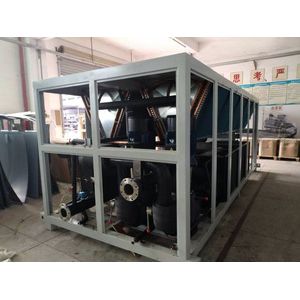

250 Kw 100Hp Industrial Air Cooled Screw Water Chiller

Anyda as the china water chiller manufacturer, have gradually produced Industrial Chiller,Water Chiller,Air Cooler,Oil Chiller,Low Temperature Chillers,Hot Water Chiller, Heat Pumps and Central Air Conditioner which are widely applied to plastic & rubber machinery, daily-use chemical, textile, general machinery, laser machinery, LCD and PCB industry, electroplating, equipments of laboratory, food, pharmacy, etc .

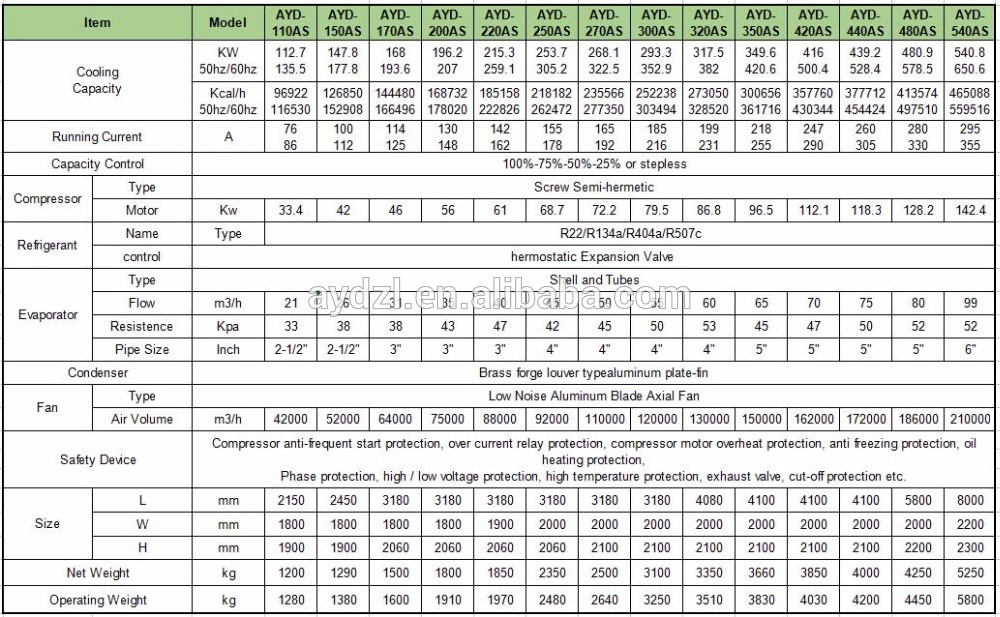

250Kw 100Hp Industrial Air Cooled Water Chiller Parameters:

