New design micro 500L beer brewery equipment with conical fermenter

Visual saccharification

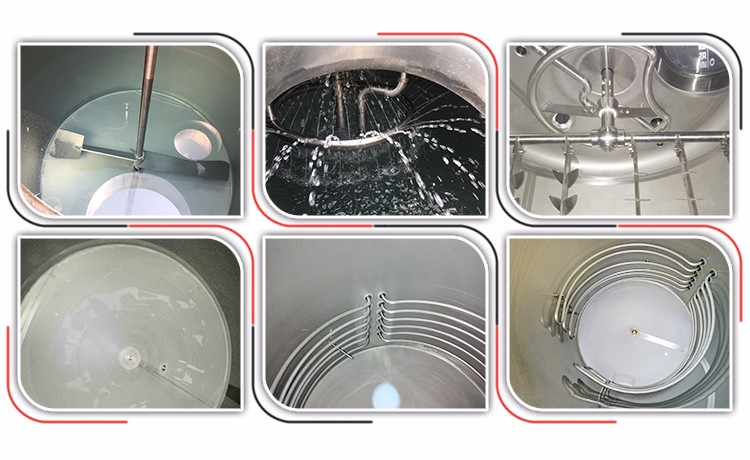

Saccharification equipment with pressure glass manhole design, with spotlights auxiliary functions.

With this design, you can reduce the degree of oxidation of beer, beer oxidation lighter taste. Help to improve the quality of mature beer.

Saccharification design We use pressure glass manhole, saccharification process without opening the manhole conditions, turn on the spotlight, we can better observe the whole process of malt saccharification through the glass manhole. In the wort boiling process, we can intuitively see the wort boiling strength, wort is less susceptible to oxidation, get better quality wort.

Hole-shaped non-slip design

Beer brewing process, the platform will have residual water. Wear rubber shoes, feet slippery. Our company through practice, the use of a new hole-shaped non-slip design, greatly enhanced the anti-skid function, platform operation more secure. No need to worry about platform skidding with the new non-skid design.

spent grain sparging design

The lauter tank of Saccharification equipment use spent grain sparging design, the traditional process when the filter is completed, add a certain amount of hot water to wash the bad, the middle need to open the plow, stationary 20 minutes, reflux and other modes of operation. New design form without Opening the plow knife, rest for 20 minutes, back flow. Compared with the traditional design methods are as follows:

The entire filtration process saves about one third of the time, at least 40 minutes or more, greatly saving operating time and labor costs.

At the same time, our utilization of malt higher, residual sugar lower, because we use the the liquid wash bad. Reduce the cost of beer materials.

Filtration time is reduced, the overall oxidation time is shortened, and we also get wort of higher quality, reducing the oxidation time of the wort. Improve the quality of finished beer.

a.) Free consultation service before, during, and after sales;

b.) Project planning and design services,CAD,3D.The CAD design need 2-3 workdays.The 3D design need 7 days.

c.) Management of equipments' long distance shipping from seller's factory to named port or station by buyer;

d.) Training of equipment maintenance and operating personally;

e.) New production techniques;

f.) Provide 36 months complete warrantee for tanks body and life-time maintenance service; All of the accessories and auxuliaries facilities are guaranteed for one year; The seller is responsible for the nature damage of the machinery in the warranty period except for man-made damage. All spare parts and wearing parts are attached with the machinery for free.

We passed the CE PED LVD certification. Besides Our company adheres to the principle of high quality and low price. please tell me your specific requirements, So I will give you an accurate quote, detailed configuration list, technical drawings and CAD layout according to your site. Choose me, Let you save time and energy.

China

China