2014 Patented design Rotary Steam Drum Dryer 3.6*32m !

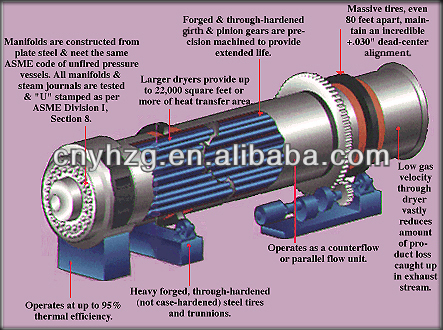

FEATURES of the Rotary Steam Drum Dryer

The YUHONG steam tube dryer offers the following features:

1. Mass processing

The number of heating tubes is large and the heat transfer area per unit volume is the largest of all the rotaly dryers presently available.

2. Easy operation

Large changes in processing quantity can be fully abosorbed, featuring ample retention time and simple adjustments. Only temperature of heat source needs to be controlled for drying operation.

3. Energy-saving

Thermal efficiency is extremely high especially for processing a large quantity of material at low temperature. Mechanistically, the driving power is smaller and also running costs are lower.

4. Low leakage

The special gas-sealing machanism seals the dryer to prevent both inert gas from leaking and air from flowing into the dryer. Therefore, solvent is recovered easily and inert gas emissions are lower.

5. Low pollution

Indirect heating minimizes inert gas emissions. Inert gas treatment system and deodorization system can be made compact

MODELS of the Rotary Steam Drum Dryer

The steam tube dryer have two different types, i.e., Type PD and Type CD, of which the most suitable dryer can be chosen according to the substance to be applied.

| Type PD | Type CD |

Operation method | Open air | Closed |

Ventilation method | Natural ventilation, exhaust fan | Carrier gas (N2, etc.) |

Product discharge method | From the chute around the shell | By a screw in the center of the discharge end |

Applicable materials | Not affected by exposure to air | Easily affected by expose to air |

Internal pressure of shell | Negative pressure (Approx. -50 mmAq) | Pressurized (+50-+500mmAq) |

Air seal | Simple seals, such as labyrinth, etc | Closed seals, such as gland, etc. |

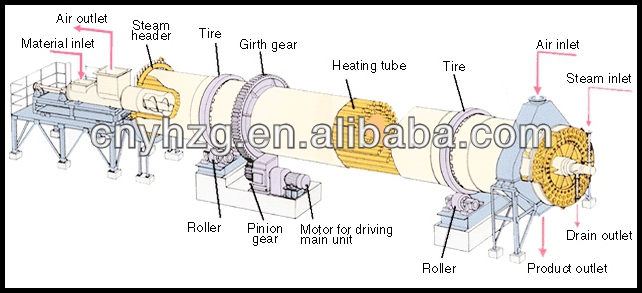

MECHANISM and PRINCIPLE of Rotary Steam Drum Dryer

Raw Material Flow

Raw material fed by the screw conveyor is dried by mixing in the rotating dryer, and is transported down along the inclined dryer, then discharged from the discharge chutes placed around the circumferential shell.

Steam Flow

Steam is supplied from a steam neck and distributed through the manifold to the heating tubes. Besides, considensed drain moves through the scope of the dryer into the manifold, then is discharged from the steam neck.

Inert Gas Flow

In the case of the counter-flow type, inert gas containing vapor flows concurrrently with raw materials and is discharged at the feed inlet of raw materials.

In the case of the parallel flow type, vapor is discharged at the product outlet.

In the case of the CD type, inert gas can be circulated as carrier gas, therefore solvent can be recovered easily.

Rotary Steam Drum Dryer EXAMPLES OF APPLICATION

Many types of resins, including polyethylene, terephthalic acid, polyacetal, polycarbonate, etc.

Foods and environmental wastes, such as gluten meal, corn fiber, corn germ, beer spent grains, sludge, lime, incineration ash, crushed beans, bean cake, etc.

Also see the table of treated materials.

Rotary Steam Drum Dryer STANDARD DIMENSIONS of STD

Diameter × length | Heat transfer area | Rotating Speed | Power |

965×7500 | 37.5 | 6 | 3.7 |

965×10500 | 53 | 6 | 3.7 |

1370×7500 | 74 | 5 | 5.5 |

1370×9000 | 89 | 5 | 7.5 |

1370×13500 | 133 | 5 | 7.5 |

1830×12000 | 194 | 4 | 11 |

1830×15000 | 242 | 4 | 11 |

1830×18000 | 291 | 4 | 15 |

2130×12000 | 312 | 3.5 | 15 |

2130×15000 | 390 | 3.5 | 18.5 |

2130×18000 | 468 | 3.5 | 22 |

2440×15000 | 484 | 3 | 22 |

2440×18000 | 581 | 3 | 30 |

2440×25000 | 807 | 3 | 45 |

3050×18000 | 921 | 2.5 | 45 |

3050×25000 | 1280 | 2.5 | 55 |

3050×30000 | 1536 | 2.5 | 75 |

3400×16500 | 721 | 3.1 | 132 |

3400×25400 | 1434 | 3.1 | 150 |

3600×26500 | 1590 | 3 | 250 |

4300×35500 | 3600 | - | 500 |

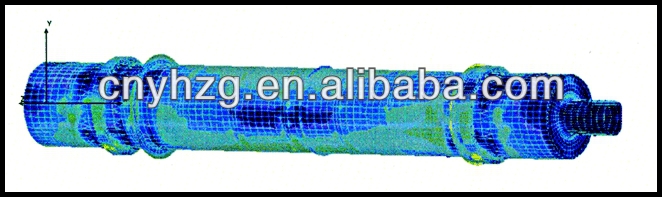

STRUCTURAL ANALYSIS of the Rotary Steam Drum Dryer

YUHONG adopts computerized strength analysis in the design of steam tube dryer.

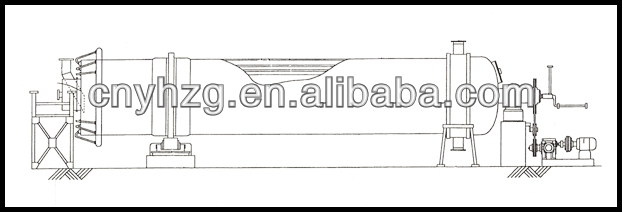

OST REDUCTION Rotary Steam Drum Dryer

The aim of the single-tire type is low pricing by keeping the most out of the functions of a stream tube dryer.

all equipments are naked or unpacked,and by loaded into container or bulk .and by sea or by train

China

China