Meat Dehydrator/Heat Pump Dryer/Fish/Fruit Drying Machine

Superior high quality industrial hot air dryer- Single drying chamber

Superior high quality industrial hot air dryer - Single drying chamber(two doors)

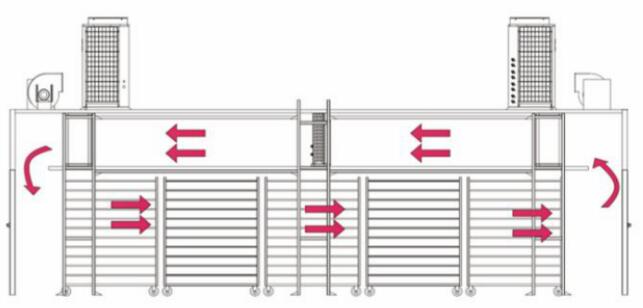

Superior high quality industrial hot air dryer- Milti drying chamber

application of Superior high quality industrial hot air dryer

Technical parameter of Superior high quality industrial hot air dryer

Model | ZL-KNC-12P-12A | ZL-KNC-18P-12A | ZL-KNC-18P-15A | ZL-KNC-24P-15A | ZL-KNC-72P-36A |

Voltage/frequency | 380V/50Hz | 380V/50Hz | 380V/50Hz | 380V/50Hz | 380V/50Hz |

Rated power of heat pump (Kw) | 11 | 16.5 | 16.5 | 22 | 66 |

Rated current(A) | 22 | 33 | 33 | 44 | 132 |

Heating capacity(Kw) | 38.5 | 57 | 57 | 77 | 231 |

Rated power of deputy heater(Kw) | 30 | 30 | 30 | 40 | 50 |

Rated current of deputy heater(A) | 60 | 60 | 60 | 80 | 100 |

heating capacity(Kw) | 30 | 30 | 30 | 40 | 50 |

Dehumidification capacity(L/H) | 30 | 45 | 45 | 60 | 180 |

Max. temperature of drying room(℃) | 75 | 75 | 75 | 75 | 75 |

Ambient temperature range(℃) | 0~43 | 0~43 | 0~43 | 0~43 | 0~43 |

Electric shock Rating (class) | 1 | 1 | 1 | 1 | 1 |

Max.pressure at expulsion(MPa) | ≤2.8 | ≤2.8 | ≤2.8 | ≤2.8 | ≤2.8 |

Noise[dB(A)] | ≤75 | ≤75 | ≤75 | ≤75 | ≤75 |

Air volume of fan (m3/h) | 36000 (in heat pump) | 36000 (in heat pump) | 72000 (in drying room) | 72000 (in drying room) | 160000 (in drying room) |

Weight(kg) | 1000 | 1400 | 1400 | 1800 | 5000 |

Drying chamber material |

75 mm thickness high density PU insulation material, both sides are 1.2 mm thickness mild steel plate with painting |

75 mm thickness high density PU insulation material, both sides are 1.2 mm thickness mild steel plate with painting |

75 mm thickness high density PU insulation material, both sides are 1.2 mm thickness mild steel plate with painting |

75 mm thickness high density PU insulation material, both sides are 1.2 mm thickness mild steel plate with painting |

75 mm thickness high density PU insulation material, both sides are 1.2 mm thickness mild steel plate with painting |

Overall dimension(mm) | 7000×2830×2795/4295 | 7000×2830×2795/4295 | 9000×2830×2795/4295 | 9000×2830×2795/4295 | 22000×2830×4500 |

Air direction model |

One direction, horizontal air flow |

One direction, horizontal air flow |

two direction alternate, horizontal air flow |

two direction alternate, horizontal air flow |

two direction alternate, horizontal air flow |

Trolley number | 12 trolley | 12 trolley | 15 trolley | 15 trolley | 36 trolley |

Loading area (SQM) | 180 | 180 | 225 | 225 | 540 |

(The above parameters are based on the ambient dry ball temperature 25 ℃, wet ball temperature 20 ℃, dehumidification amount based on the relative humidity 60%, due to different material structure caused drying time changes, the company has the right to update the parameters separately)

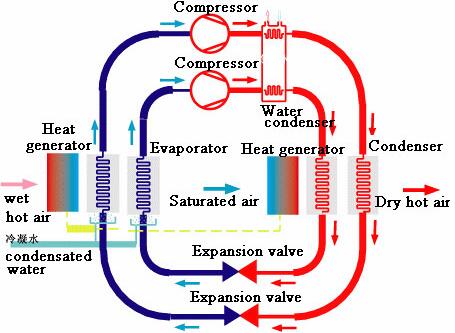

working principle of machine

Definition: Heat pump drying using the inverse Carnot principle, absorbing air heat and transport the heat to the drying room with hot air form, so that wet material in the drying room to the dried by the hot air.

Consist of:heat pump unit consist of compressor, condenser (within the machine), throttle, evaporator (external) and other devices together with the working fluid constitutes a heat transfer of the circulatory system.

Principle: heating, the first turn valve to the heat pump working position, so the compressor discharged from the high-pressure refrigerant vapor, after the valve into the indoor condenser, the refrigerant vapor condensed when the latent heat released, the drying room Indoor air heating, to achieve the purpose of heating materials. Condensed liquid refrigerant, from the reverse flow through the throttling device into the evaporator, absorb the external heat and evaporation, after evaporation of the steam through the valve after the suction by the compressor to complete the heating cycle.

Features of Hot air dryer

|

PACKAGE:

Standard export carton packing, fit for multiple handing and long distance marine shipping.

DELIVERY TIME:

3-20 days after confirming order,detail delivery date should be decided according to production season and order quantity.

We usually quote within 24 hours after we get your inquiry.If you are very urgent to get the price, please call us or tell us in your email so that we will regard your inquiry priority.

2) How do you make your price?

We make the price according to our comprehensive costing. And our price will lower than the trade company because we are manufacture.You will get competitive price and better quality.

3) Can you guarantee your quality?

Of course. We are the manufacture factory. More important, we put a high value on our reputation. Best quality is our principle all the time. You can be assured on our production completely.

4) How long does the whole procedure being worked out?

After you place a order,the production handling time is about 30-45 days. We need 7 days to prepare all the stuff then 30 days for manufacturing.

5) What about the transportation and delivery date?

Normally we use shipment to transprot the goods.It is about 25-40 days.It also denpends on which coutry and port you are. If there are some emergencies we can send the goods via air express, as long as you afford the traffic expense.

China

China