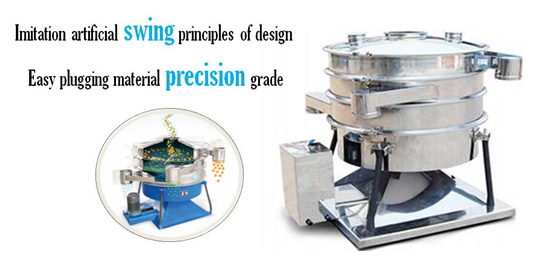

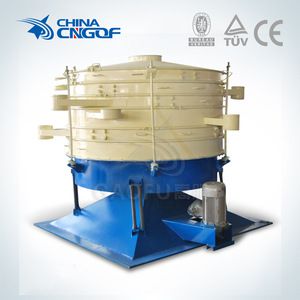

Swing screen machine/citric acid grading machine/food additive separator sifter

Technical and process related benefits

- Screening efficiency up to 99%.

- No particle destruction in sensitive products.

- High screening quality results in higher revenues for graded products.

- Higher specific screen load as compared to vibration systems.

- Stable screen motion even under full load.

- Tumbling movement indefinitely adjustable, resulting in precise control of residence time on the screen, capacity and screening efficiency can be coordinated and optimized.

- Screen motion is recordable, therefore the optimal operating data are reproducible at any time and result in constant product quality.

- Product specific mesh cleaning systems.

- Quick access to the screen inserts.

- Modular design permits various machine modifications.

- Dust tight, gas tight as option.

- Low-noise, easy to maintain.

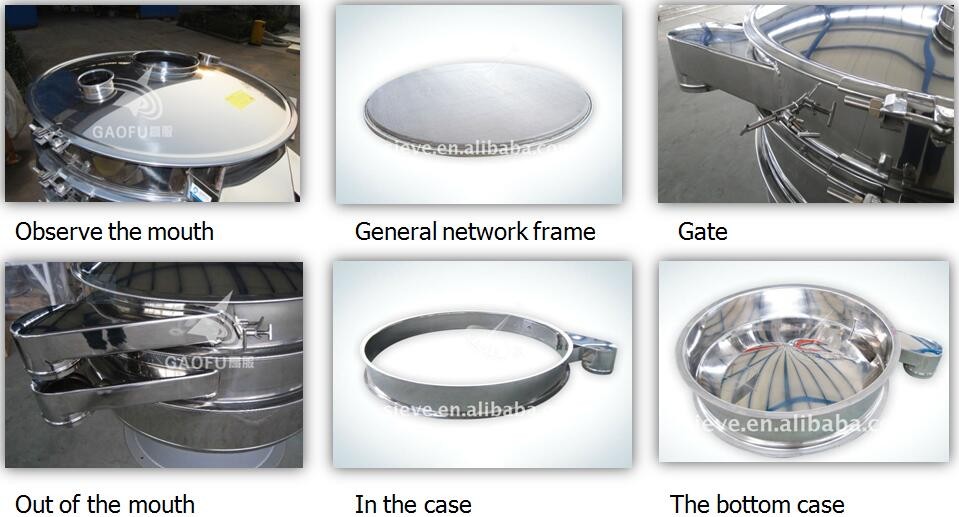

Options

- Internal/external screen frame Internal/external screen frame.

- Silicone sealing, mesh glue and flexible connection.

- Various mesh cleaning systems.

- Surface quality from glass bead blasted to electropolish.

- Dust and gas tight.

- Quick-action clamps.

- Mild and stainless steel modification.

