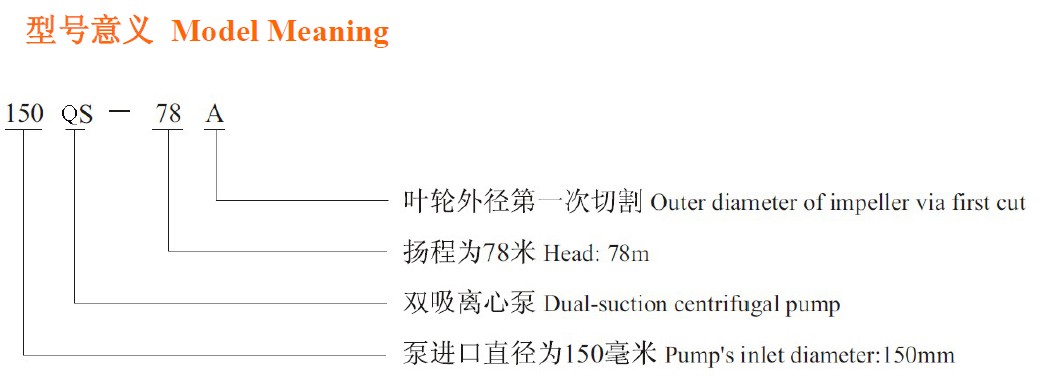

GENERAL

Model QS pump is a single-stage double-suction horizontal split centrifugal pump and used to transport pure water and the liquid of both physical and chemical nature similar to those of water, the maximum temperature of which must not be over 125 , suitable for water supply and drainage in factories, mines, cities and electric stations, waterlogged land drainage and irrigation of farming land and carious hydraulic projects. This series pump comply with the standards of GB/T3 216 and GB/T5657.

QS SPLIT CASING PUMP PARAMETERS

Model | Flow rate (m3/hr) | Head (m) | Speed (rpm) | Power (kw) | Eff (%) |

QS150 | 110~220 | 35~84 | 2900 | 30~55 | 67~80 |

QS200 | 160~351 | 31~100 | 2900 | 37~110 | 67~85 |

QS250 | 324~612 | 8.6~71 | 1450 | 22~132 | 72~86 |

QS300 | 504~972 | 8~98 | 1450 | 30~300 | 70~84 |

QS350 | 745~1663 | 10~140 | 1450 | 55~680 | 70~88 |

QS400 | 900~1620 | 32~98 | 980~1480 | 155~500 | 71.5~84 |

QS500 | 1150~2450 | 10.6~108 | 740~970 | 110~800 | 70~89 |

QS600 | 2304~4000 | 13~80 | 730~970 | 185~900 | 70~91 |

QS700 | 2111~4896 | 39.5~99.5 | 740~980 | 560~1250 | 72~92 |

QS800 | 3960~7200 | 23.5~84 | 600~740 | 450~1600 | 77~92 |

QS1000 | 6000~9900 | 32~52 | 600~990 | 1250 | 79~87 |

QS1200 | 5832~14400 | 6~95.7 | 500~745 | 710~3450 | 80~90 |

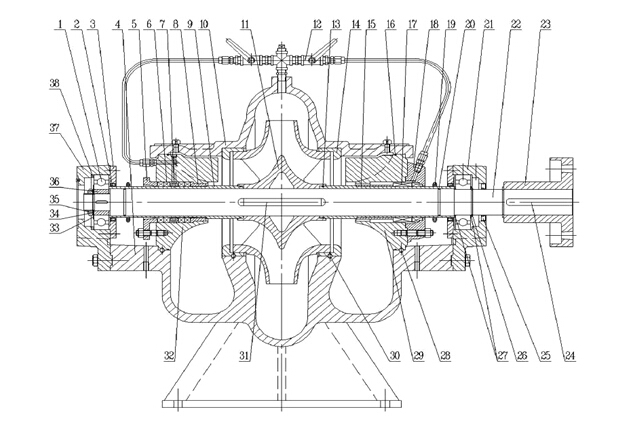

QS SPLIT CASING PUMP STRUCTURE

Both inlet and outlet of this pump are placed under the axial line, horizontally and vertical to the axial line, the pump casing is opened in the middle, so it is unneccessary to remove the water inlet and outlet pipelines and motor(or other prime movers). The pump moves CW viewing from the clutch to it. The pump moving CCW can also be made.

The main parts of the pump are: pump casing, pump cover , impeller , shaft, dual-suction seal ring, muff, bearing etc.

The impeller is static-balance calibrated, fixed with the muff and the muff nuts in both sides and its axial position can be adjusted via the nuts and axial force gets balanced by means of the symmetrical arrangement of its blades.

