Introduction

Cyclone Collector are often employed as an Initial Stage Collector to lighten heavy dusts loads before being sent to a Primary Stage Fabric Collector. By removing coarse particles from the gas stream, and allowing later stage Fabric Collectors to solely remove finer particles, these collectors increase the efficiency and service life of Fabric Collectors (Baghouses) and their Filters. Thus protecting your larger and most costly investment from unnecessary wear and tear.

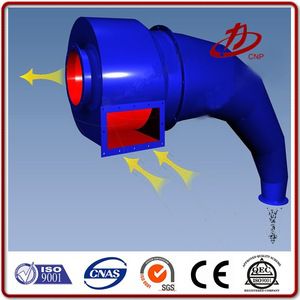

It often named after the cyclone weather phenomenon, are large funnel shaped sheet metal tubes connected to ducts often used in woodshops, machine shops, manufacturing plants, and powder processing plants. Dust and debris are sucked in at the top. Air containing fine dust blows out of the other side of the top, while chips and large dust particles fall out of the bottom into a drum or bin. Dusty exhaust air is either blown outside or filtered again using media filtration.

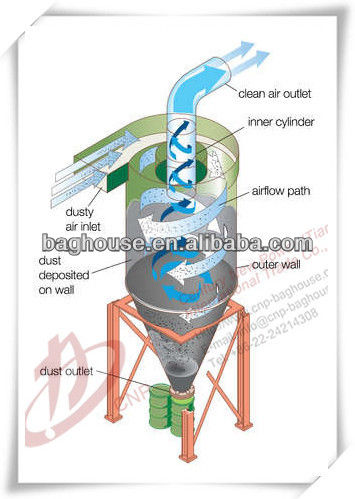

Working principle

As the dirty air enters the cyclone dust collector, it is forced into a swirling movement. This results in a centrifugal force acting on the dust particles suspended in the air stream. The particles, denser than the air, are forced to move outwards, towards the cyclone dust collector wall. They then fall downwards, towards the dust exit. The clean air is eventually directed towards the centre of the cyclone and leaves through the gas exit.

Cyclone dust collector efficiency is a function of the physical parameters of the particles and the design parameters of the unit. Cyclone efficiency increases with:

- Coarse particle size distribution

- Higher products specific gravity

- Lower gas density

- Smaller outlet diameter. An increase in pressure drop also results.

Characteristic

The Cyclone dust collector hasn't any moving parts. It's conenient for manufacture and management. With the same air volume, The cyclone collector is more smaller size, and the price is more cheaper. As the second dedusting and matched with bag filter, it can be installed vertically, also can be installed in a horizontal. So, it is easy to install and applicate. The cyclone collector efficiency of resistance is not affected for many sets of cylcone dollector in multiple using when processing the large dust gas air volume.

STRUCTURE COMPOSITION

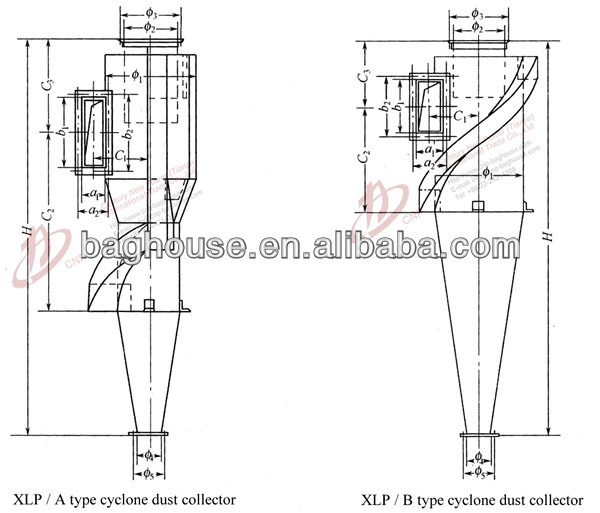

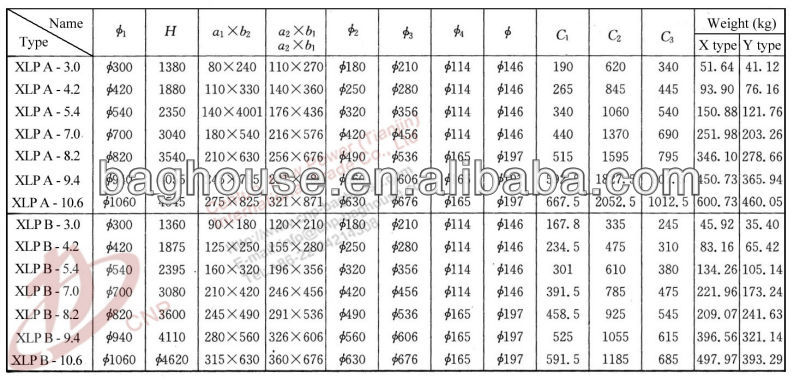

XLP type cyclone dust collector size:

