Boiler ion exchange blue water softener system

| Product name:Boiler ion exchange blue water softener system |

| • Model number: water softener filters capacity 2m3/h | |

| • Filter named: Industrial water softener filters | |

| • Resin: PurolitePresin | |

| • Resin tanks: Inner shell: PE, outer layer: FRP | |

| • Valve: Automatic Control Softening Valve with multiport Valve | |

| • outlet softed water hardness: ≤0.03mmol/L | |

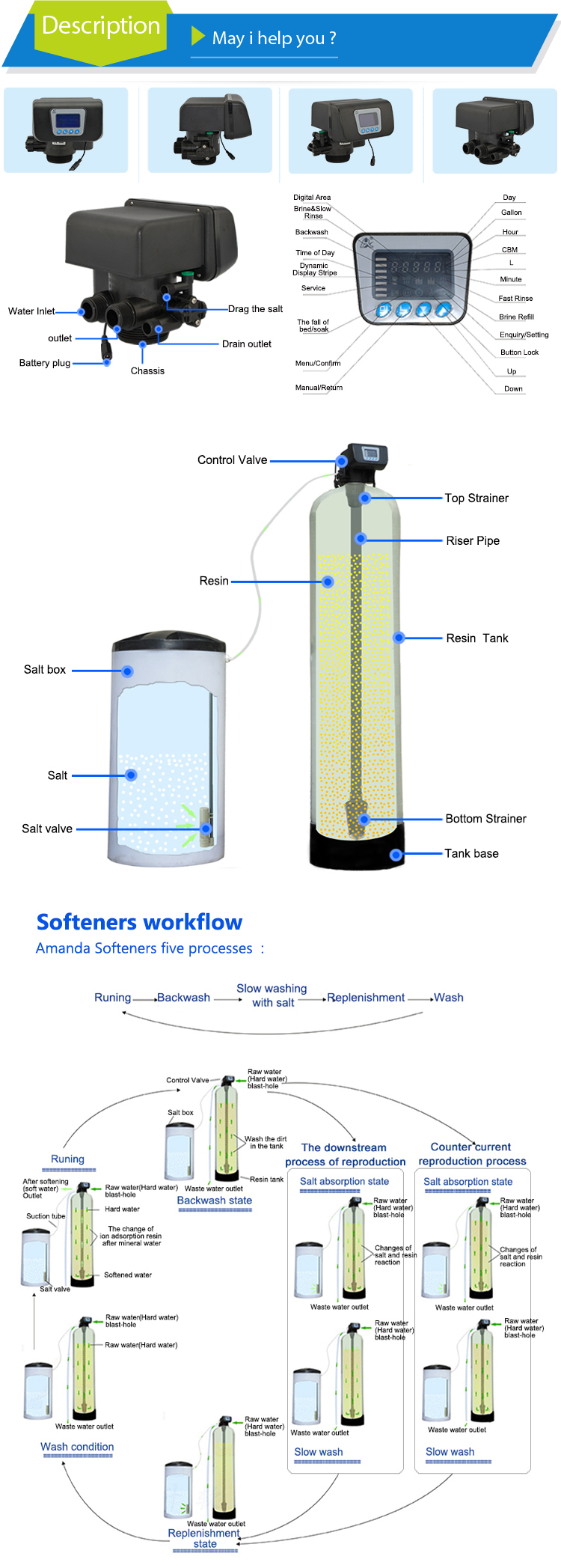

Amanda Automatic Water Softeners Characters

• Sealing parts is made of high hardness and high flatness ceramic grinding, low failure rate, long service life.

• Micro-omputerized controller with memory function, when power on again after outage, the original settings are intact.

• The time of regeneration cycle, backwash, suck salt, backwater, washing and other steps can be pre-set independently, the regeneration process save time and salt .

• Regeneration cycle is setted according to water usage, softed water is more assured, during regeneration, hard water no pass

Backwash: After working device , the upper block in the resin to bring a lot of raw water dirt, removal of thesecontaminants ,

the ion exchange resin to be fully exposed out of the effect of regeneration can be guaranteed.Backwash process is the wash

water from the bottom of the resin into , out from the top ,so you can put the top block down the dirt away. This process

usually takes about 5-15 minutes .

