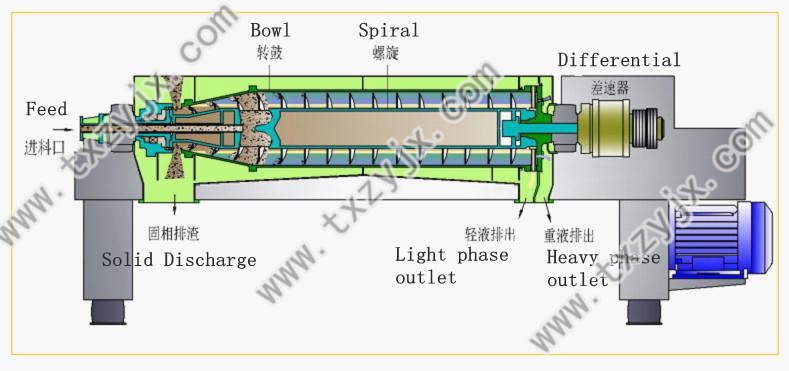

1.Separation Principle of 3 phase Horizontal Decanter Centrifuge

The 3 phase Horizontal Decanter Centrifuge with the standard horiztontal spiral centrifuge workds similar to solid density is different, relying on centrifugal force field to achieve settlement stratification, the liquter liquid closer to the rotation axis line, the closer the heavier liquid drum wall, the heaviest solid settling in the drum wall, the severity of the respective channels discharging the liquid from the door design, the solid phase is discharged of screw conveyor.

Part of the machine can be equpped with liquid-liquid-slid separator the heart pumps, one of which may be second phase of the cardiac pump discharge, another liquid discharged throught the liquid collection chamber cover. Using centripetal pump liquid discharge liquid gasification can reduce and prevent the liquid separated from each other within the casing leak remix.

2.Description Of Liquid Liquid Solid Decanter Centrifuge

Process advantages of 3 phase Horizontal Decanter Centrifuge

Process flexibility

Constant separation results, even at fluctuations in the volumetric flow, the process conditions, or the product characteristics

Process conditions

1)gas-tight, vapor-tight, or pressurized operation

2)low vibration levels

3)absolute pressures from 0 to 8 bar

4)-90° C to +200° C

5)CIP cleaning

6)flameproof or explosion-proof standards making the decanter ideal for applications with solvents and hazardous materials

Cemical resistance

Materials such as titanium, pure nickel, or Hastelloy provide the security essential in demanding process applications.

Low space requirement

1)compact design at high specific throughput

2)self-contained system, therefore no extra space required for peripheral equipment

Low operating costs

Operating consumables (e.g. filter cloths) are not required. No costly downtime for changing consumables.

Simple installation

1)integration of all necessary functions in one package (e.g. no need for peripheral equipment)

2)active support system (no foundations)

Operation

Clarification

Clarification is the separation of solids from a liquid of lower density over a particle size range from 1 to 10,000 microns.

By increasing the centrifugal force, it is possible to also separate very small particles in the submicron range, even with very small differential density.

Classifying

By controlled reduction of the residence time, classification according to particle size, down to the submicron range, can be achieved with sharp separation cuts.

Liquid/liquid separation

Liquid phases of differing densities can also be separated.

Thickening

Fine solids separated from the liquid can be thickened in a hindered settling mode, utilizing the volume of the cylindrical section of the decanter to maximize compression.

Compression

Compactive dewatering provides a substantially higher degree of dewatering with compressible solids.

Washing

Efficient and cost-effective counter-current washing is made possible by separate removal of the wash liquor over several sections of the screen.

Dewatering

The solids dewater by a combination of drainage and compression. The degree of drainage/compression depends on the nature of the solids, the setting of the centrifuge, and the required degree of dewatering. The transport and discharge of pasty, sludge-like or shear-sensitive solids are facilitated by the appropriate combination of conveyor geometry, cone geometry, and control of the differential speed.

Mixing and re-suspension

Special solids discharge geometry (gutter) allows the dewatered solids to be mixed with liquid directly at the discharge, thus eliminating the need for an additional mixing vessel.

Major applications

1)Organic chemicals

2)Inorganic chemicals

3)Ores and minerals

4)Water and wastewater

5)Food and pharmaceuticals

3. other Applications Of Product

The decanter centrifuge can be used for most types of liquid/solid separation. It can be used for the classification of solids in liquid suspension or for the clarification of liquids. It can also be used in the recovery of a valuable solid from its suspension in the liquid and it can wash the recovered solid from its mother liquor.

The most common application is separation of solid substances from high concentrated suspensions. Used in this way for the treatment of sewage sludge it enables the dewatering with the production of more or less consistent sediment depending on the nature of the sludge to be treated, and the accelerated thickening of low concentration sludge.

4.More Product for Choose

5. Packing of Product

6. Sample Rooms of Product

1. Introduction of Company

Liaoyang Tianxing Pharmaceutical Machinery Factory has been engaged in the production of centrifuge&separation machinery from 2004. The main products are tubular centrifuge, disc stack centrifuge, filtering centrifuge and decanter centrifuge etc which are widely used in food&beverage, chemical, pharmaceutical, biology, environment protecting etc industries. We have a excellent team which can provide you with efficient and reliable technical service and support.

Adhering to the spirit of "professional, high-quality, efficient, honest ", we has developed into a professional and experienced factory.

Realize your ideas, we assure your excellence with low cost!

2. Workshop of Our Company

3. Our Customers

4. Best Service for You

1) 7day*24hours Hot-line & Email Service

2) Your inquiry related to our products or prices will be replied in 24hours.

3) Well-trained and experienced staffs to answer all your questions in fluent English.

4) Abundant spare parts in stock are available to provide.

5) Our technicians could be dispatched for overseas service.

6) Your workers could get trained in our factory.

5.Welcome to Contact Us

6.FAQ

1. How can we visit your factory?

If you come from abroad, air to Shenyang Taoxian airport which is very near to our city about 40 minutes driving. If you come from domestic city, train directly to Liaoyang, we will pick you up both in the airport and railway station.

2. Can we do test with your centrifuge?

No problem and it is free. You can come to our factory to do the test or we do the test for you and you can see the whole process by internet.

3. Can we visit your end user or contact them?

Yes, users are in domestic and abroad, we can provide you the name list, you can go there or contact for more info.

4. How do you protect the quality?

Our factory is a state owned enterprise with more than 10 years experience, strict operation policy is performed, advanced processing machines guarantee the precision of all components, workers with operation license, parts get multiprocessing, transmission & electrical parts. Series of test and inspection are done in the whole producing stage.

5. Will you dispatch technicians for installation and commissioning?

Yes, we can, we do lots of service, please refer to our after sales part.

6. What are your advantages compared with your competitors?

Quality and experience. We are the top centrifuge supplier in China, our designs and structures are similar to world leader Alfa Laval, Westfalia, Flottweg, etc.

7. Is your price competitive?

Our price is not the lowest in China as for high quality, but we promise, for the same quality and collocation, our price is the most favourite, for the same price, our quality is absolutely superior to other brands.

8. Do you have ODM service?

Yes, we do, as long as you provide us your brand.

9. How can we easily find out the fittest centrifuges?

We have experienced engineer team to help you make the model selection, as long as you provide us the detailed requirement on your process and material will be separated.

10. What payment mode you accept?

TT and LC at sight.

11. How long is your delivery time?

Generally it is 5-10 days if the goods are in stock. or it is 10-40 days if the goods are not in stock, it is according to quantity.

China

China