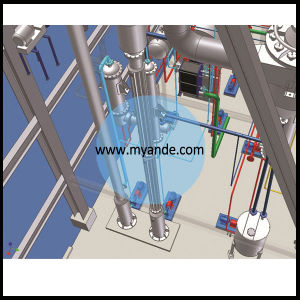

Brief Introduction

Myande MZFJ Range Multi-effect Film Falling Evaporators are widely used in evaporation and concentration of starch syrup, zymotic liquid, starch steeping solution, dairy products, beverage, high concentration organic waste water, and chemical products. Major technical features include high energy efficiency, short heating time and high concentration proportion. With high flexibility, MZFJ Multi-effect Film Falling Evaporators are capable of being combined into bi-effect, triple-effect, quadruple-effect and corn steeping solution evaporation systems according to process requirements. Both live steam and exhaust waste hot steam can be used as heat source. As material falls from top to the bottom in the form of helical film, it conducts heat exchange directly with steam outside of tubes. Temperature difference is consistent and secondary steam is recycled to reduce steam consumption.

Description of Product:

1. Major technical features include high energy efficiency, short heating time and high concentration proportion.

2. With high flexibility, MZFJ Multi-effect Film Falling Evaporators are capable of being combined into bi-effect, triple-effect, quadruple-effect and corn steeping solution evaporation systems according to process requirements.

3. Both live steam and exhaust waste hot steam can be used as heat source.

4. As material falls from top to the bottom in the form of helical film, it conducts heat exchange directly with steam outside of tubes.

5. Temperature difference is consistent and secondary steam is recycled to reduce steam consumption.

China

China