Regeneration:Coming into the resin tank brine process is the use of traditional equipment salt brine pump,automatic

equipment is built by private jet to saline inhalation ( as long as there is a certain pressure to the water )

Slow wash:After the salt water through the resin , with the raw water at the same flow rate of the resin in the saltslowly rinse

all thewashing process is called slow , as this washing process there are a large number offunctional groups on the calcium

and magnesium ions are sodium ion exchange , based on actual experience,takes about 30 minutes.

Wash:In order to thoroughly rinse the salt residue , to be used close to the actual work flow, withthe raw water to wash

the resin , the process of the final effluent standard soft water . Generally , the fast rinse process is 5-15 minutes.

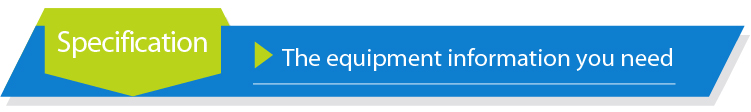

| Technical Specification | |

| Working Pressure: | 0.1~0.6 MPa |

| TDS: | ≤700mg/L |

| Production Capacity: | 1~35m3/h |

| Raw water temperature: | 1~40 degree |

| Operating temperature: | 1~50 degree |

| Inlet water hardness: | ≤12mmol/L |

| Outlet water hardness: | ≤0.03mmol/L |

| Regenerating resin should use NaCl, couldn't use iodised salt, calcium salt |

| Amanda Water Softeners Technical parameters | |||||

| Item No | Production capacity (m3/h) | Resin tank OD×H (mm) | Resin content (L) | Salt tank (L) |

| TMFB200 | 1 | 200×1100 | 25 | 60 | |

| TMFB250 | 1 | 250×1380 | 50 | 60 | |

| TMFB300A | 1~2 | 300×1400 | 75 | 100 | |

| TMFB300B | 1~2 | 300×1650 | 100 | 100 | |

| TMFB350 | 1~2 | 350×1650 | 125 | 200 | |

| TMFB400 | 2~3 | 400×1650 | 150 | 200 | |

| TMFB400H | 2~3 | 400×1800 | 175 | 200 | |

| TMFB500 | 3~4 | 500×1750 | 250 | 300 | |

| TMFB500H | 5~6 | 500×1950 | 300 | 300 | |

| TMFB600A | 6~8 | 600×1900 | 350 | 300 | |

| TMFB600B | 6~8 | 600×1950 | 375 | 300 | |

| TMFB600C | 6~8 | 600×2200 | 450 | 500 |

| Item No | Production capacity (m3/h) | Resin tank OD×H (mm) | Resin content (L) | Salt tank (L) |

| TMFB750A | 8~10 | 750×1900 | 525 | 500 | |

| TMFB750B | 8~10 | 750×1950 | 550 | 500 | |

| TMFB750C | 8~10 | 750×2100 | 625 | 800 | |

| TMFB750D | 8~10 | 750×2200 | 650 | 800 | |

| TMFB900A | 9~12 | 900×2100 | 850 | 1000 | |

| TMFB900B | 9~12 | 900×2200 | 900 | 1000 | |

| TMFB900C | 14~16 | 900×2400 | 1000 | 1000 | |

| TMFB1000A | 18~20 | 1000×2200 | 1100 | 1000 | |

| TMFB1000B | 18~20 | 1000×2400 | 1200 | 1500 | |

| TMFB1200 | 28~35 | 1200×2600 | 1600 | 2000 | |

| TMFB1500 | 40~50 | 1500×2600 | 2500 | 3000 |

|  |  |

|  |  |

1.Q:What's the valve used?

A:The valve we use is the world famous brand-Runxin valve.

2.Q:Is the resin a food grade or an industrial grade?

A:Food grade and industrial grade can be selected according to different customers' demands.

3.Q:Can resin be regenerated automatically?

A:Yes

4.Q:What's you warranty?

A:Our warranty is 1 year . But normally , our machine can work more than 5 years before repair.

5.Q: Are you pre-filter water softener Purification Manufacturer?

A:Yes, we are manufacturer of water softener Purification for 18 years in China.

6. Q:Could you make OEM service?

A:Yes, OEM is welcome.

7.Q: How to choose the model of pre-filter water softener?

A:Please contact us , good solution for you.

China

China