Introduction:

Prepollent all welded plate heat exchanger is well suited for applications involving high temperature and high pressure with relatively clean media. The fully welded design makes this type of heat exchanger is well used above all in the oil and gas industry, the chemical industry as well as in the petrochemical sector. The media can also be very corrosive.

• Oil industry

• Chemical industry

• Solvent recovery processes

• Gas dehydration plants

• Batch reactors

• Refrigeration duties

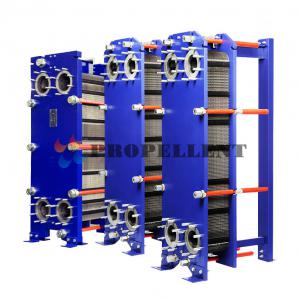

| Welded Plate heat exchanger PL-W65A | |

| Technical specifications | |

| Design temperature | 350ºC |

| Design pressure | 35 bar |

| Plate thickness | 0.5 mm-1.0 mm |

Materials | |

| Heat transfer plates | Stainless steel - 304/304L, 316/316L, 254 Titanium Hastelloy C-276 |

| Frame | Mild steel. High temperature painted |

Dimensions | |

| Height | 1037 mm |

| Width | 462 mm |

| Length | 400 mm / 1250 mm |

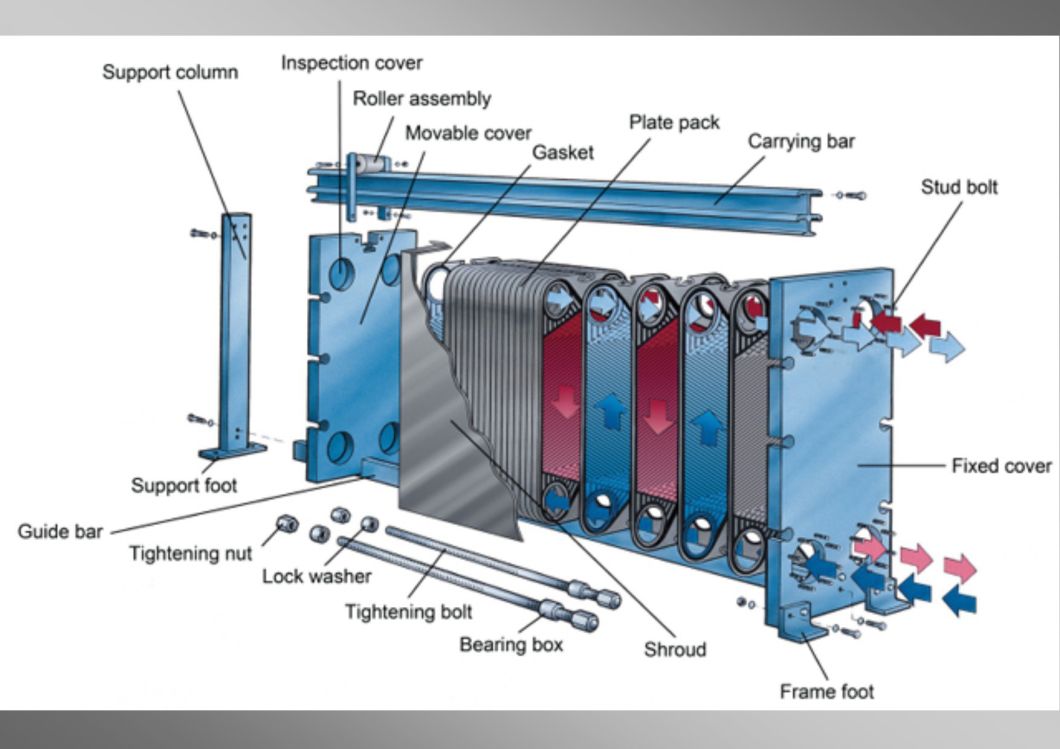

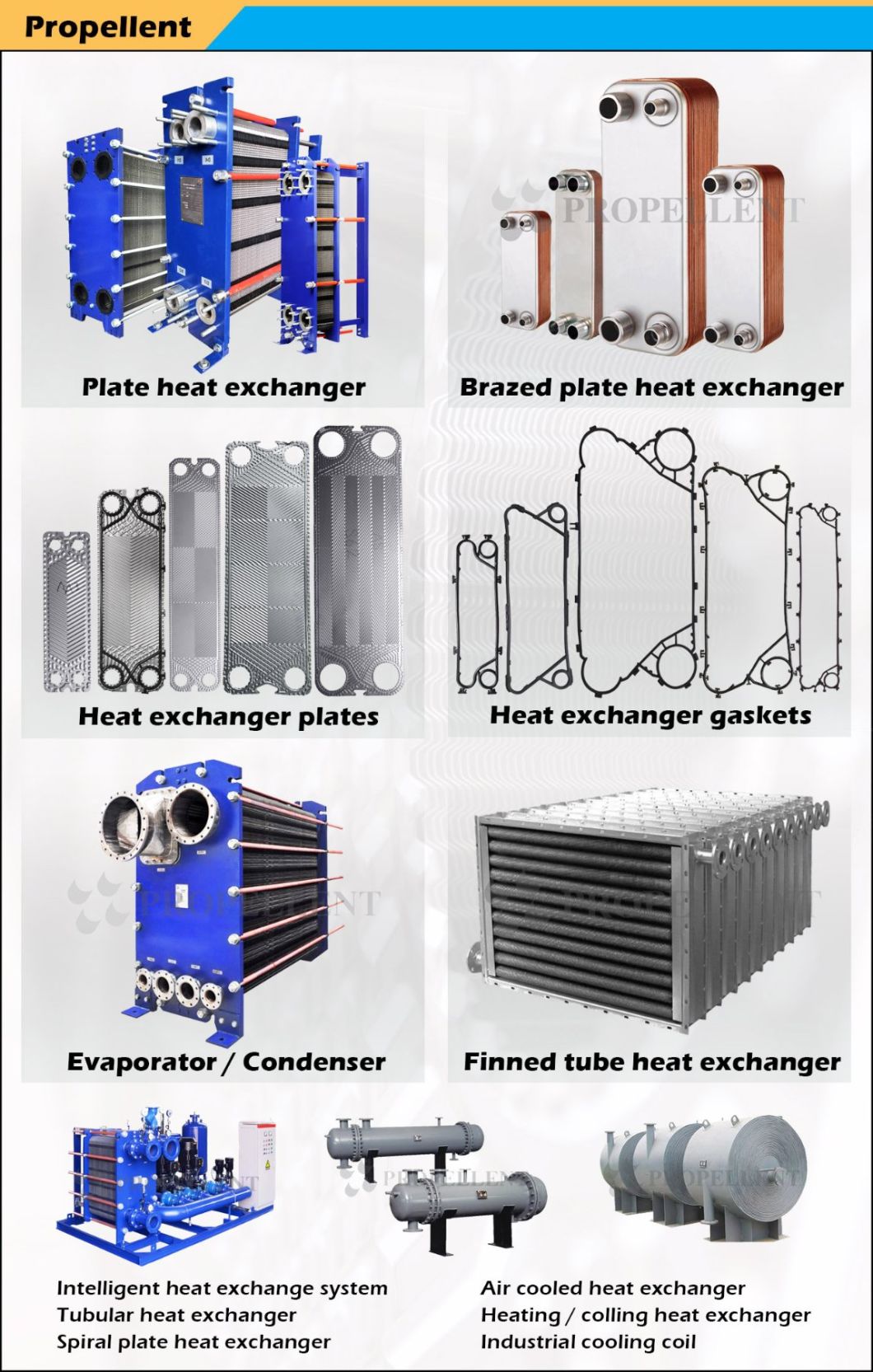

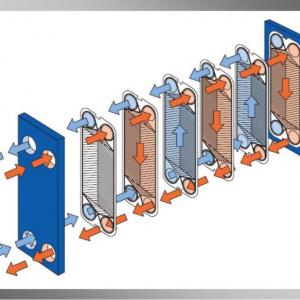

Plate heat exchanger structure

Propellent, as the promoter and one of the leaders of effective heat exchanger technology, has been designing and manufacturing heat exchangers for decades of years. Propellent offers a full range of heat exchangers and heat transfer services in all type of industries. To achieve high efficiency at low operating costs, greater application possibilities at a lower investment costs. Customized solutions are provided to match the customers' requirements.

We also offer abundant types of replacement parts for plate heat exchangers, these spare parts apply to international brands in all direction, such as GEA, APV, Sondex, Tranter, Vicarb, Hisaka, API etc, to meet our clients' demand all over the world.

Our factory

Thanks for your visiting propellent heat exchangers.

If you have any questions, kindly please feel free to contact us.

China

China