Trust our experience to manage your business

centrifugal sieve /high efficiency cassava starch with very low price

We specialize in Cassava Starch Production line exporting and manufacturering.

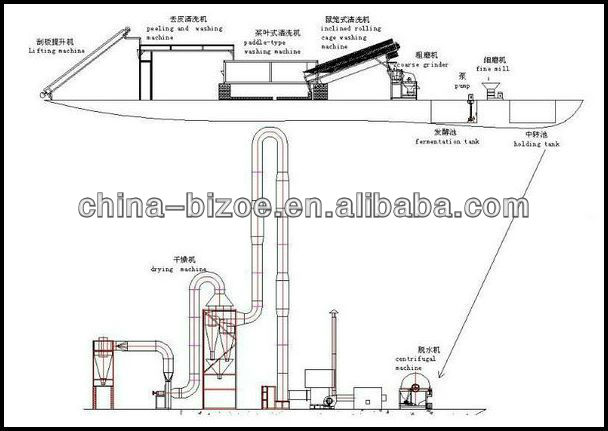

The processing technology is describing briefly as following: raw material washing, peeling off, general crushing, fine crushing, separating of residue and starch slurry, starch slurry refining, dewatering, airflow drying, dressing and packing.

> Washing & Peeling Section

To cassava, the material is sent to cage washer through scrape board to get the result of decontamination, cleaning and peeling . Then through a paddle-washing slot, material is sent to crash section.

We adopt the rasper to crash materials. Compared with traditional crasher, it has the large capacity, high starch dissociation degree features, which are essential to get high starch recovery.

> Milling and grinding section

Grinding clean cassava root into cassava slurry to make it easy dewatering and drying.

> Concentrating Section

The crashed material is sent to centrifugal sieve through pump to extract starch and separate cassava residues.

Centrifugal sieve group are 4 or 5 stages, the front stages is to extract starch and the last stage is to dewater the cassava residues. The whole stage adopts countercurrent washing to get the best results and saving water.

> De-hydrating section

Sending the fine slurry to dewatering machine to remove the moisture inside the slurry, and then send it to the air dryer.

Compared with other starch, it is more suitable for cassava starch to dewater by vacuum filter. Moisture content of dewatered starch is 38~40%. Wet starch is sent to drying system through belt conveyer.

> Drying section

Drying the dewatered cassava flour in the air dryer to get dry product.

Dried starch reaches sieving system. High efficiency cooling starch sifter is used to cool starch and get the best starch

viscosity.

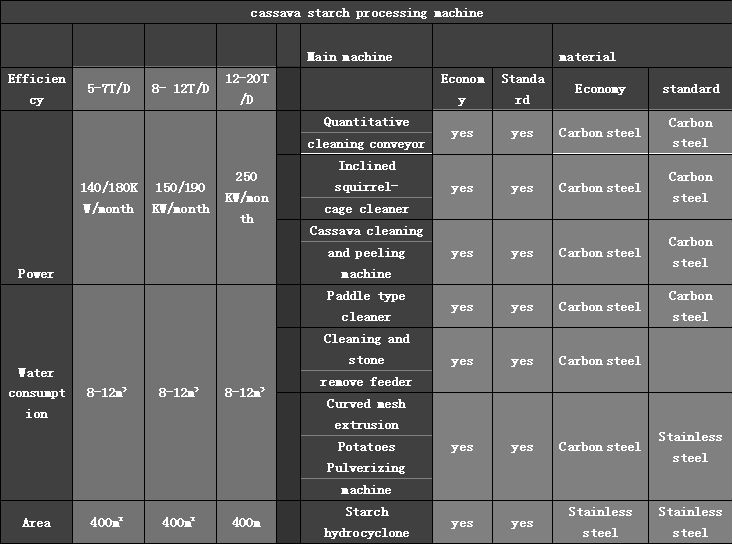

cassava starch machine main technical parameters

Advantages of Our Cassava starch line :

1. Advanced and reliable Processing technology.

2. Energy-saving water-saving labor-saving and little pollution. hot recycling close type production and the process water will be recycled .

3.Mostly machinery with fully stainless steel to be sure these is no corrosion.

4. Advanced surface treatment craft. Oil and dirty resisting.

5. Many various capacity option.

After-sale Service / What you can get :

1. Process know-how.

2. Pre-investment studies.

3. Feasibility / project reports.

4. Detailed engineering.

5. Turn key projects.

6. Equity capital participation.

7. Raw material testing .

8. After sales services .

Need More Details? pls send me e-mail or chat with me

China

China