Brief Introduction

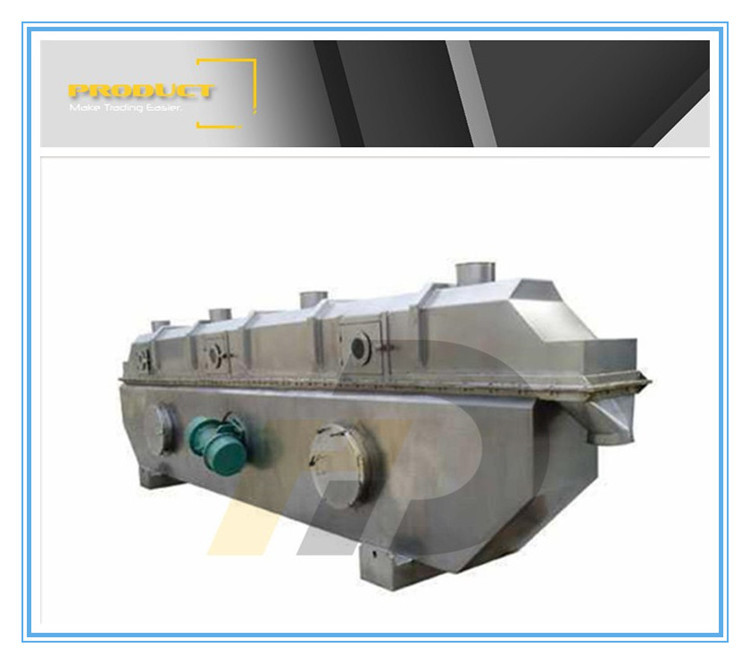

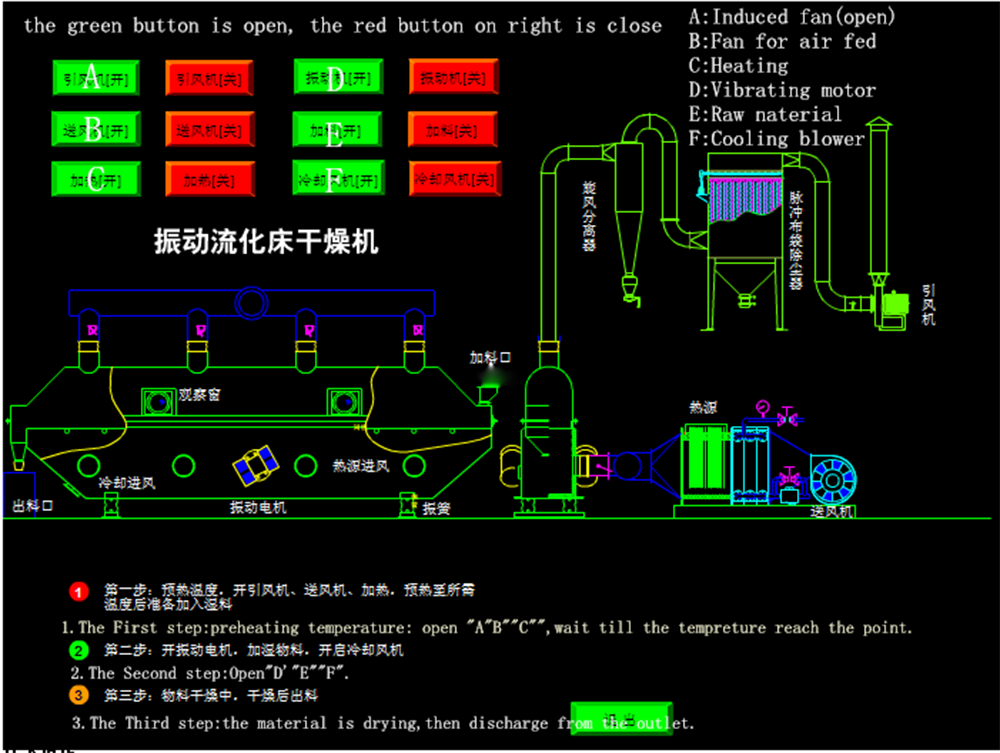

Fluid bed dryer is widely used for drying, cooling and damp decreasing (or carry out at the same time) for powder or granule materials. Material is fed into the machine from feeding inlet, and moves forward continuously along with the level of fluid bed under the action of vibration force. Hot air passes through fluid bed and carried out heat exchanging with damp material. Then the damp air is exhausted out by exhaust fan, some fine powder is collected by cyclone separator and dust remover, and dried product is discharged from discharging outlet.

Features

1. Use vibration motor as vibration source. It is smooth in running and convenient in maintenance. The noise is low and the using life is long.

2. The state of fluidization is uniform and no dead gaps and broken phenomenon.

3. It is better in adjustment and can be widely applied, The thickness, the speed of raw material moving inside and the change of vibration breadth can be stipples adjusted.

4. It makes little harm to the surface of raw material. So it can be used for fragile materials. If the granule is abnormal, the effect of process cannot be affected.

5. Fully sealed construction, effectively prevents cross infection between materials and air.

6. The efficiency of machinery and heat is high and 30-60% of energy can be saved than ordinary dryer.

Application

The machine is suitable for drying, cooling, humidifying of powder and granule materials in chemistry, pharmaceutical,

foodstuff, beverage and mining industries, also can be used for drying, cooling and humidifying simultaneously.

1. Chemical medicine: a variety of pressed particles, boric acid, borax.

2. Food materials: monosodium glutamate, sugar, salt, slag, seeds.

3. Materials can also be used for cooling, humidification.

Q:What is your main product?

A:We are a factory produces vibrating screen, conveying equipment,drying equipment,mixing equipment,pulverize equipment etc.

Q:What is the delivery time of your factory?

A: 15 days-20 days for general series products.

Q:What are your payment terms?

A:L/C,T/T,Western Union,Trade Assurance

Q: How do your after-sale service work if the product got damaged?

A: In warranty 12 months, our general after-sale service is changing the damaged parts for the customer, but if the damage could be repaired by slight cost, we would wait for the customer's bill for the fix cost and refund this part of cost.(note: Vulnerable parts do not include.)

Amy Pei

E-mail:sales_d at dhmachinery.com

skype no.:sales_d at dhmachinery.com

Whats app:8613460486527

www.dhmachinery.com

China

China