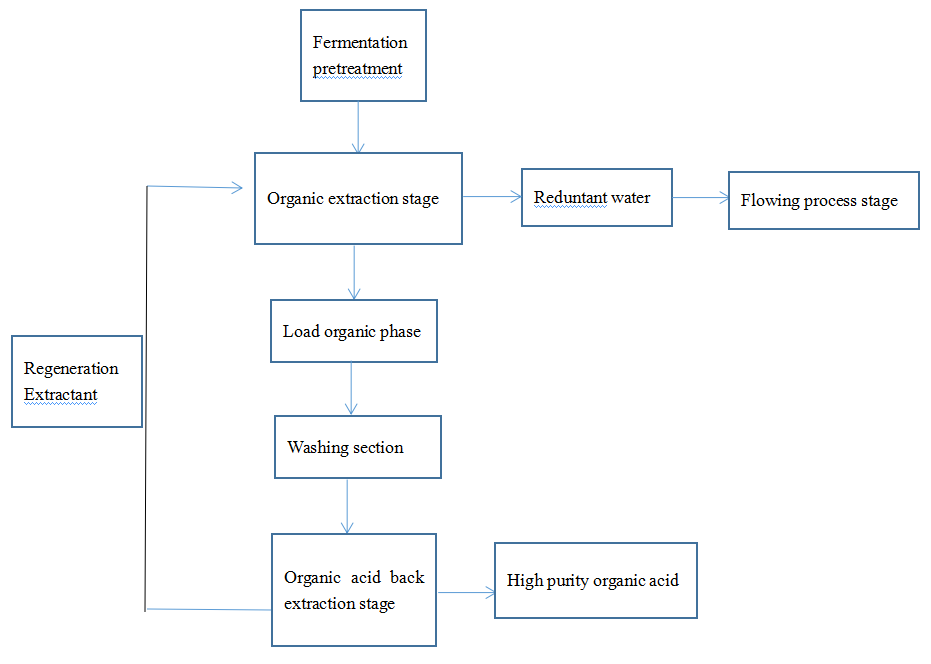

lactic acid centrifugal recovery by solvent extraction technology:

Solvent extraction technology used the differenct solubility in extraction system of separated component and other impurities, Citric acid was extracted to organic phase with extraction technology, and remove citric acid to aqueous phase with back extraction technology, back extraction liquor passed decoloring and enrichment of crystallization and get citric acid solid.

Solvent extraction technology with good sepration effect, continuous operation, and extractant could be recovery and used in extraction process again, to save operation cost, without waste acid, wast production, it is advatage of ecological stability.

lactic acid centrifugal recovery introduction:

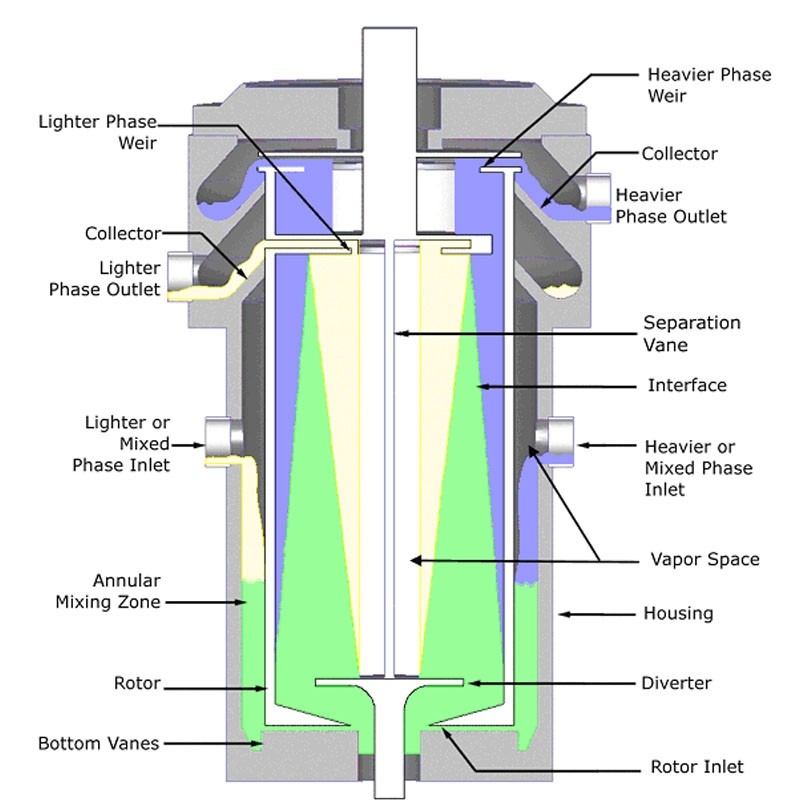

Countercurrent extraction processes is a new type, fast and highly efficient liquid-liquid extraction separation equipment, it is different with traditional extraction equipment such as mixer settler, extraction tower . Centrifugal extractor using the motor driven drum to reach high speed, the densities of different and not mutually mixed solution of two liquids in drum or blade rotation shear stress under complete mixing and mass transfer, and in high-speed rotation drum of centrifugal force under the action of rapid separation

lactic acid centrifugal recovery work principle:

