Jiangsu Peony PS300 Hand Salt Centrifuge for Used Oil

Brief Introduction of Jiangsu Peony PS300 Hand Salt Centrifuge for Used Oil :

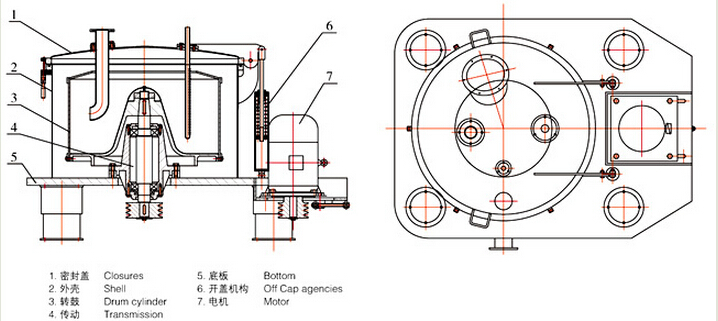

1. This type of centrifuges are top discharging, hermetic closure type filtrating equipment.

2. Operation and adjust by PLC and discharged manually from the top cover.

3. The bowl can be made of Stainless Steel 304.

4. Smooth running, easy control, hermetic closure operation, reduce cross contamination.

5. A visual glass is added on top of the cover, easy to watch details when it`s running.

6. The material of the body is normally covered with stainless steel sheet.

7. Use flat plate to counter weight and high viscosity damping vibration to absorb vibration. No foundation required.

8. Applicable of filtrating solid granules, high viscosity toxic and flammable materials, chemical, medical and mineral powders. Widely used in Chemical, Pharmacy, Medical, Food, Light industry etc. flat filtering centrifuge ps600 flat-plate upper discharging centrifuge industrial chemical manufacturers,

The PS flat-plate upper discharging centrifuge is based on tripod filtering centrifuge, without holes in the wall of the bowl.

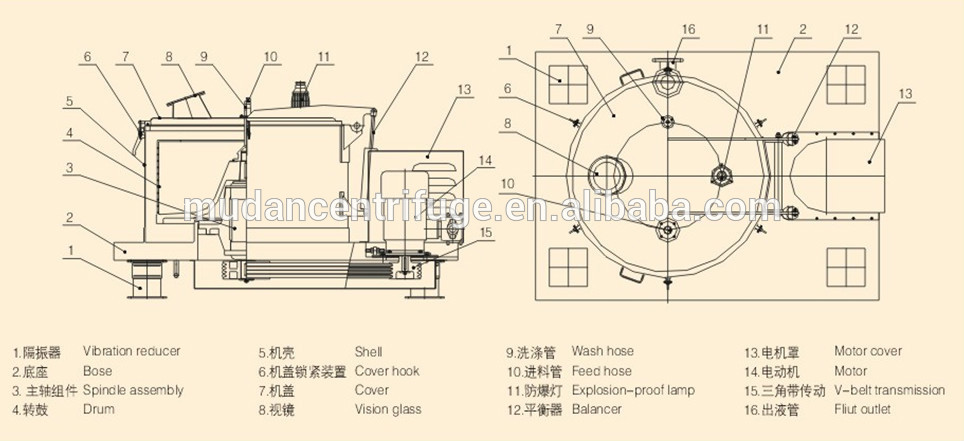

Reasonable structure design, geometric shapes simple and effective elimination of the health corners, structural parts smooth transition, the surface polished, external components, fasteners and materials are made of stainless steel contact parts, housing for the clamshell, can centrifuge housing and Drum sandwich in a thorough cleaning.

Base and the flat structure, reducing the machine center of gravity, small size, the overall base and the shell is welded form, bearing strength.

Configuration of liquid rubber damping shock absorber damping fluid or, more effectively eliminate the vibration can be realized without basic installation.

Shell can flip clamshell model with a large or small, flip, cover with feed tube can be equipment, washing pipe, observation port, light mouth and spray systems, other protective devices can be equipped with nitrogen to ensure the centrifuge separation chamber and outside air.

Direct type-specific motor, belt drive eliminates the potential dust, inverter start, start the smooth, dynamic braking, the whole good sealing performance, can be anti-explosion, can be applied to toxic and flammable, explosive situation. Nitrogen also can be equipped with protective devices to ensure the centrifuge chamber and the outside air isolation.

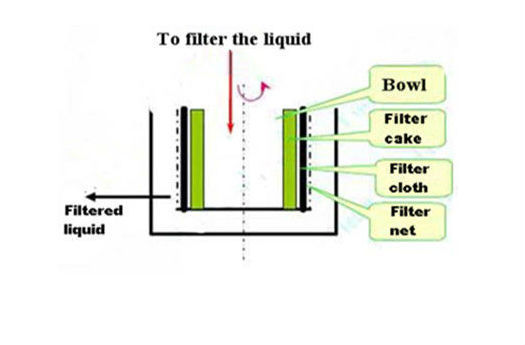

Working Principle of Jiangsu Peony PS300 Hand Salt Centrifuge for Used Oil :

To extract residual mother liquor from crystals by centrifugal force in normal temperature, the solid/crystals should contain no/less water content in fiber.

