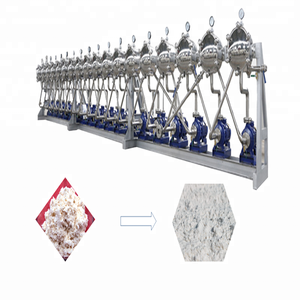

Cassava starch sieving machine

Cassava starch sieving machine include centrifuge sieve and fine fiber sieve.

Centrifuge sieve is a machine with a part that spins around to separate substances, for example liquids from solids, by forcing the heavier substance to the outer edge. It is mainly used for separating the fiber and starch slurry after crushing. Stainless steel structure ensures food safety, and the precision grade of dynamic balance of sieve basket is G6.3 to ensure stable operation.

The main technical parameters of centrifuge sieve:

Model | ZXS650 | ZXS800 | ZXS850 | ZXS1000 | ZXS1100 |

Diameter(mm) | 650 | 800 | 850 | 1000 | 1100 |

Power(kw) | 7.5-11 | 11-15 | 22-30 | 30-45 | 30-45 |

Weight(kg) | 1000-1200 | 1400-1600 | 1800-2000 | 2000-2200 | 2300-2500 |

Cassava starch sieving machine

The Operation principle of fine fiber sieve :

The product, fed by a dispenser or pneumatic conveyor, is entered into the barrel through a screw conveyor that regulates the flow to the sieving room. A rotating shaft with shutters spreads the product on the walls of the cylindrical sieved meshes by applying centrifugal force.

Fine fiber sieve for starch separating is mainly used for the removal of fine fiber in crude starch with high throughput and low energy consumption. The operation principle of fine fiber sieve for starch separating is its own gravity and own centrifugal force function by screen mesh inside them.

Technical parameter table:

Model | Drum diameter (mm) | Main shaft Speed(r/min) | Power (kw) | Dimension (mm) | Weight (t) | Capacity (t/h) | Roller Length (mm) |

DYXS-100 | 1005 | 21 | 3.0 | 4300×1380×1610 | 2.5 | 2-4 | 3300 |

DYXS-2×95 | 950 | 21 | 2.2×2 | 6000×1550×2300 | 3.8 | 3-6 | 5000 |

Cassava starch sieving machine

Category: Cassava starch sieving machine

Features of fine fiber sieve

1. Full stainless steel body structure, no material corrosion.

2. Sieve made of stainless or nylon.

3. Advanced surface treatment technology ensuring the good looking and resistance of oil and dirty.

The advantages of Cassava starch sieving machine are:

(a) Easy for installation and maintenance

(b) Low moisture content in dewatered product

(c) Good technical index

(d) Higher throughput

(e) Small footprint

The features of cassava starch sieving machine are:

(a) Low power consumption

(b) Big capacity

(c) Stable operation

(d) High starch extraction rate

OUR COMPANY

Henan Doing Mechanical Equipment Co., Ltd, is located in Zhengzhou city, Henan province, China. Doing company is an enterprise integrating engineering, R&D, equipment manufacturing and installation, project contracting, technical services and international trading etc. We are mainly engaged in starch and syrup processing plant, cassava processing plant, contains its stand-alone device. also gluten machine.

Our company is a professional R&D team, with advanced technology, powerful manufacturing ability. Our factory covering an area of33,335 square meters, with an annual production value of $8 millions, we own more than 30 senior technical engineers majored in starch and syrup technology, electric engineering, automation and machinery. Doing company focus on developing new products and technology. On the basis of making syrup from starch, we introduce the technology that using raw grains(rice/broken rice) to produce glucose/fructose/maltose syrup directly. We have undertaken to completed a number of major engineering and technical service abroad, equipped with modern installation equipment and the most professional installation team with rich experience, we guarantee the stable running of all projects.

OUR SERVICE

1.We can appoint specialized after sale service staff to your country for installation and debugging the equipment.

2.Train operating personnel.

3.All the machines will be checked OK before delivery.

4.Warranty for 12 months.

5.We provide technical support in overseas.

OUR PRODUCT

Our products sell well all over the world. Our machinery have been exported to Nigeria, Ghana, Tanzania, South Africa, Thailand, India, Uzbekistan, Russia, Kenya, Indonesia, Cameroon, Liberia, Pakistan, Bangladesh, America, Egypt, Brazil, Mexico and other countries and regions.

Accepted Delivery Terms: FOB, CFR, CIF, EXW, FAS, CIP, FCA, CPT, DEQ, DDP, DDU, Express Delivery, DAF, DES

Accepted Payment Currency: USD, EUR, JPY, CAD, AUD, HKD, GBP, CNY, CHF

Accepted Payment Type: T/T, L/C, MoneyGram, Credit Card, PayPal, Western Union, Cash, Escrow

Nearest Port: Qingdao, Shanghai, Guangzhou, Ningbo

1. Q: Are you a trading company or a manufacturer ?

A: We are a manufacturer, which has long experience in this industry.

2. Q: How can I get to your company ?

A: You can get a flight to CGO. We are just about 40- 50mins away from this Airport.

3. Q: How long is your guarantee ?

A: One year

4. Q: Will you send engineers to install the plant?

A: yes, but at an extra cost payable by the customer.

5. Q: Do you have some foreign customers using your equipment?

A: yes, we have our company has established business relationships with customers in Nigeria,Ghana , South Africa, Ukraine, Vietnam, Pakistan.

China

China