High - precision stainless steel straight seam welded pipe tube making machine equipment production line

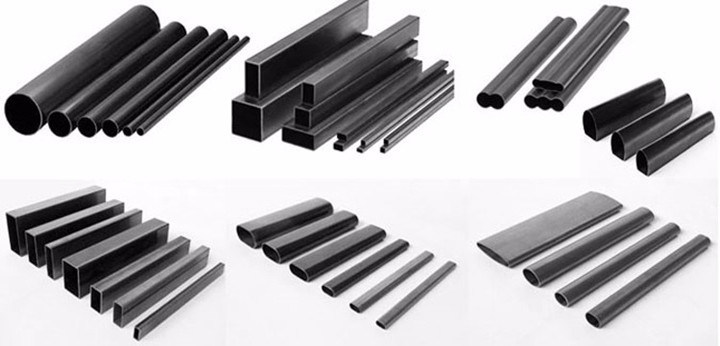

1: The pipes made by our steel pipe making machine line

Pipe produced by our erw pipe mill can be used for below:

2. Heating Pipe 8. Structural Support Steel Pipe

3. Low-pressure Process Pipeline 9. Industrial Steel Pipes

4. Low Pressure Fire Fighting Pipeline 10. Decoration Pipe

5. Sewage Pipes 11. Water Pipe

6. Steel Scaffolding Pipe 12. Building pipe

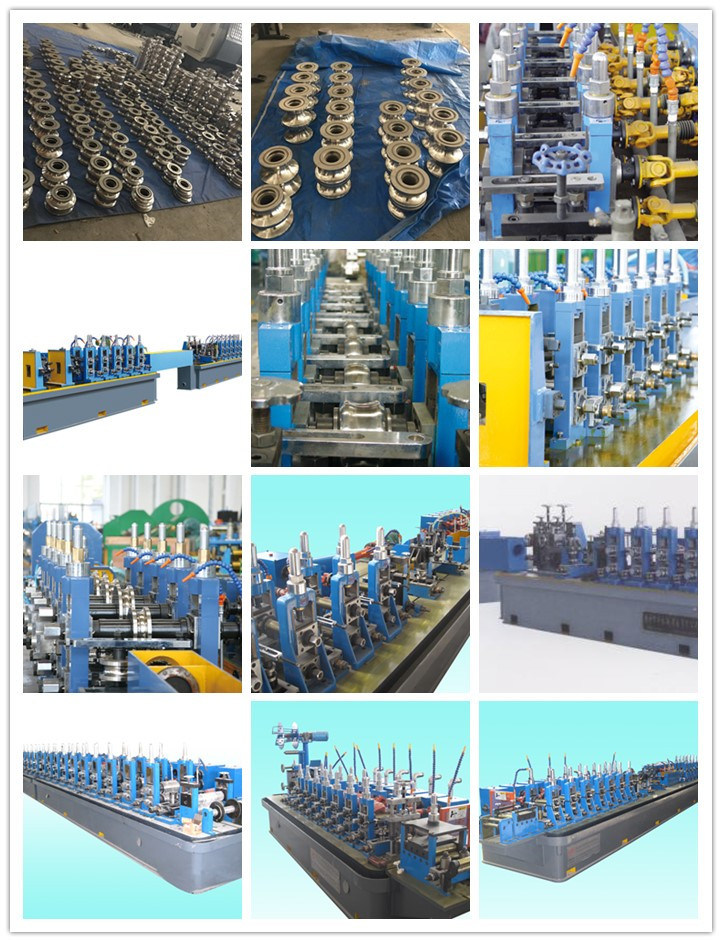

2: Our pipe production line installed in the world

My company have successfully supplied world-class products and service to over 30 countries and areas around the world, such as: Poland, Spain, Russia, Yugoslavia, Ukraine, Turkey, Egypt, Saudi Arabia, India, Vietnam, Malaysia, Thailand, the Philippines, Pakistan, kazakhstan, Ethiopia, etc.

