Factory Paint lab making equipments horizental pin type bead mill with CE certificate

ESW-1.0 1L Pin type Harden Alloy Horizental Bead Mill for paint, coating, ink...

ESW-1.0 1L Pin type Harden Alloy horizental bead mill for pait, coating, ink...

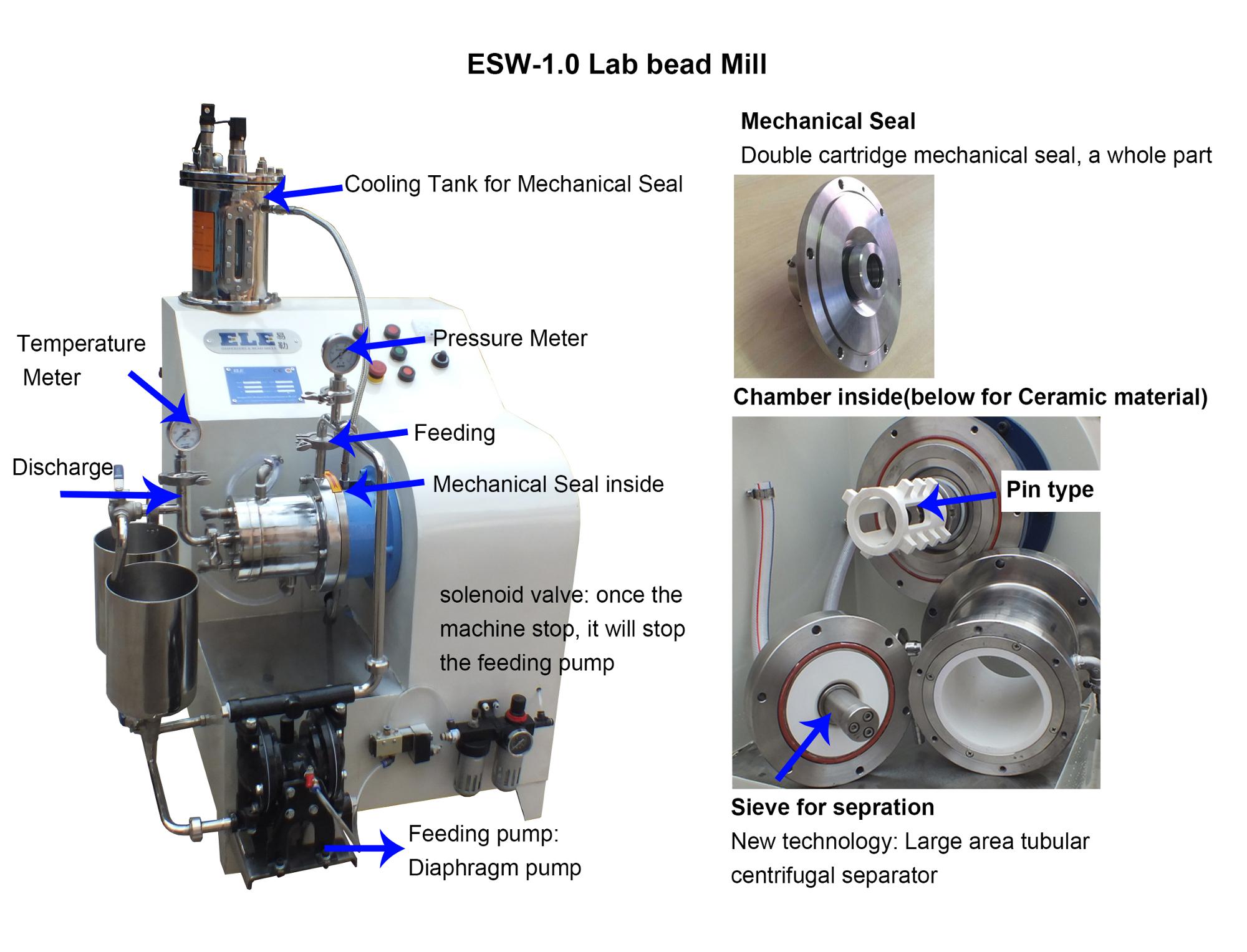

1. Introduction for horizontal sand mill/one of main equipment for paint prodution

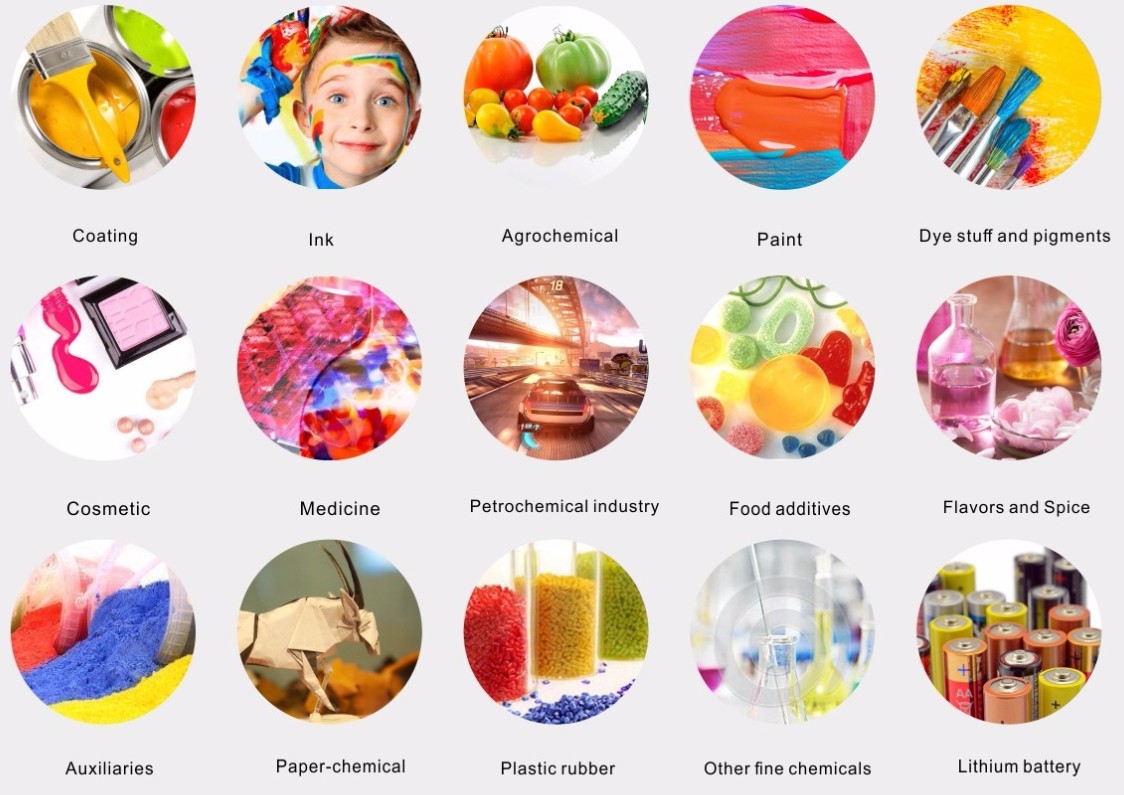

ESW bead mill series are ELE’s patents, they adopt the most advandced L/D ratio, double mechanical seal, scientific cooling systems and advanced material discharge method, etc. ELE is always a leader in grinding and dispersing technology over years, and ELE mills are widely used in dye and pigment, paint and coating, electronics, ink, pesticide SC/EC, Chemical, food and cosmetics industries etc.

Application:

2. Features

1) Suitable for material with high solid powder and liquid, high refining requirements .

2) Compact body design, carbon steel frame, stainless steel machine parts, excellent painting effect.

