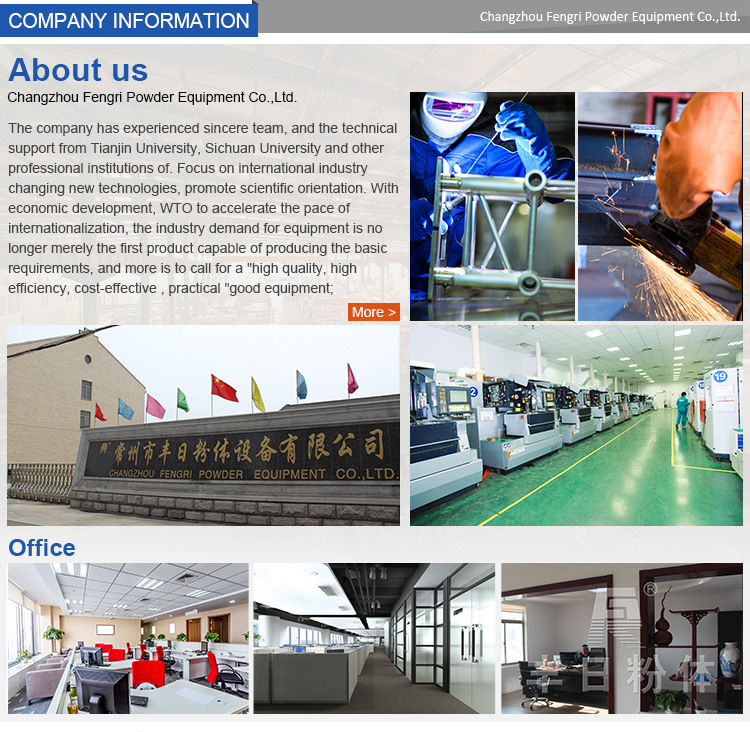

FG0.9 revolving vaporization flash air stream dryer for starch

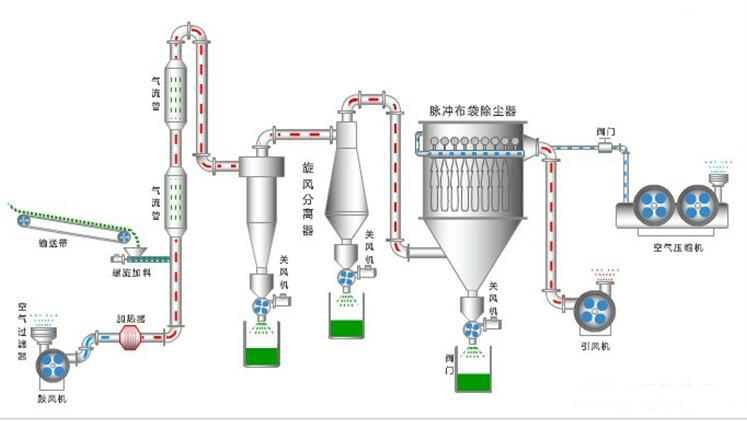

It is equipped with fan that has the function of dispersing.So it is suitable for heat sensitive raw material specially.The impeller to fan with high speed can crush the wetted and blocked raw material till dispersing.During the period of dispersing,it is stirred and mixed.Then the raw material and air are lowing parallel.With the equipment,raw materials that are blocked filter cake but belong to the raw material having moisture on its surface, Its content of moisture should be less than 40%.If the amount to be treated is large or the moisture requirement of finished products should be less than 15%,two grades drying can be used.If the moisture of raw material is between 40% and 60%,the feeder is difficult.It is necessary to adapt mixer.Through the method of mixing dry raw material into it to decrease the moisture of raw material.At this time,the total output of drier will be decrease greatly.It is not suitable in economy.Therefore customer should remove the moisture using machinery method(centrifugal or press) so as to decrease its moisture as possible in order to guarantee the drying operation can be carried out freely.

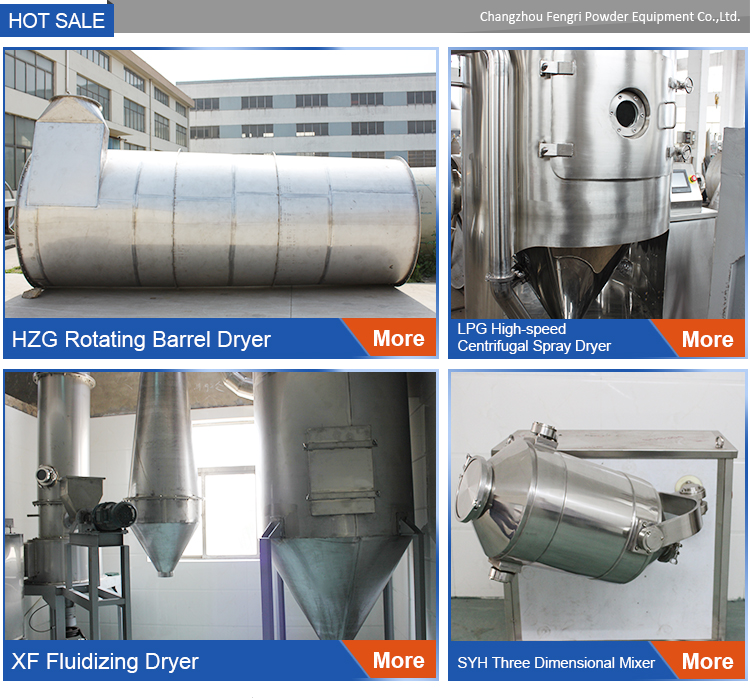

The equipment can meet different need of raw materials.Besides the mentioned raw materials in basic while carbon black,tea,catalyst of oxalic acid,promote agent m.d.m,catalyst,deposited carbon power, N-acetyl-sulfanily chloride, p-aminosalicylic acid, p-phthalic acid, diethyl aniline, titanium dioxide, active carbon, sodium fluosilicate, ammonium sulphate,power of silicon glue,synthesis resign,calcium sulphate,PP resign, aureomycin, sodium polysilicate, oral glucose, sodium sulphate, mine of sulphate, mine of phosphorus,BB blue, melting phosphorus fertilizer, tetracycline, ferric oxide, calcium carbonate, titanium ferric mine, copper mine,powder of white potato, tail coal, stearate, zein, medicine,medical agent,ferric oxide,less residue...

China

China