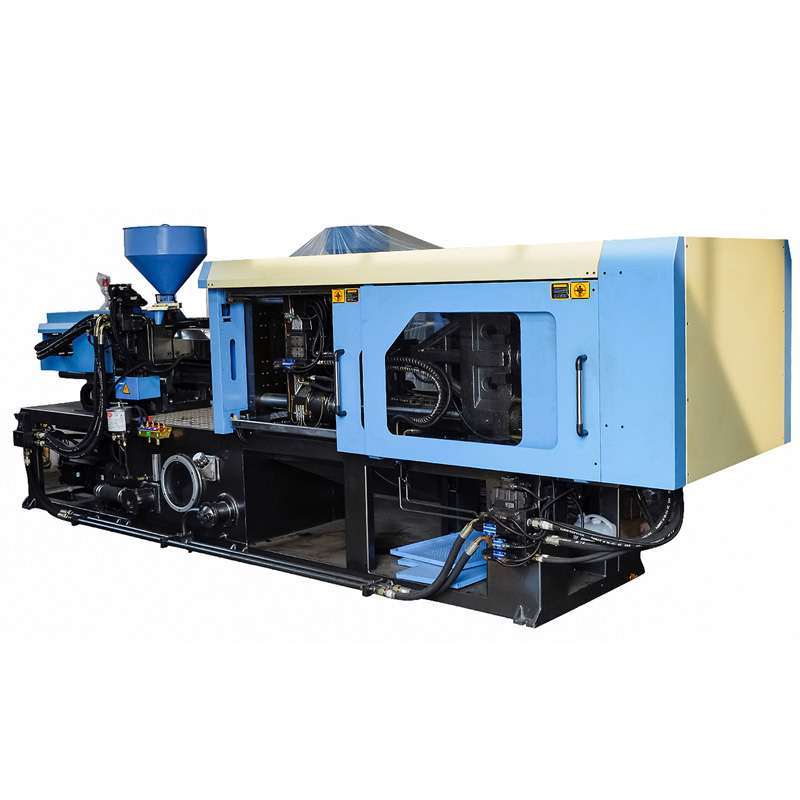

PVC pipe fittings injection molding machine is the most mature product of all our machinery,even we could design the machine according customer's requirement,for example,for PVC pipe there are water-supply pipe and drain pipe,if you need to make water-supply pipe fittings,we could supply you with big injection unit+small clamp unit type ,which could lower your cost,improve efficiency,further reduce the single product cost,if you visit us ,we will show you all kinds of PVC products which made by our machines,and help you solve all technical problems regarding PVC products .and provide you very accurate solution.

we are specialized in making injection machine and engineering ,with 20 years experience ,hope we could become your good friend in China,no matter you buy our machine or not .

Our PVC pipe fittings injection molding machine Advantages;

Faster response stable high rigidity

Accurate flexible low rejection rate

Molding data memory system

Energy saving, Durable

High rigidity, long working life

Energy saving 20% to 80%

Timely after-sales services

Some of the important features:

Clamping system: Faster response, steable and high rigidity

Injection system: Accurate and flexible, lower rejection rate

Control system: Computer and simple operation, molding data memory system

Power system: Energy saving, high efficient and precise

Metal parts: The thickness of our frame, metal plate and wallboard are thicker than other company.

Other Information

Ceramic heating loop: Uniform heating, better thermal insulation properties so good for production

Visiable lubrication system: On time clean, avoid cast steel parts abrasion and broken.

Oil treasure: Filter of hydraulic oil, good for pump and valves

Long working life: Imported spare parts and updated version

Aftersales service: Professional & timely

Delivery time: 30-60 days

Port of dispatch: Shanghai

|

INJECTION UNIT |

Unit | LSF-168 | ||

| A | B | C | ||

| Screw Diameter | Mm | 40 | 45 | 50 |

| Screw L/D Ratio | L/D | 22.3 | 20 | 18.1 |

| Short Size | Cm3 | 301 | 381 | 471 |

| Injection weight | G | 274 | 347 | 428 |

| Injection Rate | g/s | 124 | 157 | 194 |

| Plasticizing capacity | g/s | 13.6 | 17.8 | 22.7 |

| Injection Pressure | Mpa | 247 | 196 | 158 |

| Screw Speed | Rpm | 0-190 | ||

|

CLAMPING UNIT |

Clamp Force | KN | 1680 | |

| Space Between Tie Bars | mm | 460*460 | ||

| Toggle Stroke | mm | 450 | ||

| Max. Mold Height | mm | 520 | ||

| Min. Mold Height | mm | 180 | ||

| Ejector Stroke | mm | 140 | ||

| Ejector Tonnage | KN | 39.6 | ||

| Ejector Number | P | 5 | ||

|

OTHERS |

Max. pump Pressure | Mpa | 16 | |

| Pump motor powder | Kw | 15 | ||

| Heater Power | Kw | 9.75 | ||

| Machine Dimension(L*W*H) | M | 5.1*1.5*2.1 | ||

| Oil Tank Capacity | L | 280 | ||

| Machine Weight | T | 5.9 |

China

China