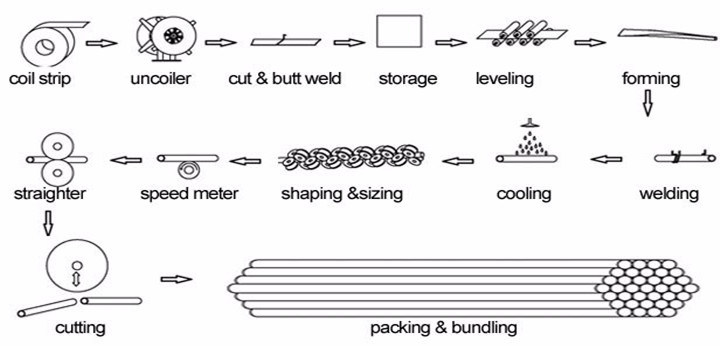

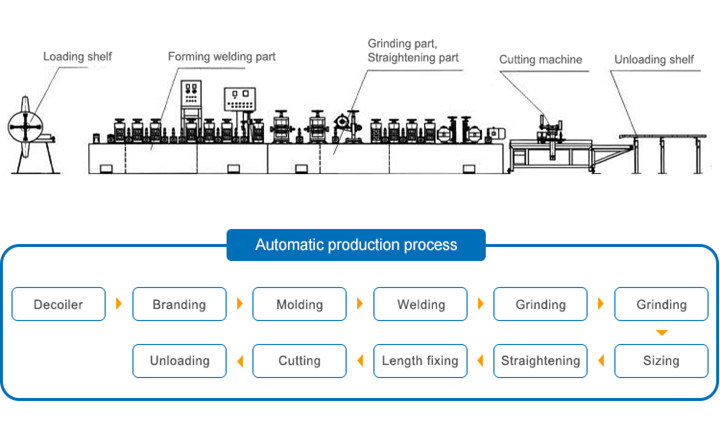

Flow Chart

Standard flow chart of 2018 new Welding Plant Stainless Steel Easy Operate Pipe Making Machine :

Step 1: Un-coiler

Function: support rolled plate and strip tension for erw pipe mill production line, by the frame, main shaft, increases of drum, brake.

There are 3 types: pneumatic, hydraulic and manual.

Step 2: Shear & butt-welding

Function: Shear the end of each strip coil, then welding them together, so that pipe making welding machine line can be continue production.

2 Types: Automatic & manual

Step 3: Vertical Accumulator

Function: storage strip to keep continue production for the machine to make metel tube.

Type: Vertical

Advantage: easy to operation, low investment. special for small size and light wall pipe

Disadvantage: less storage capacity, crease.

Step 4: Horizontal Accumulator

Function: storage strip to keep continue production for the Round Square Pipe Making Machine Production Line.

Type: Horizontal

Advantage: Large capacity.

Disadvantage: more expensive than vertical type

Step 5: Forming section

Function: forming the tube from stripAdvantage:

>Advanced forming technical

>One-stage molding platform

>Reliable quality gear box

>Siemens Beide motor

Step 6: High Frequency Welding

Function: Welding the pipe , different thickness & diameter, the power of the HF welding machine welder

Our advantage: We choose the China best welder: Sanyi brand.

Step 7: Sizing section of pipe making machine

Function: sizing the tube to precise size

Advantage:

>Advanced sizing technical

>One-stage molding platform

>Reliable quality gear box and Siemens Beide motor

>High precision, low error of the pipe size

Step 8: Flying saw

Function:cutting the tube mill line tube to right length.Advantage: easy to operation, low investment.

Disadvantage: loud, cutting section generates burr.

Step 9: Cold saw cutting of erw tube mill line

Function:cutting the tube to right length.

Advantage: No noise, no burr cutting precision and cross section .

Disadvantage: the price is 4 times of ordinary flying saw.

Step 10: Run Out Table.

Function: run out the pipe, packing the pipe for tube making machine

Type: Automatic or manual

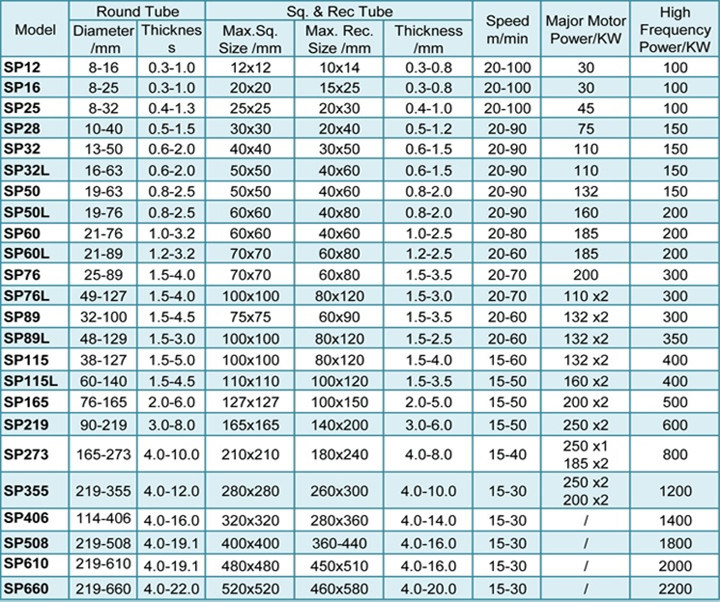

Below is our standard series of our steel pipe making machine., we also accept customized.

Packing & Delivery

Package by plywood case, Load in containers, and Shipping by Sea/ Truck / Train.

Our factory regards "reasonable prices, efficient production time and good after sales services" as our tenet.We hope to cooperate with more customers for mutual development and benefits. We welcome potential client to contact us.

We warmly welcome you to visit our factory!

We are looking forward to forming successful business relationships with new clients around the world in the future.

China

China