FRP yarn winding machine/FRP winding production line/fiber glass Pipe Production Line

FRP equipment /GRP FRP pipe machine/FRP equipment pipe equipment/FRP tank Machinery

Equipments/Pultruded FRP Equipment/FRP pipe Testing Equipmen/frp pipe equipment

/FRP rebar equipment/GRP machine/frp winding machine/frp tank equipment/frp pipe

machine/frp mandrel/GRP production line/GRP mould

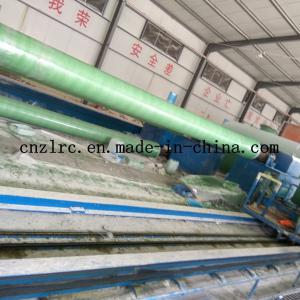

This production line is designed for producing FRP pipe with the following features:

High precision winding pattern

High productivity and low energy consumption

Simple installation and maintenance

Industrial computer control, easy in operation

Filament winding control system is developed by our company technicians, who combined characteristics of FRP products in composite industry.

As this production line adopts industrial computer control system, the user is able to set common winding programs once for all. It is mainly applied to the production of FRP pipe, FRP pipe with sand, FRP tank and so on.

You can choose the machine according to your demand.We can sell to you both the whole set machine and any part of it.We have our own R&D department,who design the control system and program,and improve the technology year by year.

| FWJS-1500 | FWJS-2600 | FWJS-3000 | |||

| Pipe diameter(mm) | DN300-DN1500 | DN300-DN2600 | DN300-DN3000 | |||

| Production length(mm) | ≤12300 | ≤12300 | ≤12300 | |||

| Winding angle range | 45°-90° | 45°-90° | 45°-90° | |||

| The way of adding sand | Both dry and wet | Both dry and wet | Both dry and wet | |||

| Max thickness of adding sand a time(mm) | ≤20 | ≤20 | ≤20 | |||

| Rotating speed of main shaft(r/min) | ≤85 | ≤85 | ≤85 | |||

| Max speed of pulling yarn(m/min) | ≤120 | ≤120 | ≤120 | |||

| Production capacity(kg/h) | 1800 | 2300 | 3200 | |||

| Total installed capacity(KW) | 110 | 120 | 120 | |||

| Areas covered by production line(length×width)m | 54x24 | 60x24 | 60x24 |

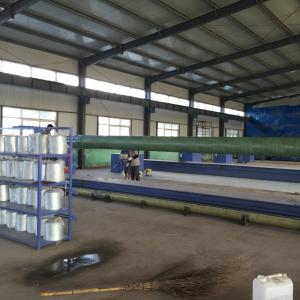

Basic allocation of frp pipe making machine

FRP pipe Liner making machine:

It is set up with Taida PLC numerical control device. The winding film, mat and gridding fabric can be controlled automatically by the tension bracket device which makes the lap joint is smooth and precise, so the artificial nonuniformity and waste phenomenon will be prevented.

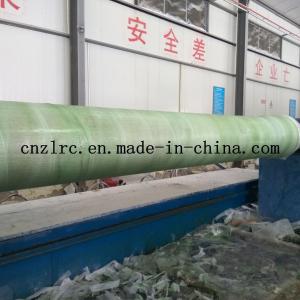

FRP pipe Winding machine:

The sand-adding method includes many modes: intermediate, bottom, dry, wet and dry-wet method. By being set up with automatic glue-supplying pumping station and mixer, ratio of sand inclusion is fully automatic and well-distributed, so the operation of the equipment is pretty convenient and accurately, low energy-consuming.

GRP pipe Curing station:

It includes open style and closed style. It's allocated with infrared heating system and the mould revolves automatically.

Fiberglass Demoulding machine:

It adopts hydraulic transmission and the movement is stable. The flexible distance of claw is long and the applying scope of diameter is wide. It saves the usage of mould-extracing loop so the operation is easier.

China

China