1. Mixed and mass transfer process

The two solution according to a certain proportion mix together,the two-phase dispersing, two-phase solution obtained sufficient mass transfer, mixing and mass transfer process is completed.

| Model | Drum dia (mm) | Flux peak (L/H) | Inlet dia (mm) | Power(kw) | Size(L*W*H)mm | Weight (kg) |

| CWL50-M | 50 | 50 | DN20 | 0.18 | 400*400*800 | 18 |

| CWL150-M | 150 | 1000 | DN40 | 0.75 | 620*630*1150 | 120 |

| CWL250-M | 250 | 3000 | DN50 | 1.1 | 750*750*1400 | 460 |

| CWL350-M | 350 | 8000 | DN65 | 1.5 | 950*950*1688 | 680 |

| CWL450-M | 450 | 15000 | DN80 | 2.2 | 1000*1000*1800 | 880 |

| CWL550-M | 550 | 30000 | DN100 | 3.0 | 1200*1200*1760 | 1100 |

| CWL650-M | 650 | 60000 | DN125 | 4.0 | 1350*1350*1960 | 1800 |

| CWL800-M | 800 | 100000 | DN150 | 5.5 | 1600*1600*2400 | 2500 |

1. Equipment material will be chosen according dto the feed physico-chemical property, common used SS304/316L/904L, common composite material, fluoride material and so on;

2. Above table is general parameter, real device has a little devitation, please refter to the matched technological manual;

3. Above flux is under ideal condition, ratio of oil and water is their flux sum when 1:1.

lactic acid centrifugal recovery were used in the liquid liquid extraction or speration process which with little solid or without solid widely, mainly used in the flowing field:

1. Oil water separation( crude oil/heavy oil/diesel and so on except water, salt);

2. Pharmaceuticals( such as used for ethyl acetate, methylene dichloride, normal butanol, choroforom and so on);

3. Extraction of chinese traditional medicine;

4. Pesticide(malathion extraction and so on);

5. Bioengineering(nutrient solution extraction and interferon extraction and so on);

6. Chemical and fine chemical( catalyst extraction and so on);

7. Hydrometallurgy( used mutilstage extraction and back extraction and so on to extract nickel, copper, uranium and other rare metals);

8. Food( edible oil, spice, refined oil, food color and so on);

9. Perfume industry;

10.Printing and dyeing industry( printing and dyeing wastewater treatment and recycle);

11.Environmental protection( used multistage extraction and back extraction and so on technology to treat wastewater with phenol, oil-water separation of marine sewage, groundwater separation or extraction or purification and so on);

12. Cosmetics industry( to extract nutrient ingredient);

13. Liquid/two gas phase separation( to remove bubble in liquid phase and so on).

Zhengzhou Tianyi Extraction Technology Co.,Ltd.

Tianyi Extraction Tech group was built in 2005, and mainly devote to the research and development of liquid-liquid mixing and separation and application, integrated R&D&Manufacturing&Sales and reated project building.

Group Registered capital 10billion RMB, And there are more than 100 people, we obtained more than 20patents, We have more than 30sets production machinery equipment, and there is one extraction and application research center, one pilot-plant test(expanding test) base, two modern production and processing center.

Our product apply to fine chemicals, wet metallurgy, pharmacy, environmental protection and so on.

Gruop vision: Intergrity, Paratical, Innovative, Professional.Used advanced production equipoment, serious production control system, high quality technical research team and perfect service after-sales,dedicated to providing a full range of technical solutions for everye customer.

Mutullay benificial is our mission.

CML-M series lactic acid centrifugal recovery is our company R&D the 4th generation product, and have our own proprietary intellectural property rights, and our patent number( ZL2014205865573).

1. R&D, manufacture and sale on extraction and mixing equipment;

2. contraction on related supporting project, such as planning layout on extraction production line, installation and adjustion on extraction equipment, construction on related construction facilities.

3. Project test in every stage, such as lab-scale test, pilot test etc.

For more Citric acid centrifugal extractor message, please contact the flow information:

China

China