1- Introduction:

This production line can make different kinds fried snacks(such as rice crusts,chips bugles,pizza rolls,doritos etc )based on changing die moulds and manufacturing technique.The production process includes mixing,extruding,cutting,frying,flavoring and packing. The products are crispy and less oil.

2- Machines matrials: All the machines are made by 304 stainless.

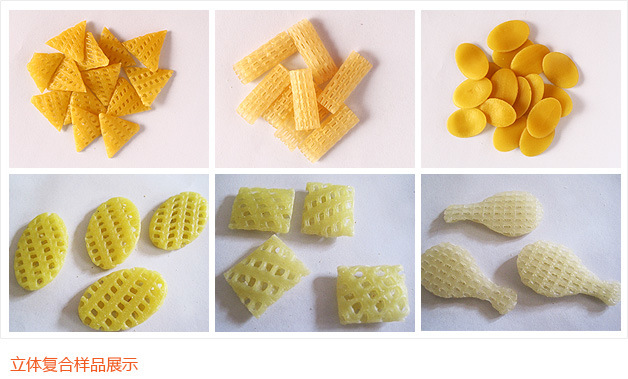

3- Products: By changing the mould of machine we can produce rice crust,French fries,bugles,fish cake,pizza rolls,crisp fruit,triangles,and other product.

4- Voltage in china: Three phases:380V/50Hz,Single phase:220V/50Hz,we can make it according to customers' Local voltage of different countries.

Samples for reference:

5- Snack machinery production line flow:

| NO | Machine | Application/Use |

| 1 | Mixer | Mixed raw materials |

| 2 | Screw-conveyor | Send the raw material to the extruder |

| 3 | Twin-screw extruder | Extruded the material by the twin screw |

| 4 | Cutter-QY | Cutter the chips or sticks products |

| 4' | Shaping cutter | Cutter the bugles,doritos or 3D snacks |

| 5 | Continuous fryer | Frying the product,making it more crispy |

| 6 | Deoiling machine | Deoiling the product |

| 7 | Flavoring line | Flavoring the product |

6- Snack machinery production line technical parameters:

| Modle | XBF65 | XBF70 |

| Installed power | 88kw | 126kw |

| Power consumption | 65kw | 82kw |

| Production capacity | 100-150kg/h | 200-260kg/h |

| Dimension(L*W*H) | 15*2*3m | 22*2*3m |

7- Snack machinery production line features:

1.Low power consumption.

2.Long life and cheap spare parts.

3.By changing the mould of the machine,you can produce ball,stick,ring,star,wheel,flower and heart-shaped products.

4.The whole production line is easy to operate,only need two or three workers to control the production line.

8- Detailed structure of twin-screw extruder:

The Twin-screw extruder is made up of the feeding system ,extruding system,cutting system,heating system,transmission system and controlling system.We will feed the material from the feeding machine and get the tissue state by inflating the material and the machine barrel must be high temperature,high pressure and high cutting.The material can be sterilized by the high temperature and high pressure.

9- Samples show:

10- Main characters of advanced new type XBF screw extruder

- Swiss Technology,made in China;

- PLC touch screen for Centralized ,accurate,convenient control

- Fully automatic control system for heating and circulated cooling accurately

- Direct transmission of motor and distribution box reduces energy loss.

- Imported bearing group with higher bearing capacity

- Equip with water injecting device on barrel to meet require of various raw material and quality.

- High-speed tool steel with hardness HRC≥62 to ensure a longer service life.

- Modular combination of screws at will to meet require of different raw material.

- Suspension type rotary cutter with bearing adjusting device to ensure quick,safe and accurate

- All barrels inlaid alloy sleeve, easy to replace and extend the life span of screw. All barrels inlaid cooling water through, spread around alloy sleeve, and can accurate constant temperature required

- All screw sleeves is kneading, ensure that not accumulate material. The screw is installed by blocks, and can be replaced optionally ratio to achieve requirements for product. Screw sleeve is installed by spline, and it is convenient and efficient. Quality of screw sleeve according to different prices is divided into: Cr12MoV, 38CrMoAl38, W6Mo5Cr4V2.

- Applied to make all kinds of extrusion products such as corn flakes , cereal snacks ,puff snacks ,wheaten snacks , 2d /3d snack pellets , pet food ,fish feed ,soya protein ,nutritiobal powder ,modified starch and so on.

11- Machine material details

- Machine shield : 201 ss / 304 ss as required

- Parts contact with food : 201 ss / 304 ss as required

- Screw / barrel and cutter of the extruder : special alloy to bear high temp and pressure

- Main motor: Siemens brand

- Touch screen : Wenview brand

- Miniature circuit breaker : ABB brand

- Alternating current contactor: ABB brand

- Thermal Relay: ABB brand

- Moulded case circuit brake : CHNT brand

- Small relay: Weidmuller brand

- Inverter: Delta brand

- PLC system: Delta brand

- Burner: Baltur brand

- Bearing : NSK/ SKF brand

• Inside package is plastic film, outside is wooden or plywood case

(Plant-based vegetable textured soy protein making machine based on the customers' need).

• Only plastic film nude packing with wooden pallet.

• We can supply fumigation package and certificate.

• Shipping, train, express or upon clients' demands.

13- Our services:

1. Free consultation service before, during, and after sales;

2. Free project planning and design services;

3. Free debugging of equipment until everything is functional;

4. Free long distance shipping management from seller's factory to named place by buyer;

5. Free maintenance and operating training personally;

6. Free new production techniques and formulas;

7. Provide 1 year complete warranty and life-time maintenance service;

14- FAQ:

1. Are you snack food making machine manufacturer or trader?

A: Certainly we are snack food making machine manufacturer. Welcome to visit us to check it !

2. Do you supply formula of snack food made by snack food extruder to buyers?

A: Yes, we supply free formula to buyers.

3. What kind of fuels we can choose during the production?

A: You can choose gas, diesel, electricity, steam as fuels, but please tell us when you ask for quotation.

4. How much area the whole making machine production line needs?

A: The best way is telling us your workshop area, then we will draw a draft for you to ensure the rational use of your space.

5. If the power supply is not 3ph 380V 50HZ, could you offer the suitable machine?

A: Yes, we can offer the suitable machine according to your power supply, for example 3ph 380V 60HZ, 3ph 415V 60 HZ, 3ph 220V 60HZ and so on.

6. Do you supply packing machine?

A: We have long-term cooperation packing machine supplier, we will help to contact them.

China

China