Tomato paste drum dryer price/drum set price/single drum roller

tomato paste drum dryer price/drum set price/single drum roller Production description

Potato residue/tomato paste (cassava residue, sweet potato residue,patata residue)is the subsidiary products of starch factory and alcohol plant. It Is rich in cellulose,hemicellulose and crude protein. The material amino acid composition is completed, the crude protein of the mycoprotein is as high as 40%-50%, It’saccelerated to promote animal growth.

Production house of tomato paste drum dryer price/drum set price/single drum roller

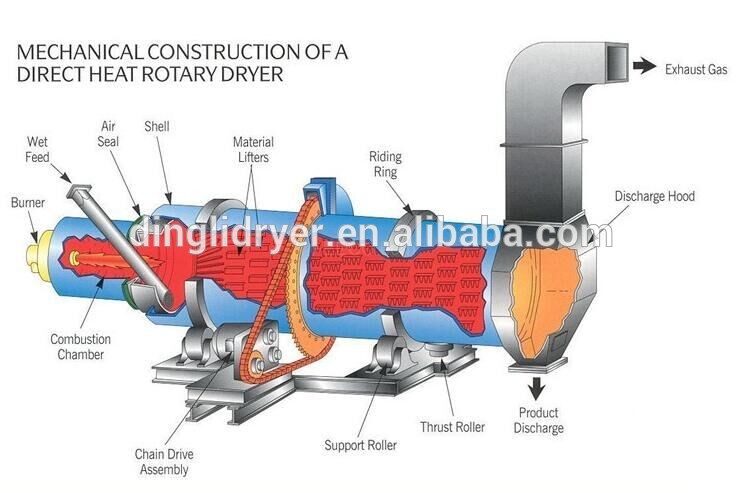

Tomato paste drum dryer price/drum set price/single drum roller Working theory

Material is constantly taken up and scattered by the rotary dryer machine inner layer lifting plate, so to meet spiral marching heat exchange.Material moves to the end of the inner lalyer, then come into the middle layer,

do counterflow drying.

Material is winnowed constantly, two steps forward andone step back. In the rotary dryer machine middle layer,the material fully absorbs heat from the inner cylinder, and also absorb the heat from the middle cylinder, at same time prolong the drying time. The material reach the best drying state. The material comes to the other end of the rotary dryer middle cylinder, then fall into the outter layer.

Material in the outer cylinder go ahead with rectangular and multi-loop way. The part meet drying effect move quickly then come out from the rotary dryer machine cylinder. Themoist material which doesn’t meet drying effect can’t move quickly because of itself weight. Material is fully dried in this rectangle shovelling plate, finally meet the drying purpose.

tomato paste drum dryer price/drum set price/single drum roller Structural features

1.Treating amount of rotary dryer machine is large, each equipment per day could deal with 80-200T fresh potato residue.

2.Good adaptability,rotary dryer not only for potato residue but also is suitable for vinasse, compound fertilizer etc, which is poor scattered and low reduction of moisture

3.Use rotary dryer cylinder dryer as the main drying machine, single structure,less breakdown, low maintenance cost, large production capacity And also could ensure that long time continuous operation.

4.The specially designed lifting board inside the rotary dryer machine cylinder make sure the potato residue drying effect

5.The rotary dryer machine adopts new unique sealing device,and match with with good thermal insulation system

6.Rotary dryer machine adopts stepless variable speed driven, the cylinder revolving speed could be adjusted easily according to different material moisture content, so get good drying effect

7.After the drying process, the potato residue dryer could be added with subsequent section such as crushing, mixing, granulation, packing etc. To produce potato residue pellet feed products

practical cases of tomato paste drum dryer price/drum set price/single drum roller

size | Φ1.4m×10m | Φ1.4m×13m | Φ1.4m×16m | Φ2.2m×10m |

capacity/day | 8T | 10T | 12T | 20T |

power | 34kw | 36kw | 32.7kw | 40.2kw |

coal consumption/t | 120m² | 135m² | 36m² | 64m² |

cost of labor | 3.4$ | 3.4$ | 3.4$ | 3.4$ |

plant area (W×L×H) | 5×15×3.7 | 5×20×3.7 | 5×25×3.7 | 6×35×5 |

Any requirement about tomato paste drum dryer price/drum set price/single drum roller , pls contact to get the professional scheme

China

China