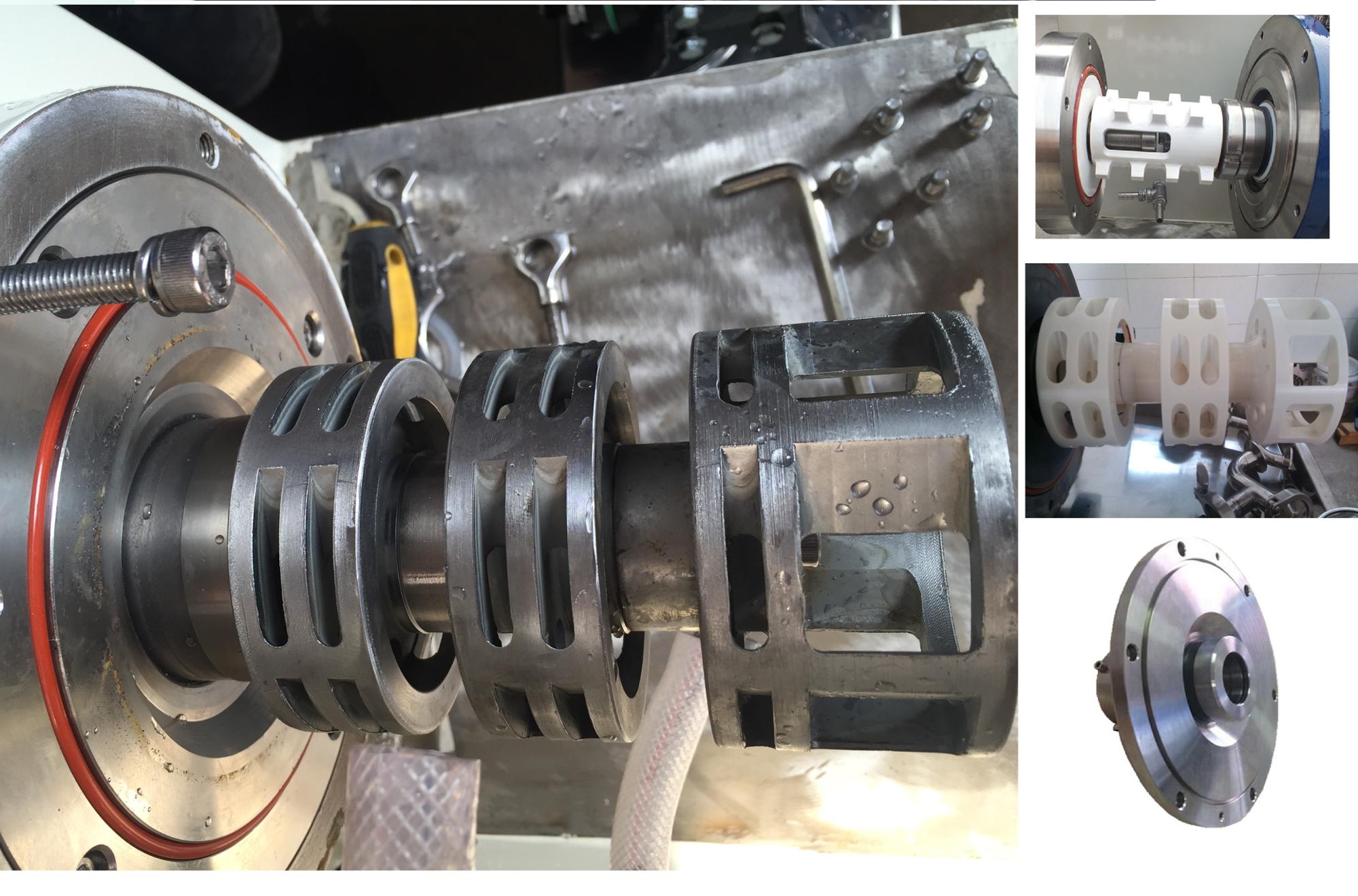

3) Advandecd imported double mechanical seal, which ensures the long life of shaft seal and good sealing effect .

4) The grinding barrel and shaft adopts forced water circulation and the mechanical seal adopts oil cooling system, which ensure the best cooling effect.

5) ESW series grinding mills adopt unique large area tubular reseau separator, precise separation & smooth discharge solve the problems of slow discharging speed and blocking of grinding medium. It can use ultrafine grinding medium, and the smallest discharging sieve could be 0.05.

6) The whole grinding barrel and shaft and beads adopt high-strength alloy steel, zirconia, silicon carbide, etc, which ensures the long life and reduce metallic pollution.

7) ELE has button control and PLC control for your choose, We also has explosion-proof type for special working environment.

