DGS Series Tube Bundle Dryer

Specifications

1. it can be used in chemical industry,light industry,pharmacy industryand others

2. stable preformance

3. big volume

4. high efficiency

Product Description

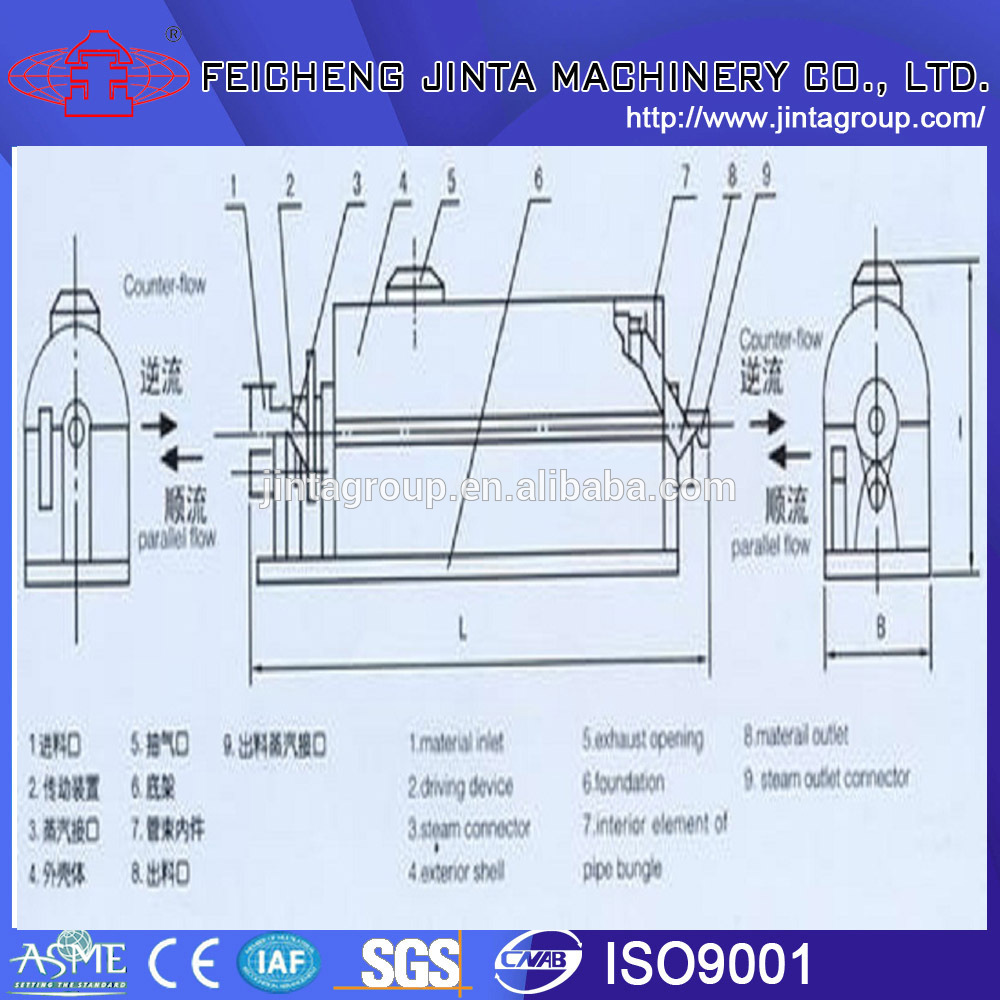

DGS Series Tube Bundle Dryer is a kind of drying equipment adopting thermal conduction and heat radiation to conduct the heat, the material inlet, returning and outlet of which can be accomplished continuously.

Usage

It can be widely applied in the drying of material with high moisture in chemical industry, light industry and pharmacy, which can adjust the drying time according to material features and moisture requirements, with the features of high automation, clean environment and steady operation.

Specification & Technical Parameter Table

Model No. |

HE Area |

(KW) Main Drive Power |

Design Pressure |

Steam Moisture Ratio |

Overall dimension |

L*W*H (mm) | |||||

DGS--80 | 80 | 7.5 | 0.7 | 1.4~1.5 | 7200×1600×2000 |

DGS--100 | 100 | 7.5 | 0.7 | 1.4~1.5 | 7400×1800×2200 |

DGS--150 | 150 | 11 | 0.7 | 1.4~1.5 | 7600×2000×2300 |

DGS--210 | 210 | 11 | 0.7 | 1.4~1.5 | 7800×2100×2550 |

DGS--250 | 250 | 15 | 0.7 | 1.4~1.5 | 7800×2400×2600 |

DGS--300 | 300 | 18.5 | 0.7 | 1.4~1.5 | 8200×2500×2600 |

DGS--350 | 350 | 22 | 0.7 | 1.4~1.5 | 8500×2600×3100 |

DGS--400 | 400 | 30 | 0.7 | 1.4~1.5 | 8500×2800×3320 |

DGS--500 | 500 | 37 | 0.7 | 1.4~1.5 | 9500×2800×3320 |

DGS--600 | 600 | 55 | 0.7 | 1.4~1.5 | 10000×3000×3550 |

DGS--800 | 800 | 75 | 0.7 | 1.4~1.5 | 10700×3200×3900 |

DGS--1000 | 1000 | 90 | 0.7 | 1.4~1.5 | 11000×3600×4100 |

DGS--1200 | 1200 | 110 | 0.7 | 1.4~1.5 | 11500×3800×4400 |

DGS--1500 | 1500 | 160 | 0.7 | 1.4~1.5 | 13000×4000×4600 |

Designed capability

1). We own Design License of Special Equipment D1 & D2 Class; Manufacture License of Special Equipment A2 Class; Design License of Special Equipment GC Class.

2).Our company achieves more than 20 patent certificates on distillation, DDGS, and other fields.

3). Our company owns ASME certification, ISO 9001 Quality System Certification, ISO 14001 Environmental Management System Certification & GB/T28001 Occupational Health and Safety Management System Certification.

After-sales Service

1). Our company can provide a sophisticated product after-sale service and can ensure the implementation, maintenance and commission of projects.

2). We can reach the project site after receiving the user’s notification.

International Exchange and Cooperation

JINTA is the largest designer and manufacturer of alcohol, fuel ethanol and DDGS equipment machinery and other chemical equipments in China. Our market of alcohol equipment in China keeps over 60% in the past 3 years and our products has been exported to more than 30 countries such as Australia, Argentina, Brazil, Russia and etc. We can develop different programs according to customers' raw materials and annual production and have advanced process technology, especially in energy consumption.

Packaging & Shipping

Contact us

Any questions, feel free to contact us!

China

China