| Item | Specifications | |

| Cooling Capacity | Model | AYD-250AS |

| kw/h | 250 | |

| Power Input | kw | 80 |

| Outlet Temp | degree | 7 |

| Power Supply | 380V-3N-50HZ | |

| Refrigerant | R407C | |

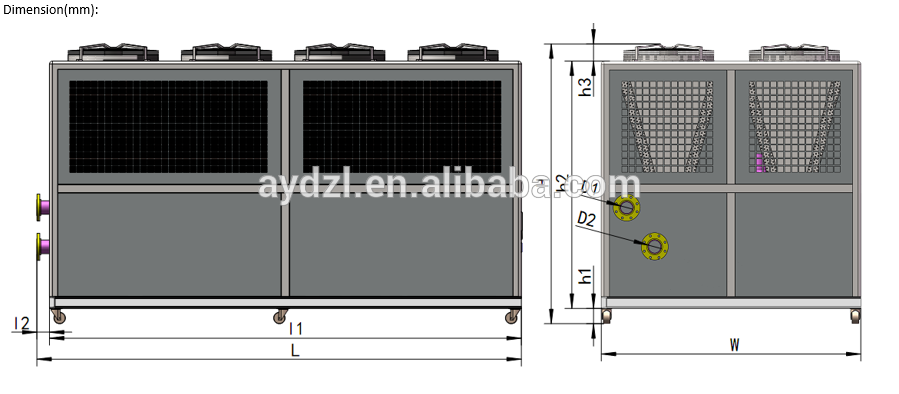

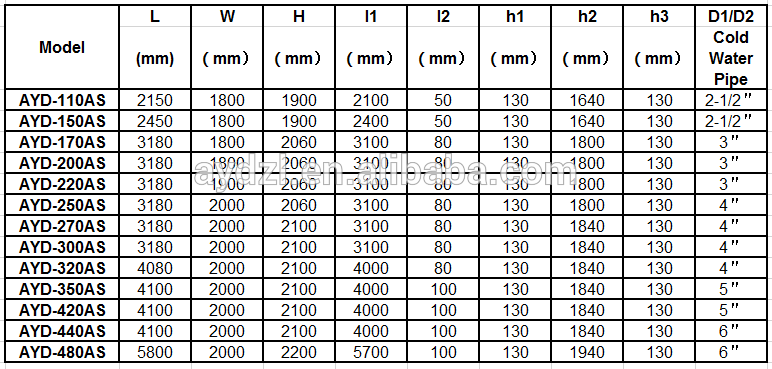

| Dimension(L*W*H) | mm | 4180*1900*2060 |

| Compressor | Type | semi-hermetic screw |

| Power(kw) | 70.3 | |

| Condenser | Type | Finned |

| Fan Power(kw) | 8.8 | |

| Air Volume(m3/h) | 108000 | |

| Evaporator | Type | SST plate heat exchanger |

| Pipe Size(") | 4 | |

| Flow(m3/h) | 43 | |

| Protector Device | 1.Phase protector 2.Overload protector 3.High/low voltage protector 4.Coil overheat protector 5.Anti-freeze protector | |

Main Features

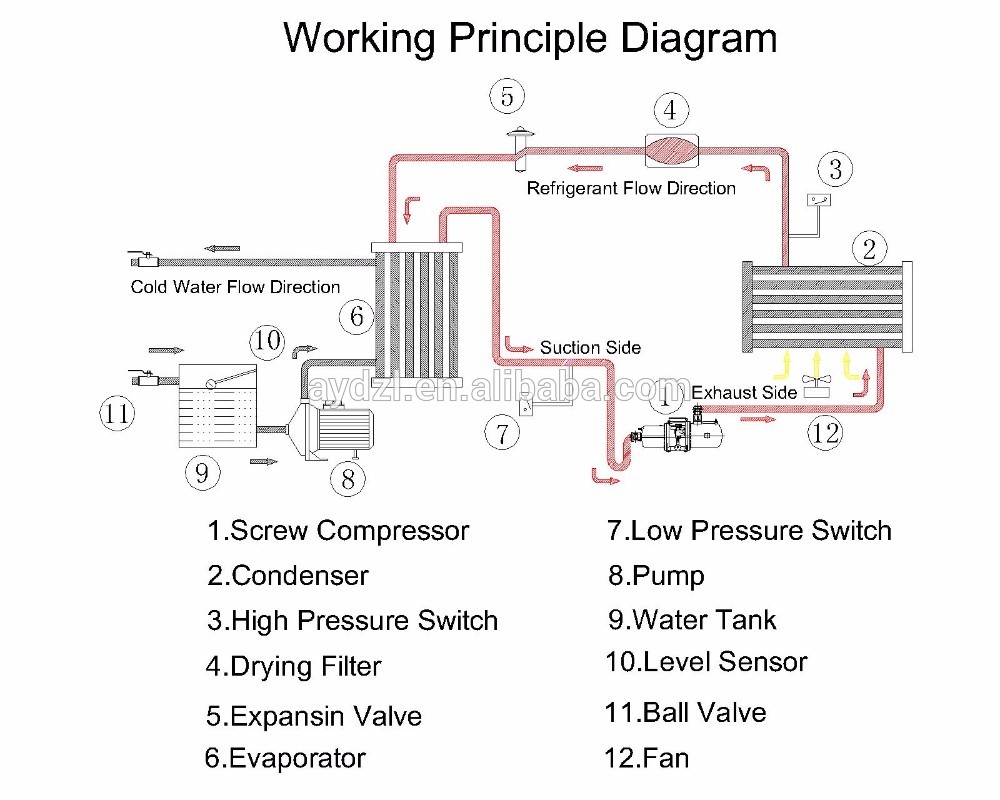

1.Packaged air cooled screw water chiller unit adopt the semi-hermetic screw compressor(like Habell,Bitzer), and operate credibility, high efficiency, easy to maintain, exact volume control, a wide range of application. The system adopts the latest asymmetric rotor profile. Build-in pressure drop lubricant to system with low vibrations, sound emissionshigh sealing performance.

2.Packaged air cooled screw water chiller unit 's human machine interface configures a full touch screen, which enables automatic control and accurate monitoring. The advantages of unit: water-proof,dust-proof, corrosion resistant, long life. Step or stepless capacity control, the unit ensure that it bring into the most energy-saving effective in any load conditions.

3.Packaged air cooled screw water chiller unit due to use heat copper tube and high efficiency compressor with high effective thermal expansion current-saving device, the unit will operate in stability, longer and effectively.

4.Packaged air cooled screw water chiller unit adopts a reliable safety protection device: to prevent compressor starting frequently, over-current protection, overheat of motor protection, prevent freezing, sight glass in liquid, oil heating protection, phase protection, HV/LV protection, discharge high-temperature protection, safety value, soluble clock, water shut-off protection, and so on.

Machine Parts

Name: Compressor

Brand: Hanbell/Bitzer

Name: Condenser,Evaporator

Brand: Anyda

Name: Control Panel

Brand: Punp/Siemens

Name: Electrical Parts

Brand: LG/Schneider

| Packaging | |

| Size | 3300 (L) * 2000 (W) * 2100 (H) |

| Weight | 2200kg |

| Packaging Details | The normal package is wooden box(Size: L*W*H). If export to european countries,the wooden box will be fumigated.If container is too tigher,we will use pe film for packing or pack it according to customers special request. |

China

China