Coal Copper Gold Mine Citric Acid Separator Vacuum Belt Filter Press for Crystalline Slurry

Horizontal vacuum belt filter press is a very versatile liquid-solid separation device. It is used where a continuous separation is desired of solid from liquid stream. It can be used in process applications where the solid is the product or where the liquid is the product (and sometimes when both phases are the product).

How do you know if a vacuum belt filter press is right for your process? | Why use horizontal vacuum belt filter press? |

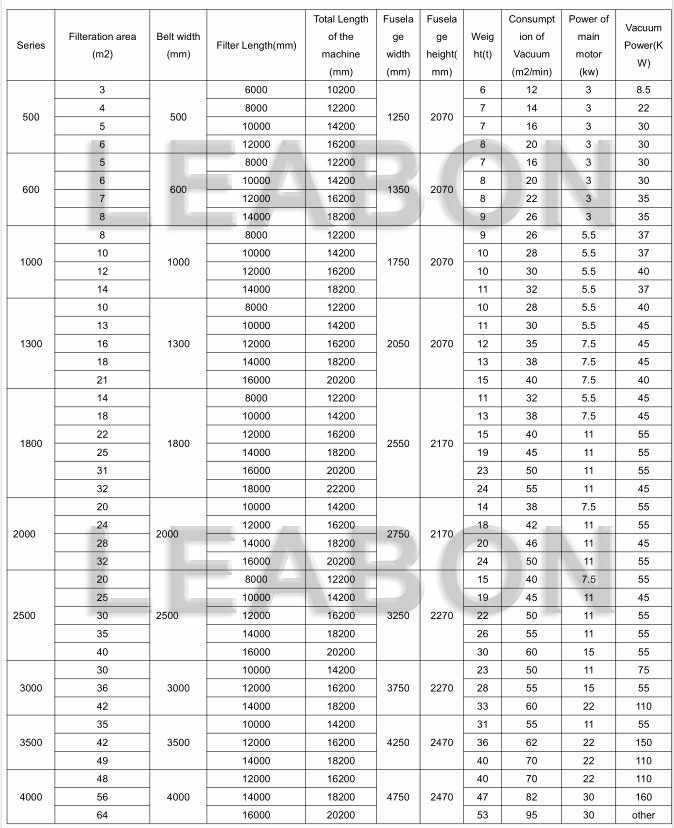

Does your process involve: 1 solid or liquid recovery 2 continuous separation of solid and liquid 3 cake washing for cake purity 4 Liquid filtrate recycling use Are you interested in: 1 minimal operator attention 2 low maintenance and expense 3 long service lifetime of a machine | Horizontal vacuum belt filter press offers: 1 Continuous operation 2 Large capacity of disposal 3 Ease of operation, minimal attention requirement 4 Simple, durable designs for low maintenance and long service life 5 Application versatility 6 Wide range of sizes |

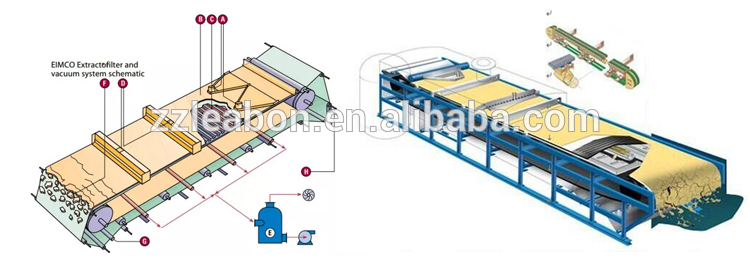

the introduction of the each parts in the machine

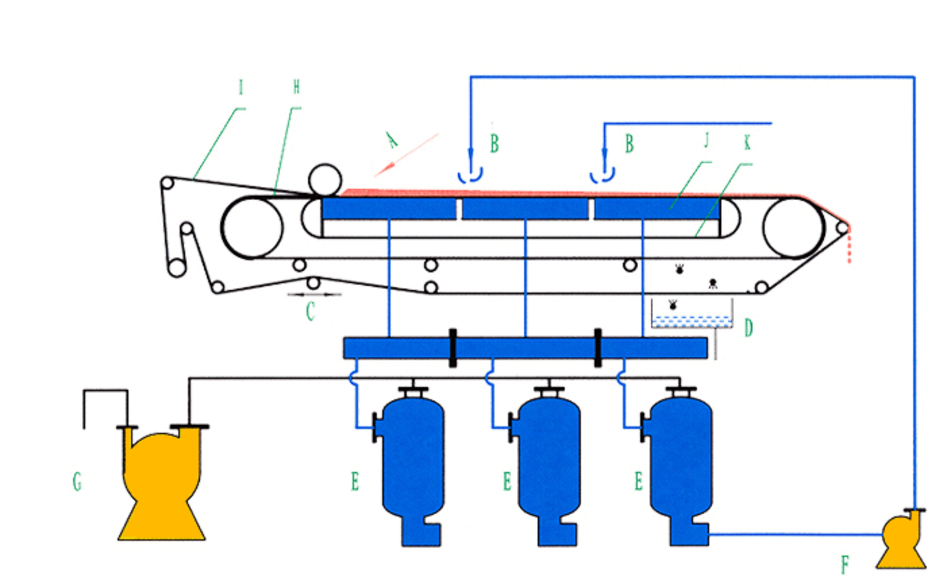

How does vacuum belt filter press work?

Step1: Feed slurry is distributed continuously on the filter cloth.

Step2: Vacuum sucks the liquid into the vacuum box through the filter cloth, but the solid remains on the filter cloth.

Step3: The vacuum pulls air through the filter cake and continues to remove moisture from the filter cake as the filter cloth moves forward.

Step4: The filter cake is washed by the washing device to get rid of impurities. Additional drying of the filter cakes follows the washing.

Step5: In the end, the filter cake is discharged from the filter cloth to a conveyor to the next process step.

Step6: The filtrate and air in the vacuum box flow through filtrate pipe and a gas-water separator.

Step7: The liquid stream is separated from the vapor stream by the washing pump.

Step8: The filtrate is pumped to wash the filter cake, so the water is reused.

Some components:

1. 1 Years Warranty (Exclude Wearing Parts).

2. We are in Biomass Production Line for Years, Good at this Business Fields.

3. Professional Service After Sale.

4. CE Certificate.

Nowdays,leabon machines have been exported to many countries in Europe,Asia,Ameriaca Africa and Australia.The customers range from individual to global distributors.No matter big or small machine, the expectations are always same:cost-effective and technologically advanced.This level of performance makes LEABON becomes one of the professional supplier in same trade.

TEL:+8637187535015 FAX:+8637187535381

Web:www.zzleabon.com

We sincerely hope to cooperate with more and more customers from the domestic and overseas for mutual development.

China

China