Hello I am Hamed Valipour from Iran I am a repairman of a company that has bought a grating device with accessories from you. A heating and cooling system or the same chiller for the grating device has been sent to us and the model of the grating device o

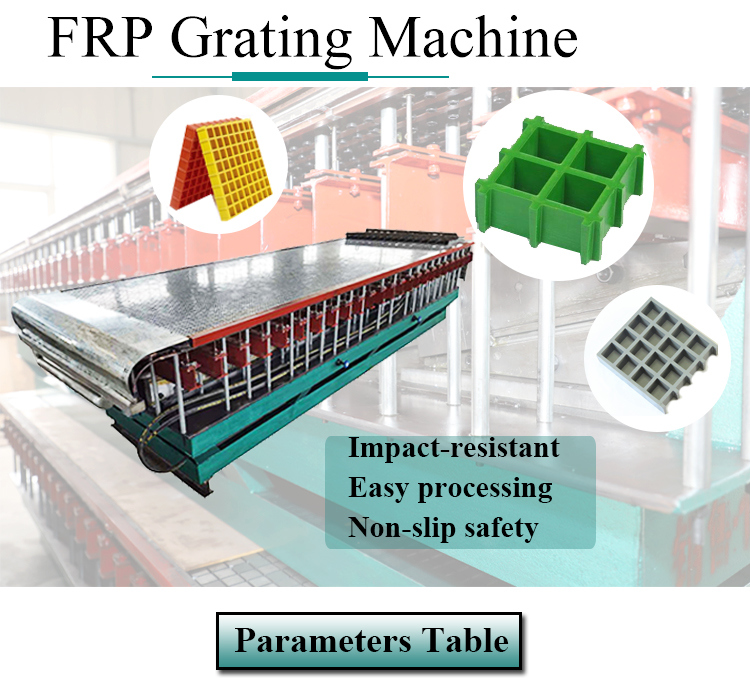

We are professional FRP grating and grating machine manufacturer with more than 10 years of experience, all of our productions are strictly run under ISO 9001 Quality Control System. Our grating machine has the advantage of high quality and acceptable price

Working principle:

2.2kw motor, 10t hydraulic force, Water heating or electric heating,

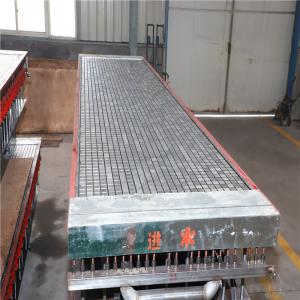

Produce process:

Material mixing- slip FRP materials-mold- solidify- mold release

Welcome to visit our factory. We can show you the produce process.

Specifications:

Weight: 3.5t, 4.5t

Material: 45#steel

Automatic operation

fast heating

Strong operability

Convenient installation

Easy to operate, install and maintain

Accessories:

Hydraulic lift, pump

Resin mixer

Polishing machine

Cutting machine

Resin Bucket

The advantages of grating machine that it produce:

Light weight

Anticorrosive and burn resistant

Non-slip

Insulated

Impact resistance

Aging resistance

Easy to cut

Good appearance

Long service life

Good mechanical property.

Common size for your reference

Item no. | Height(mm) | Mesh Size (mm) | Standard Panel Sizes(mm) | Bar Thickness (top/bottom-mm) | Open Area | Weight (kg/m2) |

| 1 | 13 | 50.8×50.8 | 3660×1220 | 6.4 / 5.4 | 76% | 5.5 |

| 2 | 15 | 25.4×25.4 / 50.8×50.8 | 3660×1220 | 6.2 / 5 | 57% | 7.2 |

| 3 | 15 | 38.1×38.1 | 3660×1225 | 6.3 / 5.2 | 69 | 6.5 |

| 4 | 15 | 20×20 / 40×40 | 4047×1247 | 6.35 / 5.3 | 47 | 11.5 |

| 5 | 20 | 38.1×38.1 | 3665×1225 | 6.3 / 5 | 69 | 9.3 |

| 6 | 20 | 12.8×12.8×12.8 / 38.5×38.5 | 3434×970 | 7.2 / 6.4 | 27 | 18.5 |

| 7 | 25 | 38.1×38.1 | 3665×1225 | 6.35 / 5 | 69 | 12.3 |

| 8 | 25 | 40×40 | 4047×1007 | 6.35 / 5 | 70 | 12.2 |

| 9 | 25 | 19×19 / 38×38 | 4005×1220 | 6.4 / 5 | 44 | 15.5 |

| 10 | 25 | 25×100(Bearing bars to run width direction) | 3007×1009 | 9.4 / 8(length) 6.4 / 5(width) | 67 | 13.8 |

