China Automatic Potato Starch Making Machinery Centrifugal Sieves

Quality comes from power,professional makes perfect!-Zhengzhou Sida

- Potato starch is starch extracted from potatoes. The cells of the root tubers of the potato plant contain starch grains (leucoplasts). To extract the starch, the potatoes are crushed; the starch grains are released from the destroyed cells. The starch is then washed out and dried to powder.

- Potato starch contains typical large oval spherical granules; their size ranges between 5 and 100 μm. Potato starch is a very refined starch, containing minimal protein or fat. This gives the powder a clear white colour, and the cooked starch typical characteristics of neutral taste, good clarity, high binding strength, long texture and a minimal tendency to foaming or yellowing of the solution.

- Potato starch contains approximately 800 ppm phosphate bound to the starch; this increases the viscosity and gives the solution a slightly anionic character, a low gelatinisation temperature (approximately 140 °F or 60 °C) and high swelling power.

- These typical properties are used in food and technical applications.

The Introduction of Potato Starch Making Machinery

1.It is a physical separation process which makes the starch separated from the cellulose, protein, inorganic

salt and other material in fresh cassava tubers.

2.After crushing fresh cassava into mash materials, we add water in the mash and use a filter to remove the residue, and then we get starch milk with protein, a little tiny cellulose, and other impurities in it.

3.Because of starch is not soluble in cold water and has different specific gravity with water, specially designed machinery equipments can be used for separating starch from starch milk, and finally achieving the purpose of collecting starch.

The Capacity of Potato Starch Making Machinery

For the whole standard production line,the hot sales capacity include:

| 1. | 100kg per hour potato starch production line |

| 2. | 250kg per hour potato starch production line |

| 3. | 500kg per hour potato starch production line |

| 4. | 1000kg per hour potato starch production line |

| 5. | 2000kg per hour potato starch production line |

Note:

1.The capacity refers to ourput potato starch capacity

2.The machine will work continute for 24hours per day

3.We will also design the production line according to the customer's requirement.

The Package Of Potato Starch Making Machinery

1.For the whole standard production line,the package of the main machine is nude,but the important parts will packed by woven bags or other materials,the machine will be fixed on the container to keep safe.

2.For the spare parts,we will package in the carton first,then use the wooden case.

3.For single machine,usually is wooden case.

4.If the customer has other special requirement,please tell us before the shippment.

1) Pre-sale Service Of Potato Starch Making Machinery : |

a) Our salers will give a detailed introduction and explanation to the whole line. b) Our engineer will design the factory layout for you. c) We can offer you the OEM, basis on your request. |

2) After-sales Service of Potato Starch Making Machinery : |

a) We can offer the Turkey Project for your request. b) We offer you the whole factory design and machines' installation drawing c) You can sell our worker to our factory for learning before the goods shipping. d) We will offer machine operation training and guide for free when machine being installed. e) One year warranty. |

The Factory Of Potato Starch Making Machinery :

Zheng Zhou Sida Agriculture Equipment Co.,Ltd Established in 1994, we specialized in starch/flour field for more than 20 years. Recent years, we expanded our markets and start to the cassava/yam roots machines. Our machines have been exported to more than 15 countries, like Gabon, Nigeria, Malaysia etc,. and owned a high reputation in this field at home and abroad.

The Team Of Potato Starch Making Machinery :

1.Strong and vigorous technological force member.

2.Abundant theory and practical experience.

3.The zealous service and fast reply.

4.The scientific management system.

The Work Craft Of Potato Starch Making Machinery

1.Frist process is transportation and cleaning:

Collect the fresh cassava from stock ground, and transported by the conveyor belt to peeling machine for peeling and stone removing.After firstly remove the impurities on the surface, the fresh cassava is transported into washing process. After washing twice by trough conveyor and roller, the sediment and impurities on the surface of fresh cassava have been basically removed, and peeling rate can achieve 80%. After cleaning process, the cassava will be transported into the crushing process

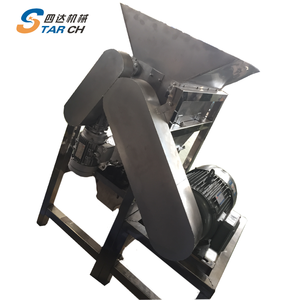

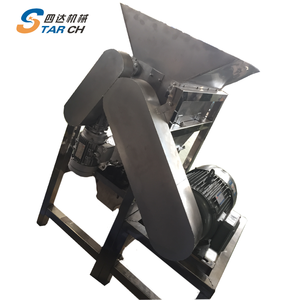

2.Second process is crushing

Clean cassava will be broke into pieces by flying hammer type grinding machine in order to break the organizational structure of cassava. So that small starch granules can be disintegrated from the cassava root. Water plays the medium here. After twice crushing, cassava becomes slurry. The starch slurry after the first crushing can pass through 6-8mm puree sieve. The starch slurry after twice crushing can pass through 1.2to1.4mm puree sieve. The starch is basically free and becomes a mixture of pulp residue, then pumps it into the sieve for separation.

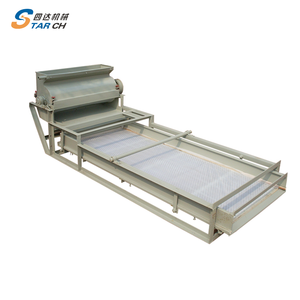

3.Third process is filtering

Residue slurry mixture passes through four vertical separator to be separated cassava waste will be transported to the residue filed.And the starch extraction can already meet the standards of products only with protein, sediment and other organic and inorganic impurities to be proceeded in next process.

4.Fourth process is separating and concentrating

Starch will be pumped through the sediment remover to remove inorganic impurities. And then into the first disc separator, and then into the second disc separator. The main function of first disc separator is to remove protein, and the main function of second dis separator is to concentrate to be dehydrated. After the above treatment process, starch basically reached the requirements of the finished product. Following processes are dehydration, drying sections.

5.Fifth process is dehydrating

Concentration of starch out of disc separator is generally 18to20. After centrifuge treatment, the water content of starch deceased from 60% to 38to40%; dehydration of water( containing about 1 to 5% starch) continues to be concentrated in the disc separator. The wet starch will be transported to the air dryer treatment through the screw conveyor.

6.Sixth Process is drying and filtering

Air drier is a saturated steam which heats air through the heat sink, The starch will be heated by the hot air drying to achieve the dry purpose. Negative pressure, no dust and energy saving is throughout the system. After air drying, the starch water content is between 12to14% of the finished product standards. To ensure the fineness of the finished product can meet the standards. We lso need to check the screen to prevent the starch after finished the process of agglomeration in the drying, so as to ensure that the final product can meet the standard.

7.Seventh process is packing

After been screening examination; qualified strach will be measured and packed. According to different requirements, we can pack them into 25kg or 50kg

If you are interested in Potato Starch Making Machinery ,Please Feel Free to Contact with us By:

Name | Rose Wang |

Trade Manager | cn1512179920 |

Mobile | 0086-13700841969 |

0086-13700841969 | |

0086-13700841969 | |

QQ: | 1767039183 |

China

China