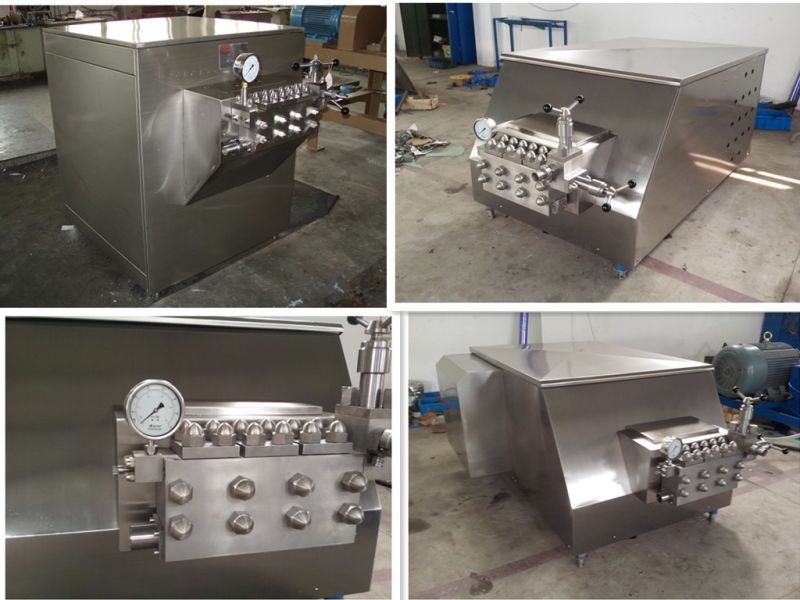

Homogenization is the mechanical process where raw materials are put under high pressure and broken down into smaller particles.

This equipment can be used widely in production, research and technical development of food, milk extract, drink, pharmacy, fine chemical, biotechnology and other fields.

Many kinds of material such as milk or bean milk can be homogenized under high pressure to considerably thin the fat balls in the milk liquid, which makes the products be easy to be digested and absorbed, and improve the edibleness.

This equipment can be used in the production of ice cream to improve the thinness and fraction void of liquid material.

Main Characteristics:

|

| APPLICATION | |

| Food and Drink | Juice ,Condiments, Peanut oil, Protein powder, etc. |

| Dairy : Milk | Milk, ice cream, yogurt, cheese, butter, etc. |

| Pharmaceutical | Antibiotics,Intra lipid, Antacids, etc. |

| Chemical | Lubricants, disinfectants, paints, dyes, etc. |

| Other | Cell disruption, yeast, cosmetics. |

1.Provide for equipment inspection certificate and manual, to ensure that users properly install and use.

2.Equipment to reach the destination, the company will send engineers to guide installation and

commissioning and customer training until satisfied.

3. The warranty period will be free to customers wearing accessories, after one year warranty period, our

company to provide parts at cost.

4.we provide lifelong maintenance service, including if necessary, to send engineers to the customer at the

service.

Shanghai Nancheng Machinery Co., Ltd. is a professional manufacturer dedicated to research, development, manufacture and sale of all kinds of beverage and foodstuff machinery.

Having the rich experience of more than 20 years in foodstuff & beverage machinery field, we can help customers design, manufacture, install and operate the turn-key project for mineral water, pure water, carbonated drink, fruit juice, milk, yogurt, cheese and ice cream production lines etc.

Our main products include water treatment systems, bottle blowing machine, RO systems,3-in-1 mono block filling machine, coil, plate, tubular UHT sterilizers, homogenizer, ink jet printer, liquid packing machine, shrink labeling machine, all kinds of tanks, ice cream machine,popcorn machine,bakery machine, foodstuff machine, etc.

With the good reputation and fame among the loyal customer, our products have been sold and distributed to over thirty provinces and cities in China, exported to more than 85 countries and areas throughout the world. Upholding the idea of providing customer with "Innovative solution, Reliable Quality and Responsible Service", we aim to offer more reliable and flexible machines that are easily adaptable to market developments and future technology.

Our company has rich experience to help customers to establish the different production lines for different use, for example. we can arrange technical staff to help customer set up whole production line for mineral water, pure water,coca-cola, milk, juice and vinegar,oil, we are profession for making it. If anyone who is interested in such field wants to buy the whole equipments and machines, pls contact us freely.

We warmly welcome customer to visit our factory at any time,you will see the machine working and running conditon in our factory!

Responsible Man(General Manager):Jason

Cel.Phone:0086-15221595986

Tel.Phone:0086-21-31600114

China

China