Design and Manufacturing according to ATEX, CE Standard

Introduction

TDF Fork Density Meter could apply the on-line density testing. It could be applied in the product process controlling based on the basic parameters of density, or the mass controlling system as the solid percentage or the concentration for references.

Typical Industries include petroleum chemical industry, wine industry, food industry, pharmaceutical industry and mineral processing, (for example clay, Carbonate Carbon, Silicate, etc.). The Fork Density Meters are applied in the pipeline detection of the multiple medium of the industries listed above, density testing of the stirred mixture, the reaction kettle end monitoring, and the separator interface detection.

Characteristics

TDF density meter fully integrates digital density measurement for monitoring and control; Capable of direct insertion into large bore pipe work applications, substantially reducing the installation cost compared to flow through devices.

General Technical Parameters (For Details, please contact Tosilon)

Density Range Calibration Range

0.5-2.5 g /cc (500 2500 kg/m3) 0.8-1.2 g /cc (800 1200 kg/m3)

Accuracy Repeatability

± 0.002 g /cc (± 2 kg/m3) ± 0.0002 g /cc (± 0.2 kg/m3)

Temperature Range (Process) Pressure Rating

-20 ~ +150 Degree Celsius (0C) 10MPa ~ 20MPa

Viscosity Range Temperature Effect

0 20000 cP Less than 0.1 kg/m3/0C (After Calibration)

Impact from Pressure Built-in Temperature Sensor

Negligible PT100

Wetted Parts Tine Finish

Stainless Steel 316L/ HC Hastelloy Standard , PFA Coated, or Electro-Polished

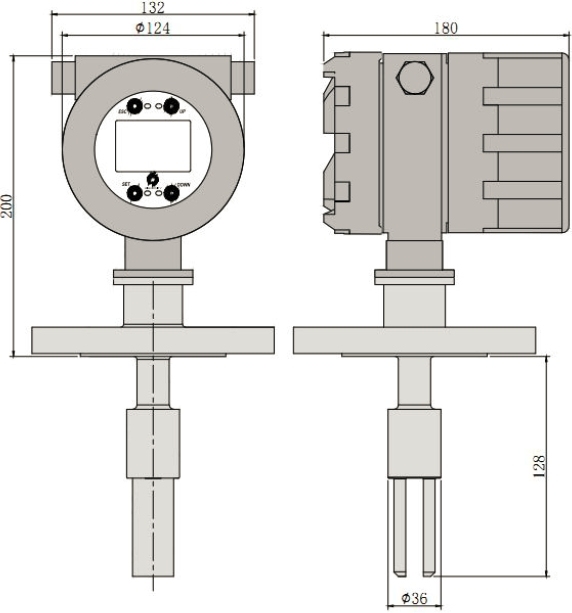

Outline Structure

| Density Range | 0.5 - 2.5 g /cc (500 - 2500 kg/m3) |

| Calibration Range | 0.8 - 1.2 g /cc (800 - 1200 kg/m3) |

| Accuracy | ±0.002 g /cc (± 2 kg/m3) |

| Repeatability | ±0.0002 g /cc (± 0.2 kg/m3) |

| Temperature Range (Process) | -20 ~ +150 Degree Celsius ( 0 C) |

| Pressure Rating | 10MPa ~ 20MPa |

| Viscosity Range | 0 - 20000 cP |

China

China