| 11 | 25 | 25.4×101.6(Bearing bars to run width direction) | 3660×1220 | 7 / 5 | 67 | 13 |

| 12 | 25 | 101.6×25.4(Bearing bars to run length direction) | 3665×1225 | 7 / 5 | 67 | 13.1 |

| 13 | 30 | 38.1×38.1 | 4008×1525 | 6.6 / 5 | 68 | 14.6 |

| 14 | 30 | 40×40 | 4047×1007 | 6.6 / 5 | 69 | 14.2 |

| 15 | 30 | 20×20 / 40×40 | 4047×1247 | 7 / 5 | 42 | 18.1 |

| 16 | 30 | 12.7×12.7×12.7 / 38×38 | 4040×1220 | 7 / 5 | 30 | 23.5 |

| 17 | 30 | 26×26 / 52×52 | 4011×1150 | 6.5/5 | 56 | 13.6 |

| 18 | 38 | 38.1×38.1 | 3969×1525 | 7 / 5 | 66 | 19.2 |

| 19 | 38 | 40×40 | 4047×1007 | 7 / 5 | 67 | 18.8 |

| 20 | 38 | 152.4×25.4(Bearing bars to run length direction) | 3665×1226 | 7 / 5(length) 9 / 7(width) | 68 | 20.4 |

| 21 | 38 | 101.6×38.1(Bearing bars to run length direction) | 3660×1220 | 7 / 5 | 76 | 14.5 |

| 22 | 38 | 19×19 / 38.1×38.1 | 4045×1220 | 7 / 5 | 40 | 23.5 |

| 23 | 38 | 20×20 / 40×40 | 4047×1247 | 7 / 5 | 42 | 22 |

| 24 | 40 | 40×40 | 4047×1247 | 7 / 5 | 67 | 20 |

| 25 | 40 | 220×60 | 2207×1507 | 7 / 5 | 85 | 9.5 |

| 26 | 40 | 20×20 / 40×40 | 4047×1207 | 7 / 5 | 42 | 23.7 |

| 27 | 50 | 50.7×50.7 | 3660×1225 | 8.3 / 5 | 69 | 21.5 |

| 28 | 50 | 50.7×50.7 | 3660×1225 | 8.8 / 5 | 68% | 23.5 |

| 29 | 50 | 25.35×25.35 / 50.7×50.7 | 3660×1220 | 8 / 6 | 47% | 26 |

| 30 | 50 | 152.4×38.1(Bearing bars to run length direction) | 3660×1220 | 9 / 7 | 72% | 20.8 |

| 31 | 50 | 38.1×38.1 | 3665×1225 | 11.5 / 9 | 48 | 40.5 |

| 32 | 63 | 38.1×38.1 | 3660×1220 | 9 / 5.8 | 58% | 38.5 |

| 33 | 63 | 38.1×38.1 | 3670×1230 | 12 / 9 | 46% | 52 |

| L×W×H(mm×mm×mm) | Center Distance(mm×mm) | Tendons relief(mm) | Module(mm) |

| 1220×3660×38 | 38.1×38.1 | 7 | 38.5-41 |

| 1220×3660×30 | 38.1×38.1 | 7 | 30.5-32 |

| 1220×3660×25 | 38.1×38.1 | 6.8 | 25.5-27 |

| 1220×3660×50 | 50.7×50.7 | 7.5 | 50.5-52 |

| 1000×4038×38 | 38.1×38.1 | 7 | 38.5-41 |

| 1000×4038×25 | 38.1×38.1 | 6.8 | 25.5-27 |

We have manufactured FRP grating machine for many years. And our machine has been exported to many countries. Satisfying customer's demand is our responsibility and we will try our best to satisfy customers by our high quality, competitive price and good service.

If you by our machine, we train you free in factory. Besides the grating machine, we also offer you the auxiliary equipment, such as polishing machine, boiler, and resin tank and so on.

The machine fabrication, the modules with chrome, to protect the modules surface.

We have professional team to produce the best quality machine for our customers.