3. Technical specification

Model | Cavity volumn(L) | Power (KW) | Rotation speed (rmp) | Capacity (L/H) |

ESW-1.0 | 1 | 4 | 0-3000 | 2-30 |

Note: we can do special design according to customers’need. |

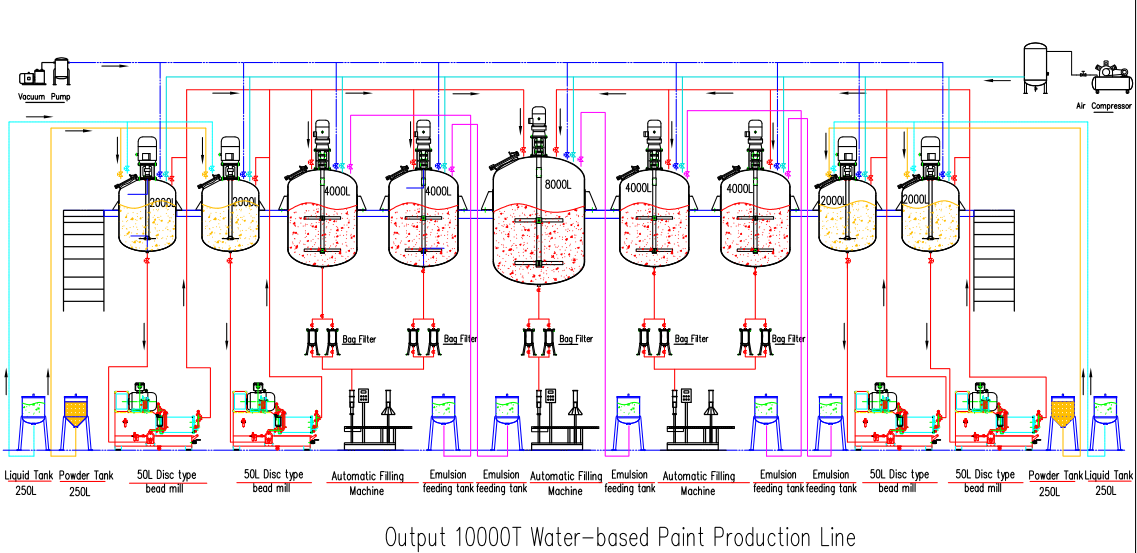

4. Painting Production Line Drawing

5. Our Service

6. Engineer Commissioning overseas

7. Our Factory

7. Free Laboratory Service

1. Customer Material Sample Received - 2. Grinding material - 3. Particle Size Test- 4. Send Test Report - 5. Send Finished Material

8. Customer Visit Us & Visit Customer

9. Our Exhibitions

10. Our Certificate

11. Package and Shipping

12. Product Range

I. Oil Paint Brief

oil paint is a substance firm coated on object surface,for purpose of protection,decoration and other special use chemical coatings mixture.

II. Paint Category

1.By position,it can divide into wall paint,wood paint,metallic paint.Wall paint includes outer wall paint, internal wall paint,top surface paint,mainly latex paint,wood paint includes nitro-lacquer paint,polyurethane paint etc;metallic paint is enamel paint.

2.By form,it can divide into water based paint,solvent paint,latex paint is mainly water based paint,while nitrate lacquer paint,polyurethane paint are solvent based paint.

3.By function,it can divide into water proof paint,fire proof paint,mildew resistant paint,anti-mosquito paint etc.

4.By usage,it can divide into volatile paint and non-violating paint.

5.By surface effect,it can divide into transparent paint,semi-transparent and opaque paint.

III. Main equipment concerned for oil based paint

1.paint disperser,can achieve pre-dispersing,mixing,high speed dispersing,coatings mixing,color mixing,and it is with good suitability for high viscous and thixotropic material,especially for mass production.Paint mixer can crash,disperse,homogenize,blend and through toothed disc up and down high speed rotating,it realizes function of high speed violent crashing,hit,shearing,dispersing to quickly blend,dissolve,disperse and refine.It is a high efficient equipment for solid-liquid mixing,dispersing,dissolving.

2.Horizontal sand mill,a high efficienct wet super fineness grinding machine in coatings,dyes,paint,ink,medicine,photographic film,pesticides,paper making and cosmetics etc non metallic mineral field.By structure,horizontal sand mill can divide into pin rod type,disc type and double cone type.

3.Paint mixer,one machine with leaf agitator on the shaft rotating inside round shell or slot,mixing several raw material to form mixture and suitable viscous product.It is widely used in coatings,ink,pigment,and binder etc chemical products.

4.For paint reacting vessel,agitator can be paddle,frame,anchor,etc.normally it is low speed mixing.It can heat,customize pressured.

5.Paint filling machine,is mainly for a small fractional product.By production automation,it can divide into semi-automatic and fully automatic filling machine production line. By material filled,it can divide into ex-proof filling machine and common type filling machine.

All kinds of ink production line design and manufacturing such as water-based ink,UV ink,screen printing ink,print ink,seiko ink and offset printing ink are within our business range.We also provide whole plant construction services.

China

China