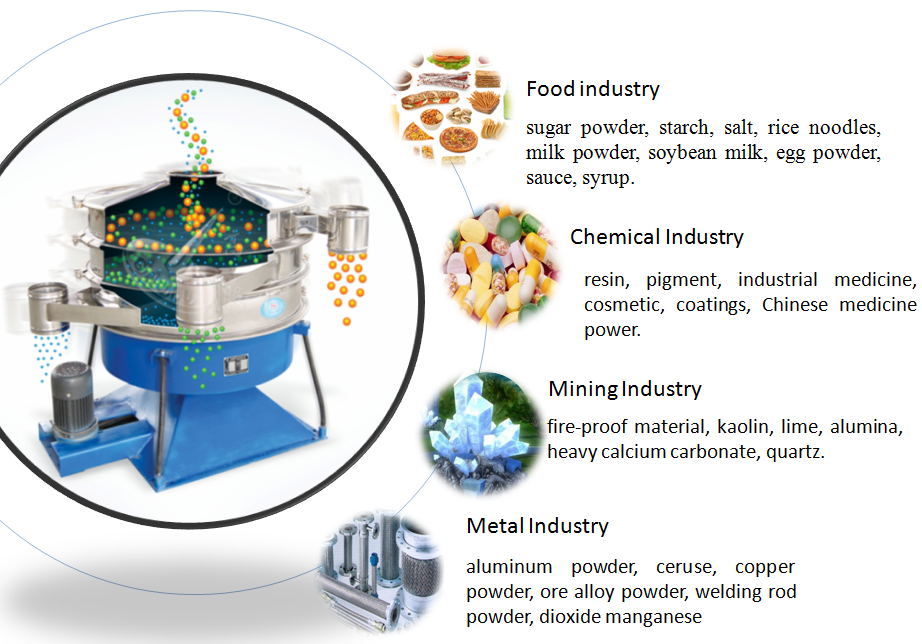

Applicable Scope

Related to the product

Product details

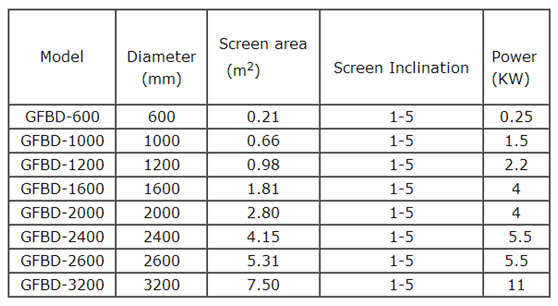

Technical parameters

Customer Worksite

The company has passed the ISO9001:2008, CE, BV certification.

Company Information

Gaofu company founded in 1982, 30 years of development history, gradually improve and integrated industrial chain;Main products include screening machinery, vibration equipment, crushed coal machinery, filtration equipment, dust removal equipment and other industries.With 56 national patents, is a design and production capacity of integrated machinery manufacturing company.

Our Team & Service

Basis service

1.Your sample material can be free analysis in our laboratory.

2.24 hours a week online & quick response within 12 hours.

3.Booking hotel and ticket for customers and Free transportation during visit our factory.

4. Production lead time and delivery time guaranteed.

Customized services

1.Professional R & D team to develop the new products as you requirements.

2.Help high-end customers to develop the local market

3.All packing and shipping can customized as per your requirements.

After-sale services

After customers received the goods,if have any questions or quality problems, Our customer service Dept. will be always available.

Customer Visit

Our customers came from different countries every year.

1.How is the quality of your products?

Our products are manufactured strictly according to national and international standard, and we take a test on every macchine before delivery.

2.Guaranteed:

If products’quality is not consistent with the description as we described or the promise before you place order, we promise 100% refund.

3.How about price?

Yes, we are factory and be able to give you the best price with good quality, and we have a policy that “ for saving time and absolutely honest business attitude,we quote as low as possible for any customer, and discount can be given according to quantity”.

4.Service and Payment Terms?

A. We usually accept T/T, L/C;

B. T/T: 30% in advance as down payment, the balance before delivery;

C. We take pictures of finished products before delivery.

Tell me the following questions, Then I can send you accurate quotation soon, including additional discount!

Your email address and telephone will not be shared or published!

The proper selection of the vibrating screen depends on the material, mesh size, output required, method of input, abrasiveness of the material etc:

1. Material : _____

2. Moisture:_____%

3. Capacity: :________kg/ hour

4. Screen layer:_______

5. Screen mesh size:______ mesh . ______ mesh. ______ mesh

6. Voltage:______V, Frequency:______HZ, 3 phase

7. SS304/316L stainless steel or Q235A carbon steel?

Contact a GAOFU professional-Amanda Lee today.

China

China