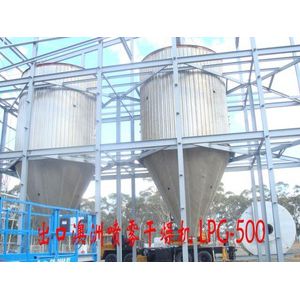

High quality Emulsion Centrifugal Spray Dryer

Simple Instruction: |

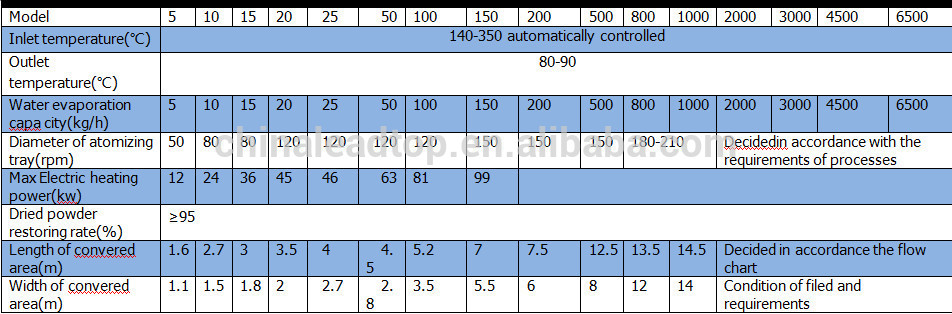

The spray drying is the technology most widely used in the liquid technology shaping and in the drying industry. The drying technology is the most suitable for producing solid powder or particle products from liquid materials, such as: solvent, emulsion, suspension and pumpable paste states, fro this reason, when the particle size and distribution of the final products, residual water contents. Mass density and the particle shape must meet the precise standard, spray drying is one of the most desired technology. |

Working Principle: |

Hot air is distributed downwards with spiral method into the drying tower after filtering and heating. Meanwhile, solution is nebulized millions of single granule and form fog drop. Then the fog drop contact with the hot air and most of the water flash immediately to form the dry product. These powder and granule fall into the air exhaust pipe at the bottom of the drying tower, collected in the material tank. |

Feature: |

|

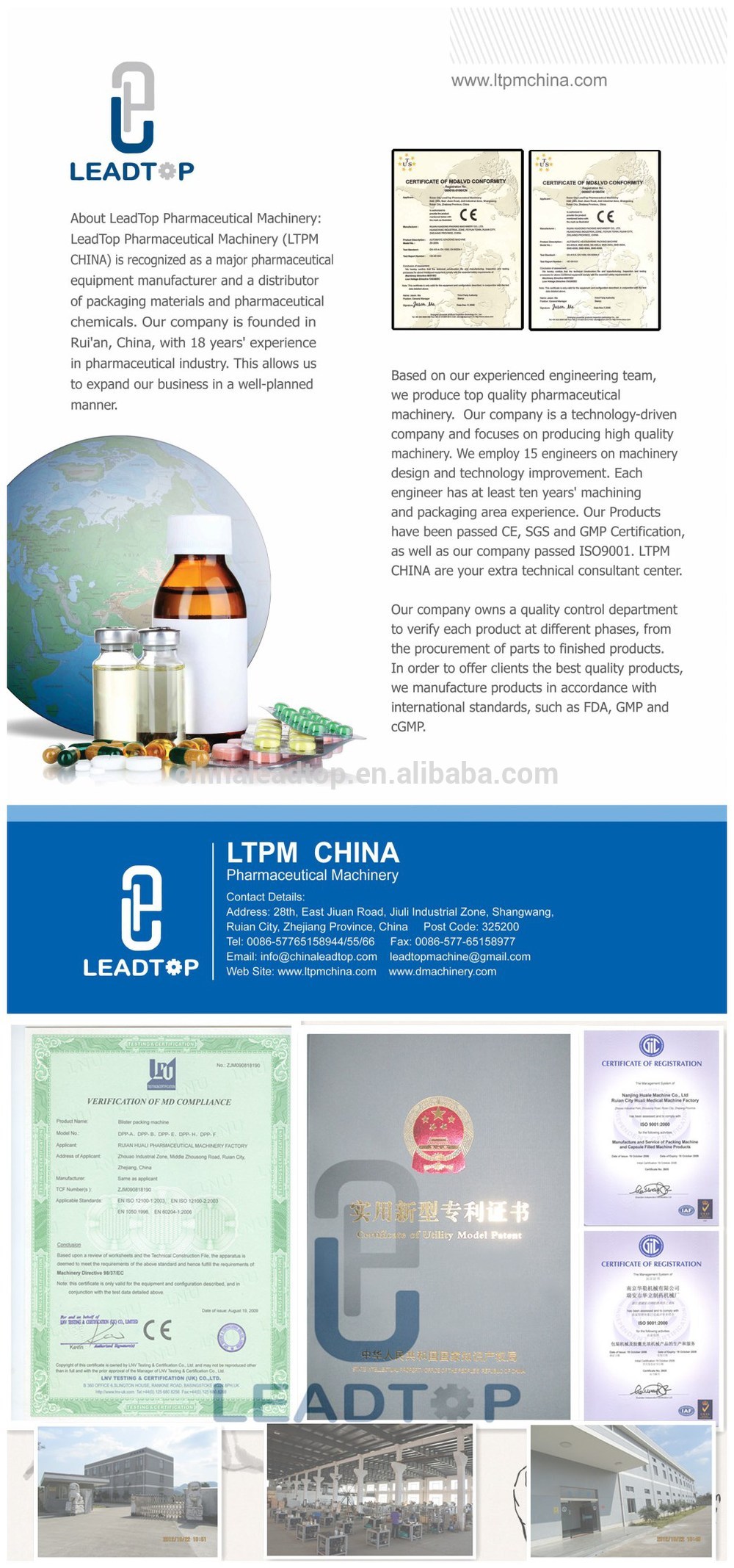

1. 24*7days hotline service.

2. Technology Support: we offer engineer at site training and intsllation service all over the world.

3. Documentation: DQ, IQ, OQ, PQ, FAT, SAT, Manual, etc for GMP validation purpose.

4. One year spare parts Free Guarantee

5. Production Solution Suggestion

LTPM CHINA Your Best Pharmaceutical Production Solution ! Welcome to contact us for more information.

China

China