MQL fluid bed air grinder

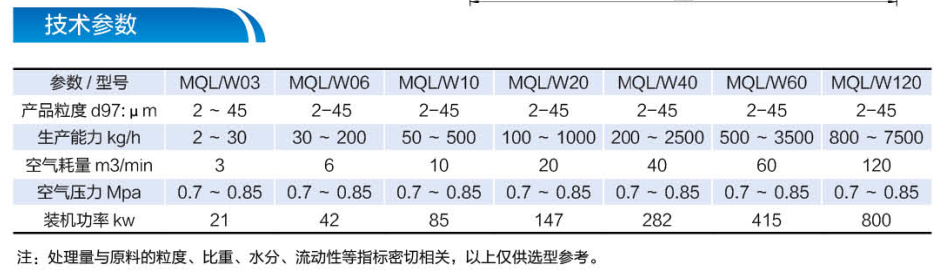

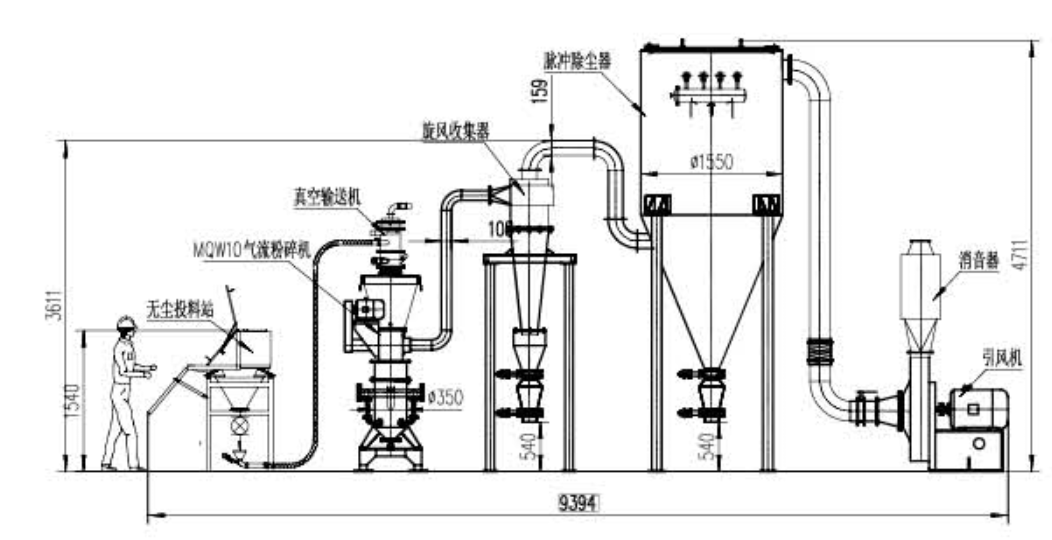

The air grinder is completed with cyclone separator, duster, draught fan to a full grinding system. the compressed air will be jet to the grinding chamber through laval nozzle after filtering and drying, the material will be crashed, grinded by the point of the high-pressure air. The material will be token by the upper flow to sorting part, by the powerful centrifugal force, the crude and fine powder will be separated, the fine powder will pass the sorting wheel to the cyclone separator and duster, the crude powder to grinding part and continue grinded.

Suitable for the material under Moh's hardness under 9 by dry method, especially for high hardness, high purity and high additive valve.

Character

Fineness D97, can be adjusted in 2-150 um, good shape, tight powder distribution

Low temperature non-medium grinding, suitable for heat sensitive, low melting point, sugary and volatility material.

The grinding is finished by crashing, comparing with the other grinder by blade or hammer, the equipment is wearing resistant, to make high purity.

Can be used with multiple grade sorter, producing different fineness the same time.

The equipment is easy disassembled and washed, the inner wall is sooth.

The system is sealed processing, small dust, low noise, the process is clean and environmental protection.

The control system is by program control, easy operation.

China

China