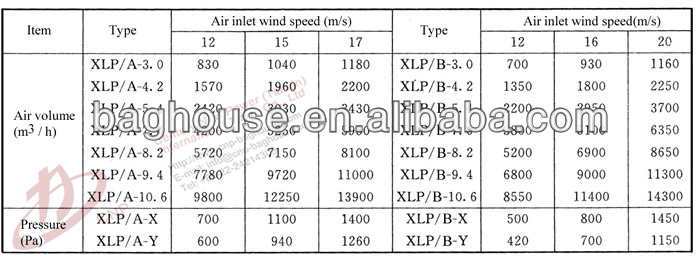

XLP type cyclone dust collector main performance:

Mine dust collection and secondary dust filtering the cyclone collector

********************

Please click the following product name to view more product details:

SINGLE BAG FILTER ROUND PULSE FILTER CENTRIFUGAL FAN REVERSE BLOW FILTER DUST COLLECTOR

FILTER BAG / FILTER CAGE SCREW CONVEYOR AIRSLIDE FABRIC / HOSE PULSE VALVE UNLOADER FILTER FELT

********************

We provide all kinds of standard export packing for cargo protection. The bag filter will be fixed on the container. The filter bag and cages will be fixed in corrugated box and steel framed structure.

1. Enquiries quickly reply within 24 hours.

2. After-sales service, rapid response, the engineer installation guide. The feedback problems will be replied within 24 hours. We can arrange professional engineers arrived at equipment location within 48 working hours for problem solved.

3. The dust collector design according to the specific condition of dust removal technology. The wind network project design for all system. To be the optimal structure design.

4. The lowest equipment price whole network in alibaba Welcome to rate of the price. If our price is higher, we will return twice of our quoted price difference to you. Please prompt before sign the contract with us. Due to our good faith principle.

5. The bag filter equipment over 20 years working life.

6. Associated with equipment spare parts, ensure the replacement parts within 20 years.

7. If accessories stop production or update, to ensure that the replacement parts can be normal use, and keep noticed one year before the spare parts stop production.

8. Ensure easy operation and absolutely no worries about future

CNP Co., Ltd. was founded in 2008, specializes in the field of air pollution control and bag filter, Including engineering design, planning, consulting, equipment research and development, manufacturing, sales, installation and commissioning, as well as production and services.

With national environmental design qualification and qualification certificate of foreign contracted projects, as well as certification of the IS09001, IS014001 and IS018001. Now we have become a much respected users-concerned PM2.5 dust control and industrial de-dusting solutions provider. We do contracting business of municipal solid waste incineration flue gas treatment system, electromechanical integration of environmental protection, total contracting capabilities of new technologies.

Since Five years ago, CNP has always regarded as our responsibility as to “Purify the atmosphere and benefit mankind”, adhered to scientific and technological innovation and introduction, digestion and development. So far, we have developed more than 30 sets of series over 400 kinds of specifications of bag filter, successfully undertake and complete total contracting of a variety of types of large, medium-sized dust-removal, desulfurization project.

Achieve an annual output of dust filter area of one million square meters. Products are sold domestically and also exported to nearly 20 countries and regions, including Japan,Korea, Singapore , Australia, USA,Brazil, Russia, Portugal,India, Vietnam , Bangladesh. Products are widely used in metallurgy,boiler,waste incineration , nonferrous metals, building materials, food,light industry, chemical industry, machinery casting,electronics industries and so on.

Based on the high starting point, CNO Co., Ltd., with a positive and upward pioneering spirit, will further create brilliancy as to technological innovation, intellectual property rights and independent brand strategy.

Summary of Information Requested

It is important to us that we find out what is important to you, and offer the most effective solution for your specific dust collector needs.

To accomplish that, we will need to know as much of the following information from you as possible.

How much CFM will be needed for the Baghouse Dust Collector?

What type of material will you be collecting? and how much dust do you usually dispose of in a day?

What is the bulk density of the material?

Approximately what air velocity (FPM) are you looking for?

Do you have an Air-to-Cloth Ratio in mind?

What is the Air Temperature projected at the inlet duct?

Is the material explosive? If so, do you need a spark detection system, explosion vent, or sprinkler system?

How many pick-up points will there be?

What is the static pressure you are projecting for the system?

Are you wanting us to supply the Inlet Duct, Pick-Up Hoods, Installation, or Fan?

Do you want a Rotary Valve or Double Dump Valve, and is a screw conveyor required?

What are the height and size requirements, if applicable?

Do you have a specific filter bag material and construction that you are looking for?

China

China