Cautions:

Before use the new mold clean up oil stains and other dirt inside the mold.Before use the mold please check if the screws loose or not. If loose, please fasten in time.Keep the mold slide adequate oil, prohibit knocking the I beam steel with hammer. Spray the demoulding agent three times, spray the agent after curing the last spray.After producing 3-4 grating sheets spray the demolding agent to the mold. Produce after the agent drying. In the following production please spray the demolding agent periodically according to the actual conditions.

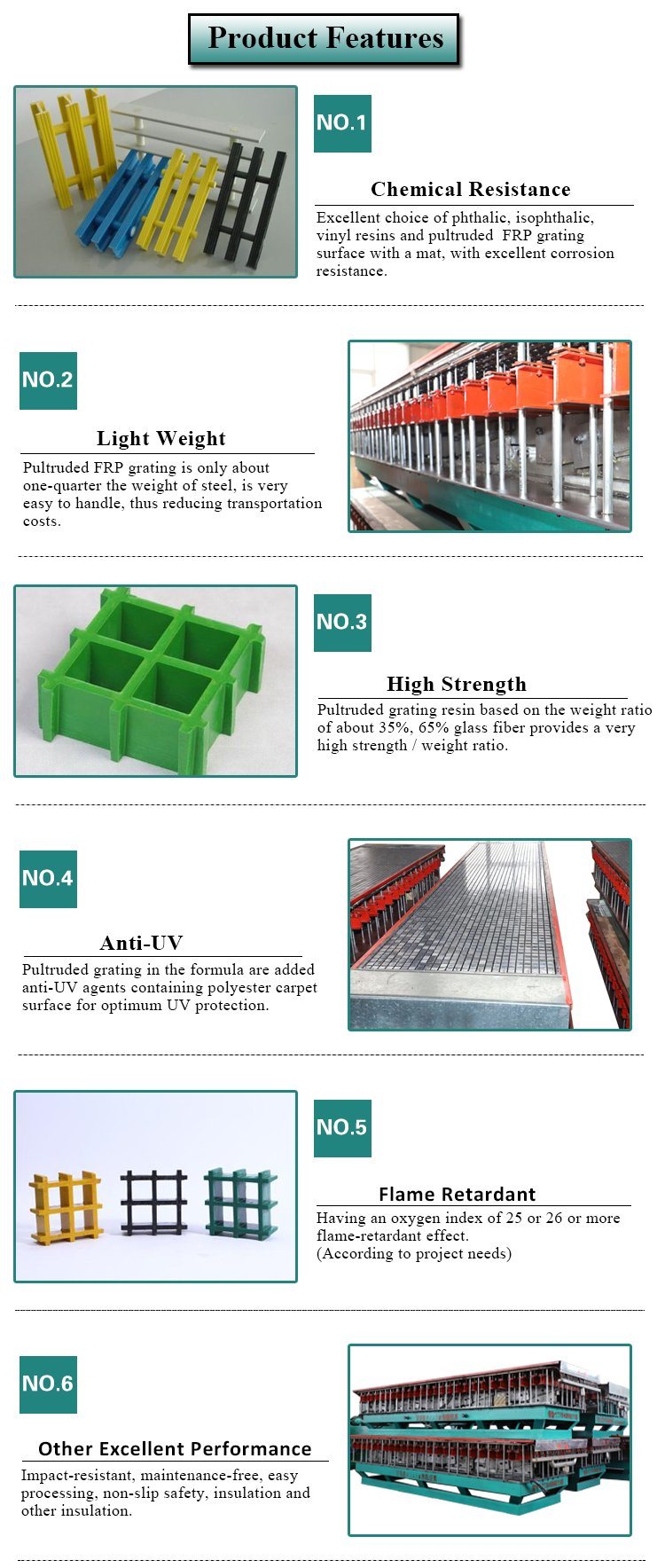

FRP Grating is one kind of new composite material, made of different resins reinforced with fiberglass, by molded technology. It has excellent properties as follows:

1) FRP Grating is recommended when corrosion protection and safety are your goal.

2) Expansion and contraction is 24% and 50% less than aluminum and steel, providing greater dimensional stability.

3) Superior durability to Stainless Steel, Aluminum, and Galvanized Gratings, especially in highly corrosive environments.

4) 50% higher tensile strength than hot rolled steel and better impact resistance.

5) All gratings available in yellow, green or grey, other colors available upon requests.

6) Has a good economic benefit.