Product Drawings Jiangsu Peony PS300 Hand Salt Centrifuge for Used Oil :

Description:

1.brief introduction

This type of bag hoist discharge centrifuge are filter equipment with hermetic closure procedure task, intermittent operation and hanging bag off-site discharge.

2.working principle

The material is fed into the drum from the top; under the action of the centrifugal force filed, the liquid-phase passes through the filter medium and is discharged out of the machine, while the solid-phase material is retained inside the drum; after the machine is stopped, the liquid-block plate together with the filter bag is hoisted with the sling out of the machine and transferred to the designated discharge site.

3. application scope

It is applicable to the separation of suspension containing solid-phase granules with the diameter greater than 0.01mm.

And it is especially applicable to the filtering of toxic and flammable materials. It has found wide applications in such trades as chemical, pharmacy, food, light industry, etc.

For example: gypsum, thiamine, mirabilite, ferric sulfate, copper sulfate, nickel sulfate, potassium chloride, acetic acid, borax, soda, rubber additives, dye, plastic raw material, soap, grease, all kinds of resins, food salt, sodium glutamate, food additives, starch sugar-making, vitamins, antibiotics, herbicide, insecticide, the dehydration of such mineral fines as copper, zinc, aluminum, etc.

Delivery time

1.For ordinary standard type ,the delivery time will be 25-30days after received the deposit

2.If there’s any special inquirement ,the delivery time will suitable extanded

Model Ps centrifuge is a type of horizontal, spiral discharging filtrating equipment with continuous operation. With the drum and the helix rotating in the same direction at high speed difference, the material is continuously led, via the feeding pipe, into the inner cylinder of the spiral feeder and, after acceleration, enters the drum. Under the action of the centrifugal force field, the liquid phase passes through the filtrating medium and is discharging out of the machine, while the solid-phase material is retained inside the drum and forms the filter residue. Under the combined action of the conic surface component force of the centrifugal force and the spiral feeder, the filter residue continuously moves towards the big end of the drum and is discharged out of the machine through the discharging trough. This machine is capable of continuous feeding, separating, washing and discharging during the full-speed running. It has such features as compact structure, small space occupancy, continuous operation, smooth running, strong adaptation, large handing capacity, low moisture content in the filter cake, etc.

Applications:

It is applicable to the separating of suspension liquid containing the solid-phase material with the granule size greater than 0.1 mm and concentration being 25! 75% or the separating of short fibers. It has found wide applications in such industries as chemical, salt making, alkali making, environmental protection, etc.

Main Technical Parameters Jiangsu Peony PS300 Hand Salt Centrifuge for Used Oil

| Model | PS300 | PS450 | PS600 | PS800 | PS800A | PS1000 | PS1000A | PS1200 | PS1200A |

| Bowl Diameter (MM) | 300 | 450 | 600 | 800 | 800 | 1000 | 1000 | 1200 | 1200 |

| Bowl Volumn (L) | 5 | 20 | 40 | 100 | 100 | 150 | 150 | 250 | 250 |

| Loading Limit (KG) | 10 | 25 | 50 | 135 | 135 | 200 | 200 | 300 | 300 |

Rotate Speed (R/Min) | 2500 | 1900 | 1500 | 1200 | 1500 | 1000 | 1200 | 800 | 950 |

Separate Factor | 1050 | 910 | 756 | 645 | 1008 | 560 | 806 | 430 | 606 |

| Motor Power (KW) | 1.1 | 1.5 | 3 | 5.5 | 7.5 | 7.5 | 11 | 11 | 15 |

| Machine Weight (KG) | 180 | 250 | 800 | 1300 | 1500 | 2000 | 2300 | 2500 | 2900 |

Applications Of Product

The decanter centrifuge can be used for most types of liquid/solid separation. It can be used for the classification of solids in liquid suspension or for the clarification of liquids. It can also be used in the recovery of a valuable solid from its suspension in the liquid and it can wash the recovered solid from its mother liquor.

Packing of Jiangsu Peony PS300 Hand Salt Centrifuge for Used Oil :

1. The body of the machine covered with plastic film.

2. The machine install into standard wooden case.

3. Container delivery.

Shipping of Jiangsu Peony PS300 Hand Salt Centrifuge for Used Oil :

45 Days after down payment.

Land Transportation: By truck.

Sea Transportation: By ship.

Peony Service

Pre-sale services:

1> Provide the free consultation of the equipment

2> Provide the standard device and the flow chart

3> According to the clients’ special requirement, offer the

reasonable plan and free design help to select the equipment.

4> Welcome to visit our factory or the domestic clients’ factory.

Services during the sales:

1> Help client design the factory and offering professional advice,

free engineering drawing for the factory layout.

2> Inspect the machine before leaving the factory.

3> Oversea install and debug the equipment.

4> Train the first-line operator.

5> Provide the basic formula

After sale services:

1> 24 hours online service

2> Engineers available to service machinery overseas

3> Provide technical exchanging

Please feel free to contact us,we will reply within 24h!

We want to know more about your product:

1.raw material

2.solid content and solid particle size

3.moisture content after drying

4.capacity per hour

Our price:

We never say high price,we keep only 5% profit for factory in the price,that's why clients always praise our quotation in reply.

China

China