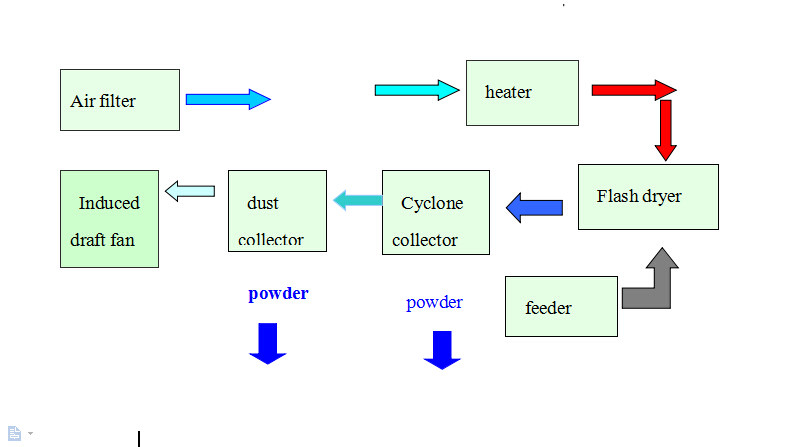

The hot air be put into the flash dryer tower from the bottom of dryer body air inlet, it will be with the high speed air flow all rise in the dryer tower ,at the same time we can adjust the annular space

Depend on the different kind of materials, let the air speed goes in the best suitable state.

The material with High speed rotary motion under the impact of airflow and drive dispersed quickly. However the big size granulate and wet particular clusters cannot crush with high speed rotary motion, so it will fall into the crushing plant under the effect of gravity forcibly broken and particulates. and then with the high speed air flow going up and finish the drying process.

The rotor at the conical base of the drying chamber fluidizes product particles in a drying-efficient hot air flow pattern in which any wet lumps are rapidly disintegrated. Using the heat from the airstream, the material dries as it is conveyed. Product is separated using cyclones, and/or bag filters. Typically, cyclones are followed by scrubbers or bag filters for final cleaning of the exhaust gases to meet current emission requirements.

Airborne, fine particles pass through a classifier at the top of the drying chamber, while larger particles remain in the air flow for further drying and powdering

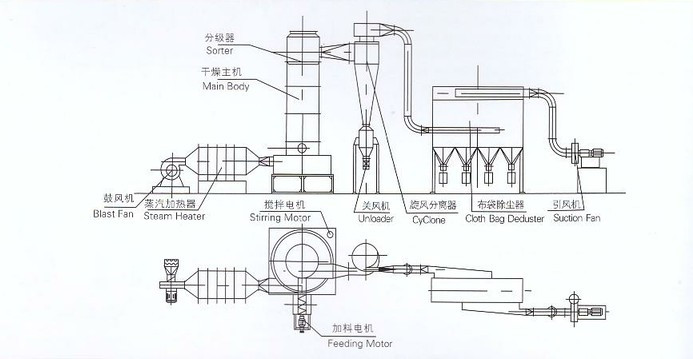

1. Adopt 2 lines tangential air enter into volute at the best position,it will improve or remove blind Angle of wind and also the wind in the weak

2.Be good at control the powder's moisture,fineness,and hold time.for control the speed coordinating and unifying at spinning disk work with wind-enter ,it can ensure the outlet wind with low temperature,it will also reduce the energy consumption.

3. The special alloy steel be used in the rotary blade,the layout structure with unique,it have the character of small erosion,contact surface wide,cutting force strong.

4. Adopt the newly leak-proof structure,the main engine bearing life will be delay,and the bearing black with the cooling device.

5. In order to ensure the powder water content less than 0.5%,so increase the height than the original basis ,it also equip with spinning disk,it will make the powder quality and particle size meet with your requirement.

Due to the gas-solid corresponding relative velocity big,even though the mix temperature around 80~90℃,the powder temperature still on below 45℃ condition,it will help to packing and save energy.

| Model (XZG) | 2 | 4 | 6 | 8 | 10 | 12 | 16 | 20 |

| Diameter of chamber (mm) | 200 | 400 | 600 | 800 | 1000 | 1200 | 1600 | 2000 |

| Air amount (m³/h) | 350-500 | 1150-2000 | 2450- 4500 | 4450- 7550 | 7000- 12500 | 10000- 20000 | 18000-36000 | 28200- 56500 |

| Evaporate capacity (kg/h) | 12-17 | 40-70 | 80-150 | 150-250 | 230-4250 | 300-600 | 600-1000 | 1000- 1500 |

| Max power (kw) | 10 | 20 | 40 | 65 | 85 | 105 | 150 | 230 |

| Max height (mm) | 4000 | 4800 | 5800 | 6.5 | 7.1 | 7.8 | 8.8 | 10.1 |

| Occupied area (m²) | 15 | 20 | 28 | 35 | 40 | 52 | 80 | 150 |

1.To effectively control final moisture content and fineness by spinning disk and the inlet wind speed.