Characteristics

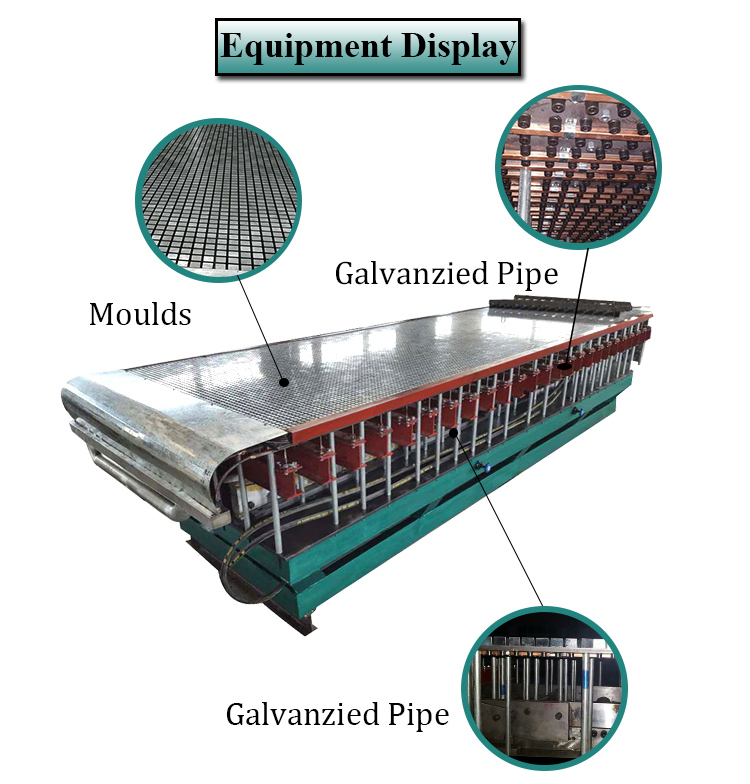

1.Ejector rod lifting device is two cylinders to parallel advance, smooth, no waving.

2. Stripping plate and stripping beam adopt elasticity connection, go up and down is parallel and steady.

3. The module using delicate 45# steel, grinding, polishing and the surface is plating. It has antiseptic function, smooth and easy to Detmold.

4.Ejector rod can go up and down along with lifting device, easy to change and easy maintenance.

5. Ejector rod is made from steel parts grinding, surface smooth, firmness and wear resistance.

6.Hydraulic station adopt hydraulic parts made by Sino-Japanese joint venture, it is long-life and durable

7.Mould temperature rise and drop are achieved by rectangular copper pipe, which have large contact area with template, temperature rise and drop fastly,and it can heat the mould top surface. In terms of the four borders of the mould, it is anti-corrosion and durable. Joint adopt stainless soft joint, joint destuffing is convenience, anti-corrosion and durable.

8. Hot and cold water injection use high-powered water pump, pipe connections in parallel, so the heating and cooling speed are both fast.

9. There is protective equipment on the mould to avoid the resin leakage.

10. The mould adopts the screw on the bottom to lockup, it is easy to adjust and change.

Shipping

Our service

Researches and development team by knowing the importance of the FRP usage in industry and construction, have successfully conducting different researches and studies projects. At the present, it has several government- supported projects available.

Design and engineering services has been given idea from customers, and make out the things you imaged. Specially developing on new machinery.

Installation and construction team is experienced with installation, commissioning and training service at customer's factory. In this way, the customer is able to handle management of equipment themselves soon.

Maintenance service is applied when customer can't solve problem themselves. Mainly at equipment, software, tools…etc.

Technical support is the most importance in production. As long as frp developing, new and advanced process, material, equipments appeared. We are giving the eyes on the world frp relative news and supply customer advanced service.

Packages

| Packaging | 1.Plastic film |

| 2.Plastic pallet with carton | |

| 3,wooden pallet with wooden case | |

| 4.According to customer's requirement | |

| Delivery | 1. Stock size 10-15 working days |

| 2.Custom size25-30 working days |

Please do not hesitate to contact us if you have any questions. We will try our best to serve you. It is our great pleasure to invite you all to visit our company and factory.

FAQ:

1. Q: Are you factory?

A: Yes, we are factory that produces frp products and machines.

2. Q: Can you make the frp grating machine by customer's requests?

A: Yes, we can customize the machine for you.

3. Q: What is the warranty?

A: The warranty is one year. Technical support all the time.

4. Q: What is the delivery time?

A: Usually 15-25 days after prepayment according to the order quantity.

5. Q: Why choose you?

A: We can provide you the good quality machine with best price and excellent service.

China

China