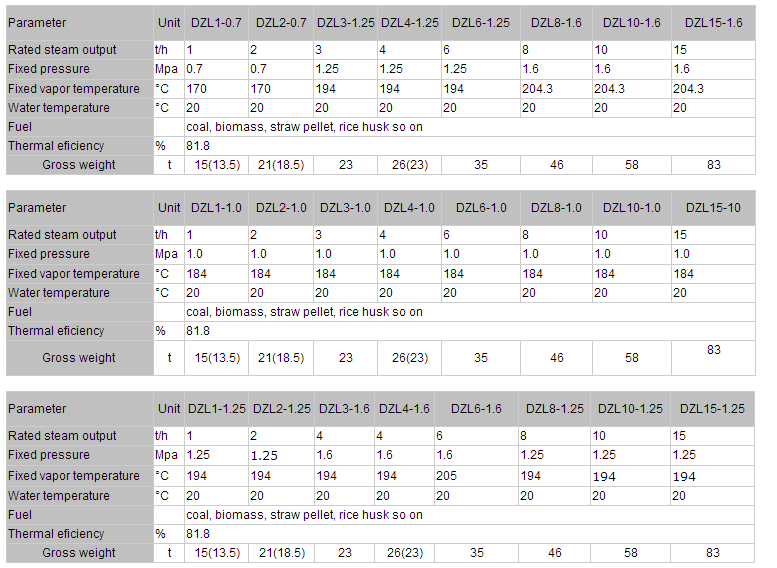

Best Price DZL Type 1-20T Steam Capacity 7 Bar 10Bar 12.5Bar 15BarCoal Biomass Steam Boiler With CE Certificated

DZL Type Coal /biomass Boiler Parameter

DZL Type Coal/biomass Steam Boiler Feature

- Coal/biomass boiler is durable and Long life time (more than 10years).

- Enough steam output, less heat dissipation, high thermal efficiency.lowest fuel consumption, lower power consumption.

- with high efficiency dust collector, more Eco-friendly.

- Full automatic control, Protection devices for overheating, overpressure, lacking water, leak detection, flameout

- The featured structure of the boiler: Threaded pipe, Airfoil flue , Convex tube plate , The backwater towards hightemperature tube plate, Simple loop circuit, Dust separated chamber, big furnace, compact structure so on.

1,Horizontal ,3 pass and large furnace

Ensure the sufficient combustion.

The large diameter boiler increase the heating surface to ensure the high thermal efficiency.

2,The spirally corrugated tube

Strength the heat transfer and improve the thermal efficiency .The smoke in the tube has the distribution effect,the dust not easy to deposit ,the tube can clean by itself.

3,High temperature resistance refractory brick

The furnace wall is poured by the heat resistance concrete and high temperature resistance refractory brick,decrease heat loss,increase the boiler thermal efficiency.

4,The economizer

Made of ND corrosion resistance steel,make full use of gas heat .reduce the exhaust temperature improve thermal efficiency.

Steam boilers' auxiliaries:

| Product name | Quantity(set/piece) |

| Boiler main Body | 1 |

| Induced Draft fan | 1 |

| Blower | 1 |

| Electric control Cabinet | 1 |

| Valve & Gauge | 1 batch for the whold boiler |

| Grate speed governor | 1 |

| Feed Water pump | 2 |

| Steam header | 1 |

| Chimney | 1 |

| Economizer | 1 |

| Fuel feeder | 1 |

| Slag remover | 1 |

| Dust Collector | 1 |

| Water softner | 1 |

| free spare parts | Several |

Note:We offer our steam boiler with all boiler auxiliaries.

We supply coal wood rice husk biomass fired steam boile/hot water boiler..

Capacity:1t,2t,3t,4t,6t,10t,15t,20t.

Pressure:0.7Mpa,1.0Mpa,1.25Mpa,1.6Mpa

To make sure our customers can get the boiler asap,we have lots of unfinished and finished steam boiler/hot water boiler in our storehouse.

And we also send our engineers to help our customers to install the boiler and train the boiler workers,and test the boiler to make sure the boiler can work safely and high efficiency

- long history: Founded in 1976, have about 40 years experience.

- Grade A manufacturer: Goverment approved Grade A boiler manufacturer, we can undertake all boiler project with pressure both under 2.5mpa and above 2.5mpa.

- Advanced equipement: design, techonics, welding, inspection, non-destructive testing, heat treatment, materials physics and chemistry inspection, device management each process will be stric supervised.

- SGS test report (extension test, bending test and material test of steel plate, tube and welding rod)

- Strength calculation report

- X-ray inspection (welding seam)

- NDT(non-destructive inspection) of steel plate, tube and welding rod

- Hydraulic testThird-party inspection.

1.One-year warranty and full-life service for our boilers.

2.X-ray test before delivery to guarantee the boiler's quality.

3.NDT test before delivery to assure the boiler's quality.

4.Free online installation guidance service.

China

China