2. The Spinning blade use the special alloy steel, which With less wear, wide contact surface, big cutting force etc

3.it is good at in deal with heat-sensitive materials, there are Cooling water protection device in the high temperature area, it avoid the material go to Coking discoloration in success.

4. Small system resistance, high thermal efficiency, good operating environment, the intensity of labor is low

5.The body tower uses new type seal structure, Extend bearing life cycle, and the Bearing casing also with a water circulating cooling device.

The flash dryer for fly ash.

This is flash dryer was exported to the Korea,which evaporate amount reach to 32.5T/h,the electric+Oil to be as the heat source.the most famous be fitting in drying filter cake form material.

The flash dryer for aluminium

This is flash dryer was exported to the Canada,which evaporate amount reach to 10kg/h,the electric to be as the heat source.the most famous be fitting in drying filter cake form material.

The pilot flash dryer.

This pilot flash dryer are popular used in pilot plant ,the customer feed the filter cake material into it for testing ,

to know much more about the

materal's character.the evaporate amount only 5kg/h,the electric to be as heating source .

1. Chemical Industry:

white carbon,amino acid,catalyst,dyestuff intermediate,sodium fluoride,compund fertilizer,etc.

2. Plastics and resin:

AB,ABS emulsion, uric acid resin,phenolic aldehyde resin,urea-formaldehyde resin,polythene,etc.

3. Food Industry:

oats,chicken juice,coffee,instant dissoluble tea,protein,soybean,peanut protein,hydrolysate,etc.

4. Sugar:

corn syrup,corn starch,glucose,pectin,malt sugar,sorbic acid potassium,etc.

5. Ceramic:

aluminium oxide,ceramic tile material,magnesium oxide,talcum,etc.

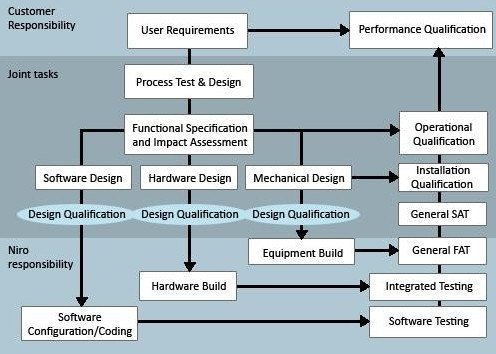

1. Design and production

We solicit buyers opinions widely at the design and production stage of equipment; especially at the stage of plan and elevation arrangement, we give full consideration to buyers' site conditions and public engineering conditions, and pay concurrent attention to the optimum combination when assuring the quality of equipment.

2. Installation and commissioning

After the equipment is delivered to buyers factory, we will dispatch full-time technical personnel to instruct buyers' installation and to take charge of commissioning until normal use of the equipment.

3. Training

Before buyers use our equipment normally, our commissioning personnel will organize buyers' relevant personnel to accept training, which covers the maintenance and care of equipment, timely repair of common faults, and procedures for operation of equipment.

4. Warranty

We provide one-year warranty for our equipment. For damage of equipment arising from non-artificial factors within the warranty period, we will provide repair service for free; and for damage of equipment arising from artificial factors, we will provide repair service in time and collect corresponding cost.

5. Maintenance and period

For damage of equipment after expiration of warranty period, we will provide on-site repair service within 1week for enterprises inside/outside the province after receiving buyers' notification. The service provided after expiration of warranty period is fee-based, and flat cost will be collected each time when the service is provided.

The spray dryer for sodium silicate.

This is spray dryer are customized by Slovenia, the evaporate amount reach to 2500 kg/h,the electric+oil to be as heat source,it is used widly in chemical filed.

Spray Dryer for instant coffee.

YPG-1800 ,exported to the Malaysia.

Spin Flash Dryer for fly ash.

XZG-3,exported to the Korea.

Mesh Belt Dryer for Onions.

DW5-2x9 ,exported to the Kazakhstan

China

China