PVC EPS resin/Limestone/citric acid Tumbler screening machine

| Production introduction | ||||||||||||||||||||||||||||||||||||||||||

| YBS series tumbler screen is special designed to meet the requirement of large output and high precision screen,which is a highly efficient screening machine. As we all know,the simplest sieving way is focus your eyes on hands.Tumbler screen is just doing a mechanical simulation for this. It is the most effective to simulate the artificial screening exercise so far (screening accuracy, efficiency, and life of screen are much higher than common round vibrating screen,they always are 5 to 10 times ), comply with all range of fine and ultra-fine powder and particle materials, especially suitable for processing hard materials. | |||||||||||||||||||||||||||||||||||||||||

Applied fileds | ||||||||||||||||||||||||||||||||||||||||||

Tumbler screening machine is widely for fine powder and special materials, particularly suitable for materials which are difficult to classify.Details are as follows: Salt,EPS, citric acid, metallic silicon, glass powder, aluminum hydroxide, fertilizer, cellulose, crumb rubber, mineral etc… | ||||||||||||||||||||||||||||||||||||||||||

Features | ||||||||||||||||||||||||||||||||||||||||||

(1)The output of per unit area is up to five times; | ||||||||||||||||||||||||||||||||||||||||||

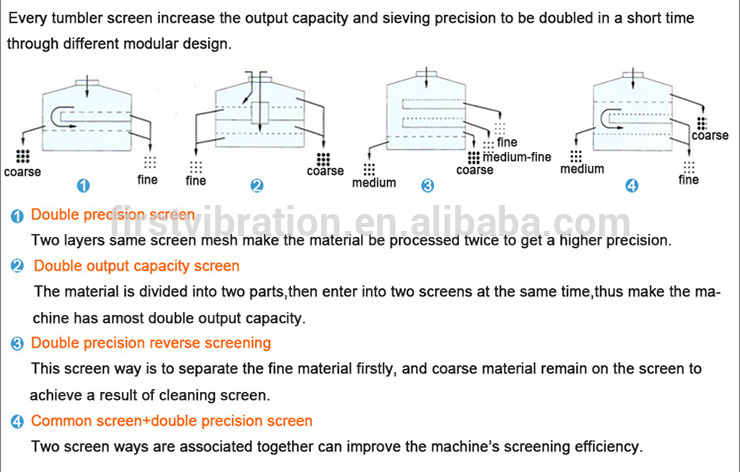

| Modular design | ||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||

| Different kinds of cleaning screen way | ||||||||||||||||||||||||||||||||||||||||||

| Cleaning mesh cloth by bouncing ball | This cleaning way is simple,easy operation and easy maintenance,which can be used for most kinds of material. | ||||||||||||||||||||||||||||||||||||||||

| Cleaning mesh cloth by turning brush | The turning brush is rotating under the screen,this cleaning way is widely used for spherical, crystallization and brittle material. | ||||||||||||||||||||||||||||||||||||||||

| Cleaning mesh cloth by ultrsound | This cleaning system is widely used for ultrafine powder with big output ability and some hard screening material. | ||||||||||||||||||||||||||||||||||||||||

| Technical parameter | ||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||

| How to choose a suitable model? | ||||||||||||||||||||||||||||||||||||||||||

If you don’t know how to choose a sieving machine for yourself,pls kindly answer the following questions,we will recommend you a suitable unit for you.

| ||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||

| Finished products in our store | ||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||

| Package and transport | ||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||

Welcome to contact with us.

|

China

China