The pump shaft is supported by two single-column centripetal ball bearings, which are mounted inside of the bearing body on both ends of the pump and lubricated with grease. The dual-suction seal ring is used to reduce the leak at the impeller

The flexible couplings connect the pump with the motor directly. For pumps driven by belt, there must be an intermediate bracket fitted for supporting the belt pulley.

1.Bearing | 2.Framework oil seal | 3.Bearing gland | 4.Pump casing | 5.Packing gland | 6.Packings |

7.Packing ring | 8.Packing sleeve | 9.Shaft sleeve | 10.Pump cover | 11.Impeller | 12.Washing pipe |

13.O ring | 14.Seal ring for casing | 15.Mechanical seal liner | 16.O ring | 17.Mechanical seal | 18.Mechanical seal gland |

19.Water retaining ring | 20.O ring | 21.Bearing housing at driven end | 22.Shaft | 23.Couplings | 24.C type key |

25.Framework oil seal | 26.Shaft ring | 27.Bearing junk ring | 28.Cylindrical pin | 29.Mechanical seal | 30.Cylindrical pin |

31.B type key | 32.Packing seal | 33.Seal | 34.Round nut lock washer | 35.Round nut | 36.Bearing inner liner |

37.Pump end bearing housing | 38.Bearing spacer |

APPLICATION OF QS SPLIT CASING PUMP

FACTORY OF AN PUMP MACHINERY

We have many high qualified, excellent professional, and broad experience technician and managing outstanding person. Our company absorbed new science and technology fruit from home and abroad, having empoldered series of high level pump products. Our team has strong capacity of pumps technology development, from selection&design, solution options, to manufacturing&setting, and energy saving, environment protecting, and so on. We can help the clients cut down about 50% cost at the same time meeting the end users requirement

PACKAGE REFERENCE

SHIPPING

FAQ

1. Q: Are you a trading company or manufacture?

A: An Pump Machinery Co., Ltd is a real large professional manufacturer more than 32 years, in China, produce with our own factory.

2. Q: what's your factory workshops ?

A: My factory produce include casting, mechanical process, lathe process, heat treatment, assembly, and test etc.

Warmly welcome to visit & test my factory any time.

3. Q: How about your QS centrifugal horizontal split casing double suction pump price?

A: We are sure our price is factory price, and insist hig quality for our long term cooperation.

4. Q: What is your QS centrifugal horizontal split casing pump material ?

A: For the QS pump, we could produce cast iron, cast steel, stainless steel, bronze, and material high CrMoNi alloy.

And we could also produce as your requirements.

5.Q: What kind of liquid can your QS pump transfer?

A: Liquid range: water, chemical liquid, hot water, sewage etc.

6. Q:How does your factory do regarding quality control?

A:"Quality is priority. we always attach great importance to quality controlling from the very beginning to the very end.

Our factory has 15~30 QC.

7. Q: Is it easy for customers to change the parts by myselves ?

A: yes, the structure is simple ,customers can change spare parts very easliy. We will also supply you maintenance tools for free.

8. Q: How to do if the pump or parts have operatation problem within your warranty?

A: Tell me details timely, and show me pictures, we will send you solution at once without any hesistation.

9. Q: Can you install the motor or diesel engine with the pump for us ?

A: yes, we can, it's no problem, we are experienced in this .

10: Q: .we don't know which pump model we need ,can you help us ?

A: yes, please tell me your detail requirements, include liquid, flow rate, head etc,

my engineers team wiill calculate & select most suitable pump model for you, offer pump solution for you.

11. Q:How long can you reply us if we send an inquiry ?

A: Generall within 2 hours, we will send you official quotation sheet, with price, technology data, performance curve, dimension etc.

COMPANY INFORMATION OF AN PUMP MACHINERY

Shijiazhuang An Pump Machinery Co.,Ltd is a manufacturer and trading enterprise, which is mainly engaged in pump designing, manufacturing, selling and service. We develop the international trading business of mining equipment, slurry pumps, and water pumps according the wide customer resource, comprehensive technology and reasonable staffing.

Now, our products had exported to more than 40 countrys. And widely accepted for the high quality products and attentive service. With the deepening of economic globalization and the rapid development of information technology, the team of An Pump is glad to cooperate with you to create a brilliant future.

An Pump Machinery Co.,Ltd is end manufacturer in China, mainly produce centrifugal pump.

Our engineers steam could select most suitable pump model according your detail requirement.

Any question&request, please contact me, i will try my best to help you.

24-HOUR ONLINE SERVE.

CONTACT

China

China